Rights Reserved - Free Access.

This digital object is protected by copyright and/or related rights. This digital object is accessible without charge, but its use is subject to written permission.

Unless expressly stated otherwise in the licensing conditions, you are free to make any of the acts permitted by your national copyright and related rights act, including browsing, printing and making a copy for your own personal purposes.

All other acts of reproduction and communication to the public are subject to the licensing conditions attached to the digital object.

ARMY BOOTS OF THE WORLD. REVIEWS

Important notice: we do not sell any boots! The prices are given for information purposes only!

Japan![]()

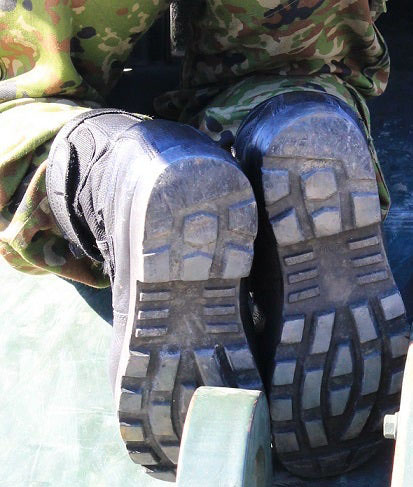

Japanese Combat Boots, Heat-Resistant, Type 3

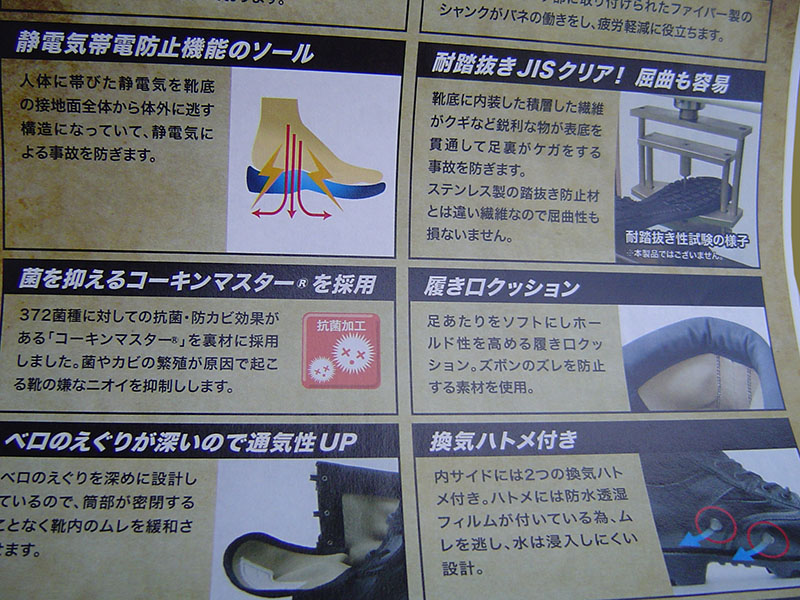

After the Japanese Army switched to Type 2 combat boots in 2002-2003, the "Type 3 Heatproof Boots" were introduced, retaining the basic appearance of the Type 2 boots, but with improved ventilation and other features.

The government specification includes: electrostatic protection, non-stick sole, Corkin Master odor control system capable of inhibiting 372 types of bacteria, textile with silver ions, high sole of 3-layer construction (highly elastic foam layer, then layers of soft and hard EVA, the tread itself is made of a single layer of rubber, with an officially approved pattern), two ventilation eyelets on the inside of the foot (with a waterproof breathable film to prevent moisture from getting inside the boot), elastic fiber shank to reduce foot fatigue.

In 2014, a civilian version of these Type 3 heat-resistant boots was introduced by Midori Safety in the Japanese market at a price of 30,000 yen (approximately US$195) per pair.

At first glance they look the same as the Type 2 army boots, but they have ventilation eyelets on the inside of both feet, the nylon and waterproof lining on the sides is thinner than the military boots, and the tailoring details of the upper are also slightly different. That said, their construction is much closer to the Heat-Resistant boots Type 4 (tropical boots) described below.

While there are some external similarities, the inner material of commercial heat-resistant boots differs from military boots. Among the disadvantages of commercial boots when worn in the field, as reported in Japanese forums, is the problem with drainage eyelets, which do not hold well and often fall out.

Rear side, compared to Combat Shoes Type 2. On the left are Type 2 military boots, and on the right are Type 3 heat-resistant boots (their distinguishing feature is horizontal stitching at the level of the Achilles tendon).

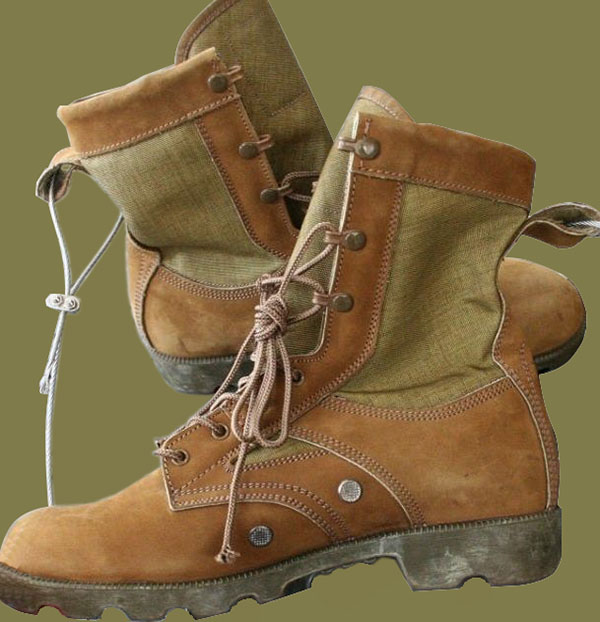

Japanese Tropical Boots (Heat Resistant Boots Type 4)

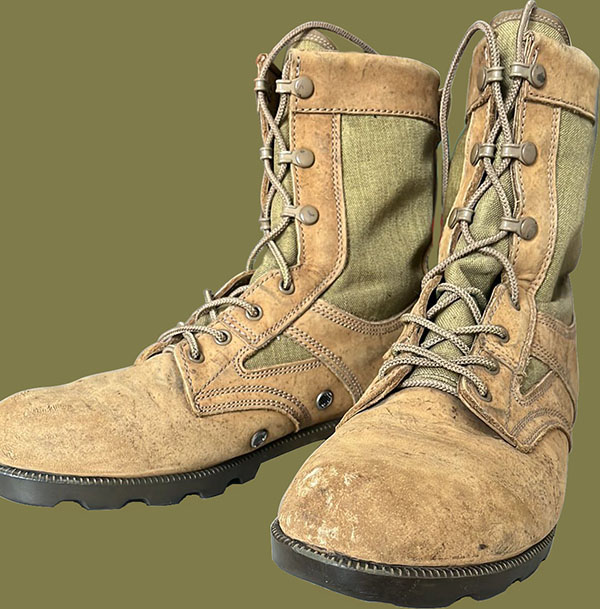

The Japanese Self-Defense Forces' brown tropical hot-weather boots were adopted for Japanese troops deploying to Iraq in late 2003.

These boots were made on the basis of Type 3 Heat-Resistant boot model, but the smooth black leather was replaced with suede, and they were named Heat-Resistant combat boots Type 4.

The lacing system of Japanese tropical boots consists of 3 pairs of quick lacing eyelets in the upper part and 4 pairs of simple round eyelets in the lower part.

On the inner side of the bottom there are two eyelets for ventilation and drainage of water trapped in the boots. As it is known, such drainage eyelets were used in American boots intended only for hot humid climate and were not used in desert versions of boots (to prevent sand and dust from getting inside), but the latest versions of American tropical boots are designed for both desert and jungle, made of suede and equipped with water drainage eyelets, so we can say that the Japanese combat boots manufacturers are in the trend of military footwear evolution.

The leather upper is not as rough and fleecy as in the boots of the U.S. Army, but not quite smooth, it is more like nubuck. No need to polish such shoes and increased resistance to scratches and minor damage - the undoubted advantages of this type of leather upper. Somewhat lower water resistance compared to smooth leather can be compensated by the use of water-repellent sprays or similar types of footwear aqua-stop impregnation soakers.

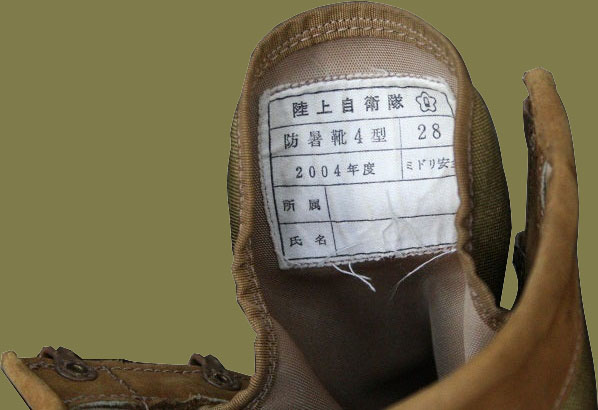

The markings on Japanese tropical boots are the same as on all modern military boots: a "sakura" sign with the Latin letter Q in the middle, an inscription of military affiliation (JSDF), boot Type (4), year of manufacture and size.

The out-sole fastening method is DMS, the tread pattern and heel padding are the same as in Type 2 general purpose army boots.

Japanese paratrooper boots, brown, Type 1

Airborne troop boots, unlike general army brown and black boots, do not use hooks to hook the laces. According to safety requirements, hooks are not used on paratrooper shoes because they can easily snag on slings and parachutists' equipment.

On the other hand, these boots have an increased number of the usual round lacing eyelets. The laces can thus be secured more securely. by customizing one of the many lacing patterns, perhaps skipping some pairs of eyelets to tie the laces, for greater comfort and fit.

Accordingly, it is also more difficult to remove such boots, and, as the Japanese paratroopers themselves joke: "This is because these boots cannot be removed after you have already put them on".

The laces are nylon, brown, an exact copy of the American ones, but shorter, less than 2 meters, and of very high quality.

The tread pattern of the sole is traditional Japanese, for general army boots.

The dense, multi-layered leather, overlays on the heel of the boot structurally ensured good fixation of the foot in the boot and protected it from sprains and small traumatic bruises.

Elements of the upper design and appearance of these boots clearly shows that they were created on the model of the first American "Corcorans" of the early 1940s, even the smooth polished leather of these boots reflects the desire of paratroopers to stand out from the general mass of soldiers and emphasize their status of elite units.

In the newer model, the simple round lacing eyelets at the top of the shoe have been replaced by 5 pairs of quick lacing eyelets, each secured with two rivets, while the bottom 4 pairs remain unchanged.

It is worth noting the unusual ways of fixing the pants inside the boot: these are soft rubber spikes or a flat rubber band with small holes on the cuff of the shoe top, performing the same function as the rubber band on modern black Japanese army boots of the Type 2 and 3.

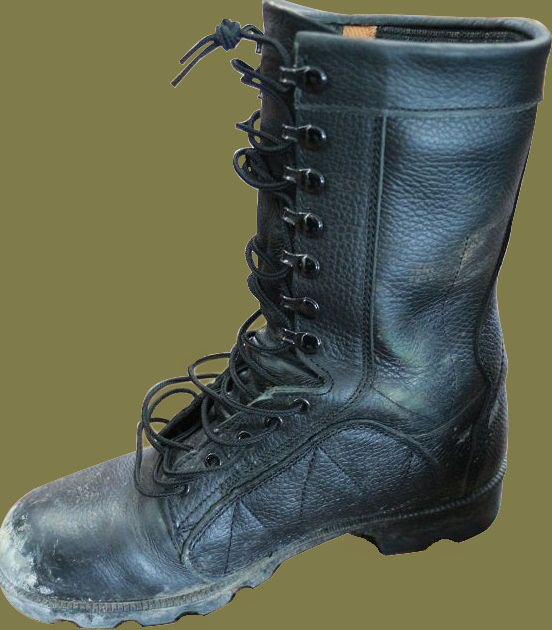

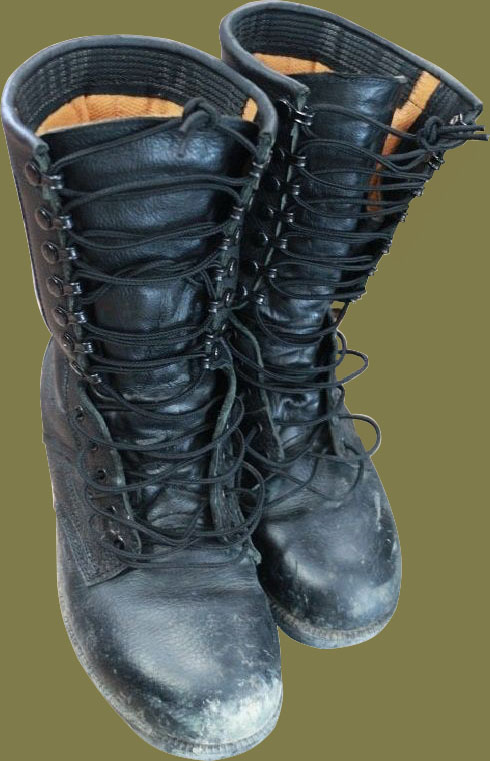

Japanese paratrooper boots, black, Type 1

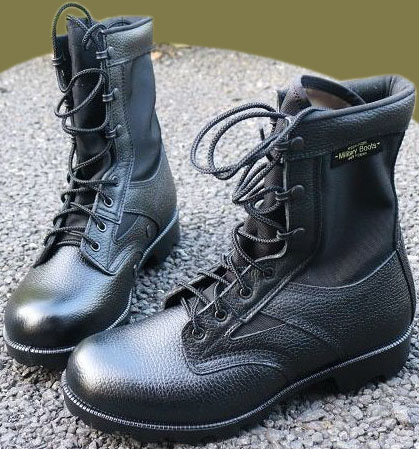

Around 2002-2003, around the same time that Type 1 brown military boots were replaced by Type 2 black military boots in the Japanese armed forces, the footwear for airborne troops was also updated.

They are similar in design to the army boots of general use, but fully leather, without textile panels on the sides, higher and with increased number of lacing elements: 5 pairs of simple round eyelets in the lower part, and 7 pairs of quick-lacing eyelets in the upper part, these groups of eyelets are separated by a structural cutout for greater flexibility when bending the foot.

From the outside they give the impression of being rather uncomfortable and bulky due to the heavy full-grain leather upper, an impression reinforced by protective leather overlays on the inner sides of the foot, reinforced with stitching.

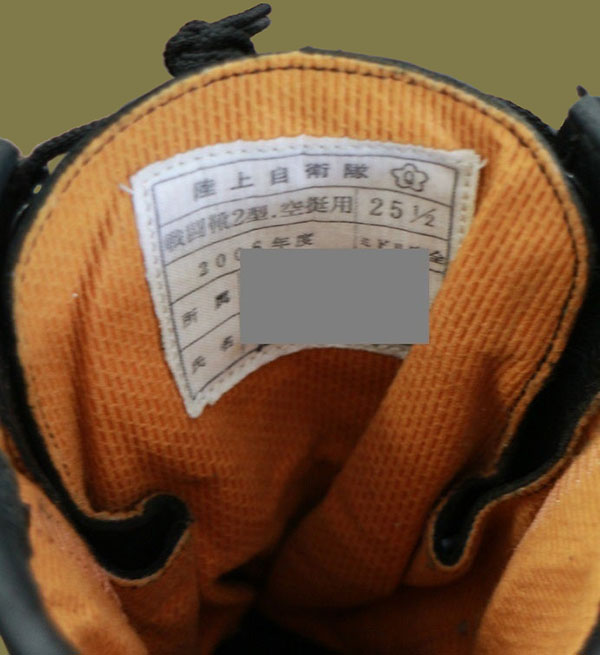

In the upper part of the boot top there is a voluminous soft leather cuff, rubberized strip to prevent the pants from slipping out of the boots, inside there is a standard textile lining of orange color. Military markings on the label inside the tongue, as well as the tread pattern of the out-sole does not differ from the general army boot.

Japanese paratrooper boots, black, Type 2 (modified)

The experience of using Type 1 paratrooper boots with full leather upper, additional leather overlays on the sides, received feedback from paratroopers, as well as the need to save money led to the appearance of a lightweight and simplified version of paratrooper boots.

The lacing system was left unchanged, the appearance of the boots was brought in line with the general army appearance, replacing the leather side panels with textile ones, and also removing additional protective leather overlays on the inner surfaces of the feet: as it turned out, they did not provide any additional special protection, but at the same time they weighed down the overall weight of the boot, without this element practically nothing changed in the end.

Japanese paratrooper boots, black and brown, Type 3

In line with the next update of the Japanese military boot lineup for general use from Type 2 to Type 3, a new model of tibs for airborne troops began shipping from 2023, at first these boots were black in color, with smooth leather

Then came the updated version and the new suede "coyote-tan" colors are already significantly different from those that until then were intended for the Airborne Forces.

The Japanese have taken into account the latest trends in the military footwear industry and the experience of the recent wars in Iraq and Afghanistan. The new boots are closer in upper design to the modern military boots offered to the US Army by leading sports shoe manufacturers such as Nike, Reebok, etc.

Very lightweight, with a minimum number of seams, suede elements in the most important places of the upper, ensuring the reliability of the construction and textile panels for ventilation and lightweight upper. Among the important innovations are the textile loops of the lacing system.

The manufacturers left the sole the same, with a heel and standard tread pattern, without experimenting with sneaker-type soles, as in European and American samples.

The result is light, comfortable, quick-drying, strong boots, which can be used as desert boots.

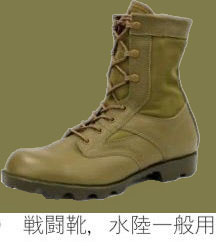

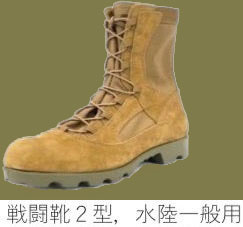

Japanese boots for the amphibious assault force

Specially for the members of the Japanese Amphibious Task Force, established in 2018, a kind of "combat boots for general amphibious use" (戦闘靴・水陸一般用 were adopted, similar in shape to the previous Type 2 combat boots, but with a green smooth leather upper, and textile inserts of the same color.

In the Japanese Self-Defense Forces, they were nicknamed "Zunda boots" because of their resemblance in color to rice cakes covered with green sweetened soybean paste-Zunda ("Zunda Mochi" or "Zunda mochi"), popular in the southern part of the northeastern region of Japan. ( Zunda Mochi, a traditional Japanese sweet made with mashed, sweetened edamame and mochi rice dumplings).

Naturally, water drainage holes are absolutely necessary on shoes for amphibious troops landing from the sea, just like any jungle shoes. Specificity of landing from the sea requires from shoes, where new water is constantly coming in, its quick drainage, so instead of the usual pair of large drainage eyelets, as on heat-resistant boots type 4, these boots have several smaller drainage holes.

Experience with these boots, which is sometimes visible in photos as well, shows that the original green color fades and turns beige, probably due to exposure to intense sunlight and seawater. It is also reported that these smooth leather boots do not have the same color shoe care products to match the specifics of use, so it is difficult to keep them in shiny condition like regular black leather combat boots.

The equipment specifications for waterborne units, as it appears to the developers, are often determined before the units themselves are formed, so it often ends up that the equipment does not really match the actual situation in a combat operation.

Therefore, a modified version of these boots appeared, already suede boots of the same color, and since 2022, the troops have been wearing the so-called "combat boots, amphibious specification" made of beige suede leather (ベージュのスエードレザーを使った「コンバットブーツ、水陸両用バージョン」。), similar to the heat-resistant Type 4 boots.

After the Self-Defense Forces switched from Type 2 to Type 3 boots, since 2023, paratrooper boots have also been available in the Type 3 model. Thus, both general army and paratrooper boots belong to this type.

Generally, there is some confusion with the classification of boots for amphibious use, and they are called "Type 2 combat boots for general amphibious use". This may be because they were originally only of the initial type, and after modification, they were called "Type 2, for general use on land and water"(戦闘靴・水陸一般用・フォローアップ).

Very similar in appearance are the aforementioned Type 3 combat boots for airborne troops.

Japanese military high-boots for armored vehicle crews

After the war, for crews of Japanese tanks and armored vehicles, boots with wide shanks and a belt buckle over them. It was believed that, compared to any boot, such a boot was easier to remove in an emergency, and would literally save the foot if it became locked inside an armored vehicle, caught on something, or in the case of a gunshot, shrapnel wound, when the speed of removing the boot for first aid was important.

These boots have an insert (gusset) in the upper part of the shank, which is fastened with a belt with a buckle, and in order to pull the foot out, it is enough just to unbuckle it. This is in theory, but as is often the case, in reality many crew members of Japanese tanks and armored vehicles preferred to wear their regular army boots.

The tread pattern of the sole is exactly the same as the brown army boots. According to Japanese sources, these boots were actually issued until the late 2000s, as the stockpile was used up.

In previous decades, the Japanese tank high-boots were freely sold in an assortment of sizes, and even now they can still be found on online auctions, but they are already quite expensive, and this upward trend in price is only going to get worse.

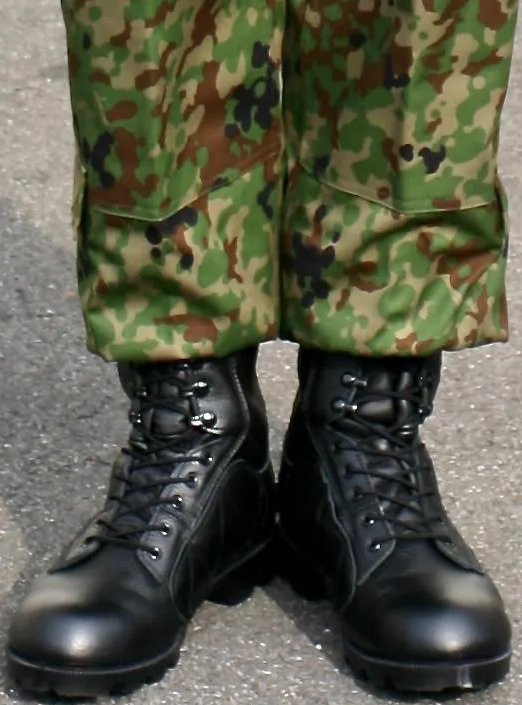

Japanese military boots, Type 2, for armored vehicle crews

In 2003, at the same time as the Type 1 brown leather boots were replaced with Type 2 black leather combat boots, the tank boots were also replaced with boots made of the same materials as the army boots - textile and leather.

However, instead of laces, they are fastened with 2 large Velcro straps (to make them easier to remove in emergencies), which made the new boots similar to ski boots. In addition, the use of Velcro makes it easier to adjust the shoes to the individual foot size in a cramped tank or armored vehicle.

They are actually very easy to remove and put on, compared to lace-up shoes. The downside of convenience is the well-known disadvantages of shoes on "velcro": the part of the clasp, which has hooks, very easily snags on itself all sorts of threads, fabric fibers and other small debris, and inside the armored vehicle can get caught on protruding structural elements and spontaneously unbuckle.

On the other hand, the thick smooth black leather upper, leather volume cuff on top, for a tighter fit, leather back strip, reaching to the very top, in combination with Velcro fastener overlays make this shoe more comfortable and safe, compared to the boots of the previous model, and textile panels of cordura on the sides, reinforced with a nylon sling, as in boots for jungle, slightly lighten the total weight and improve heat exchange and ventilation of the feet.

Perhaps due to the fact that tank and armored vehicle crews have to spend a significant part of their time working outside their vehicles rather than inside, the photos often show crew members not in tank boots, but in general-purpose military shoes, which also feel lighter and more flexible when worn.

The sole has a slightly different tread pattern than the general purpose army boots, a variation of the "Panama" type sole with longitudinal grouser teeth.

The reason for the difference between the tread patterns of tank and general army boots may be quite simple: while army boots are produced by "Midori Safety", shoes for tankers and armored vehicle crews are produced by "Aoki Safety".

Japanese military boots for amphibious armored vehicle crews

For Japan's recently established operational amphibious forces using the U.S. Marine Corps AAV-7 (Amphibious Assault Vehicle 7) tracked amphibious assault vehicles, green-colored boots are provided, very similar to the previously discussed black boots for tank and armored vehicle crews.

It is conceivable that when this model for amphibious armored vehicles is upgraded to Type 3, their smooth leather upper may be replaced with beige suede, and it is possible that the new type will have a side zipper instead of velcro.

Since they are designed for amphibious assault units, each boot has a pair of ventilation eyelets on the inside of the foot to drain water from inside the boot, like the jungle boots or Type 4 heat-resistant boots. The sole tread pattern is exactly the same as that of the previously discussed armor boots, which are also manufactured by "Aoki Safety".

Japanese Army Ski Boots, Type 1

The specification for these boots calls them "Cold-Weather Boots", compatible with military issue cross-country skis, but they are actually shoes for walking and skiing in snowy mountains, not for keeping feet warm in static use with a minimum of movement.

In creating these boots, the Japanese clearly drew on the experience of European armies operating in the Alpine region, particularly the Swiss, German, Austrian, and French armies - the appearance of the Japanese boots, the design of the sole, and even the tread pattern clearly indicate this.

Around the early 1980s, such ski boots were already in use, and they were black in color, like the Europeans, while the Japanese army at that time adopted the brown color of their combat boots.

These are boots made of thick smooth black leather, the construction is with a minimum of seams, because moisture penetrates the shoe most quickly through the holes from the stitching. Lacing method - 5 pairs of hooks, under the laces - overlapping leather "shutters", as on Swiss mountain boots, allowing to distribute and reduce the pressure from lacing on the foot instep. The upper of the boot ends with a small hinged cuff made of soft leather, as on flight boots, under which you can wrap the excess ends of the laces and hide them so they don't get in the way.

The method of attaching the sole is DMS, of dense solid polyurethane, as was fashionable in those years. The sole's rounded square-shaped rant protrudes slightly for attaching ski furniture, as on the Austrian Army's Kampfschuh Schwer, an old-style, hook-and-loop lacing system. The cutout on the back of the heel is also designed for attaching the ski furniture, as on the Norwegian boots of the 1977 model.

The tread pattern is essentially a variation of one of the French BMJA65 type of military boots.

As a Japanese man who has tried these boots nowadays writes on the forum: "I found them to be generally stiff and not at all protective against the cold! The team members didn't seem to like them. The soles are thin, uneven and flat, so they are slippery when walking in snow, but they are also quite difficult to walk in when walking on ordinary paved roads".

Japanese Army Ski Boots, Type 2

These Japanese boots are most similar to the Austrian Army's Kampfschuh Schwer new model, 2000s, German Kampfstiefel model 2005/07 or Danish.

The construction is quite sturdy, and they are also heavier than the previous model due to the multi-layer leather upper and the hard solid sole. Compared to the old ski boots, they are tall, padded inside with a more modern design, but the sole is still very hard and flat, making it difficult to walk on normal roads. The lack of cushioning in the sole and modern foam pads undoubtedly lengthens the "life" of the shoe, but also cause some inconvenience to the wearers of such hard shoes.

Lacing system: a pair of D-rings at the very bottom, two blocks of three pairs of hooks, between which there is a lock to block the tension of the laces, as on later Austrian and German boots.

The tread pattern of the sole is almost the same as on the previous model, with minor differences, the protrusion on the ridge of the sole and the groove on the heel for ski bindings also remained unchanged.

Sources of images and data:

https://ameblo.jp/kaz721023/entry-12233300574.html

https://img01.militaryblog.jp/usr/n/e/w/news/ARDB-G-8.jpg

https://twitter.com/Daiki_RTA04/status/1585772931401265153

https://www.ranger.ne.jp

https://jp.mercari.com

https://page.auctions.yahoo.co.jp

https://paypayfleamarket.yahoo.co.jp

https://aucview.aucfan.com/yahoo/w1091371185/

Exclusively for cartalana.com

We have much more interesting information on this site.

Click MENU to check it out!

∎ cartalana.com© 2009-2025 ∎ mailto: cartalana@cartalana.com