Rights Reserved - Free Access.

This digital object is protected by copyright and/or related rights. This digital object is accessible without charge, but its use is subject to written permission.

Unless expressly stated otherwise in the licensing conditions, you are free to make any of the acts permitted by your national copyright and related rights act, including browsing, printing and making a copy for your own personal purposes.

All other acts of reproduction and communication to the public are subject to the licensing conditions attached to the digital object.

ARMY BOOTS OF THE WORLD. REVIEWS

Important notice: we do not sell any boots! The prices are given for information purposes only!

Japan![]()

Japanese Army boots, Black, Type 2

The Japanese, like other Southeast Asian peoples (Koreans, Vietnamese, Chinese...) who have been traditionally cultivating rice, are very diligent, meticulous, and attentive to details. Such peculiarities of national character traits have been developed over decades and centuries, because rice cultivation is not an easy task. It is a rather capricious crop, and to get a good harvest requires well-coordinated teamwork, strict adherence to subordination and unconditional obedience to elders, long-term repetitive routine actions. Such peculiarities of national character allow to perfect almost any idea, mostly borrowed from the West. Unlike the previous model brown boots, Japanese developers of next generation black boots took American "jungle boots" as a model, not paratrooper boots, they rethought the idea and made a lot of efforts to improve them. Thus, the Japanese Army Black Combat Boots Type 2 appear to be a kind of "jungle boots" with a "Kevlar"-like lining. The same model (with improved sole characteristics) issued as a personal item is called "半長靴3型 (Boots Type 3)".

First of all, the upper leather of the new boots is not smooth as in the original, but "grained" ("shagreened"), which allows for more economical use of materials. After processing by "shagreening", even medium quality leather becomes stronger, more flexible, elastic, resistant to damage and adverse factors.

The main "framework" of the boot, which bears the loads - toe, heel, side panels, rear side and soft cuff on top - is made of leather.

For more cushioning, a better fit of the boot top to the leg. and to keep the pants inside the buckled boot, the Type 2 black Japanese military boots feature a striped elastic band sewn to the inside of the leather cuff.

The original American jungle boots are made of leather only the lower part of the foot (toe, docked with the heel), as well as the frame of the lacing system, and all other elements were, depending on the model, made of tarpaulin or nylon (to speed up the drying of a wet boot).

Unlike the American model, Japanese black boots Type 2 have no eyelets to drain the water trapped inside - after all, they are all-army, and are designed not only for hot, humid climate, shoes for which should quickly get wet and as quickly dry.

The Japanese have a very strong rear part of the boot, which securely fixes the foot: a wide protective strip of leather is sewn on the back, reaching up to the soft leather cuff at the top.

The Japanese made the side panels from strong, flexible, resistant to damage, breathable nylon-cordura, inside the boot - bright orange textile lining for cushioning, wearing comfort, better heat exchange and evaporation from the feet.

The cordura tongue flap is almost blind, sewn almost to the top of the lacing - its edge is located between the top two eyelets of the quick lacing system.

The lacing system itself has also changed: there are four pairs of round simple eyelets at the bottom, then a shaped cutout for easy bending of the foot, and three pairs of fast lacing eyelets at the top. This is a very successful layout, proving comfortable and effective for quick lacing up and taking the shoe off.

The outsole tread has a modified, more symmetrical "Panama" pattern on the heel, which is characterized by self-cleaning properties (when drying, soil stuck in the sole grooves quickly falls off) and excellent traction on a wide variety of surfaces, from wet grass to soil and sand, from gravel to asphalt.

The back edge of the heel is reinforced, with 3 protruding strips of fine grooving between the heel and the foot for better grip. This is a very successful and well proven sole.

In the last 10 years these boots have been called Type 3 while retaining the appearance of Type 2 boots: as far as can be judged from reports on Japanese forums, the changes are minimal and are related to improving the anti-static and thermal protection characteristics of the sole.

If you look closely at the sole of Japanese boots, you can see small dots, circles, on the flat surfaces of the protruding grousers of the sole tread. These are traces of the process of direct molding of the sole, the so-called "tidal method of fastening", or DMS. In this process, the sole is attached to the leather upper on a special machine, unique for each size or half-size, by hot molding it into a special mold.

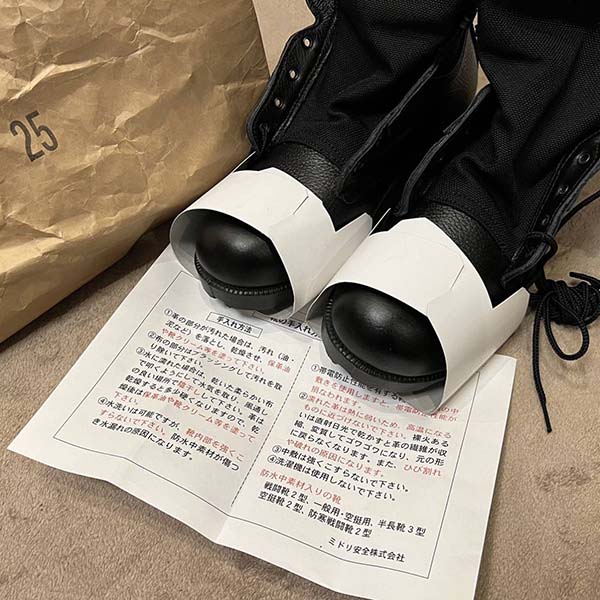

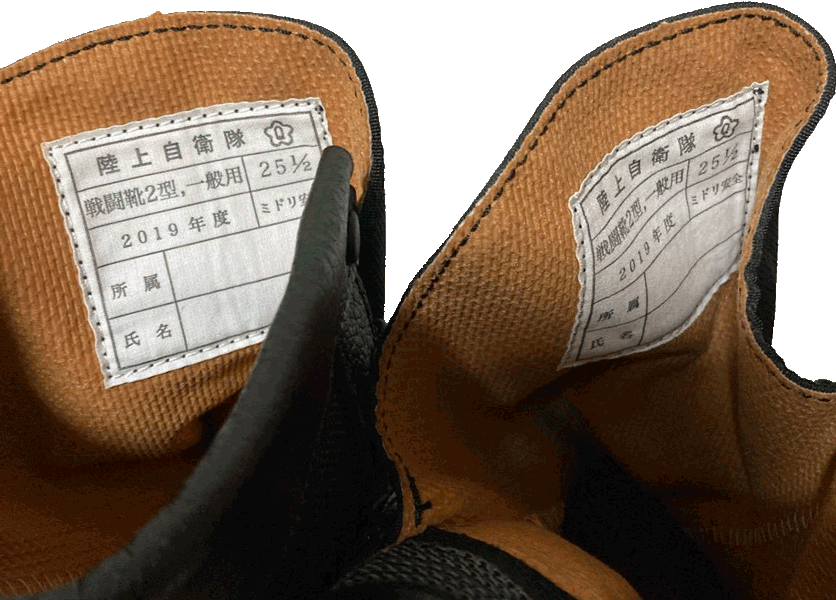

The marking on the tongue contains a military logo with a cherry blossom, the inscription 自衛隊 (Jieitai) - Japan Self-Defense Force, size, boot type (2 or 3), year of manufacture and other identifying information.

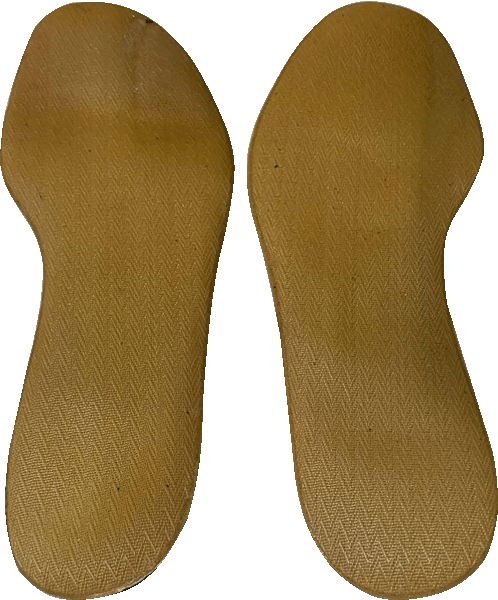

The insoles of Japanese military boots

On the left is a "Saran" type insole, which came with the old brown boots. Instead of mesh, the Japanese insole fibers feature a "twill" (fine zigzag) weave. These insoles were thin, smooth, created a very thin layer of air and, if you believe the reviews of Japanese soldiers about them, almost no cushioning. Compared to the one-sided American or European (German, British, Dutch...) similar insoles, the Japanese one is double-sided and can be flipped and swapped between the left and right boots. Identification information was stamped on the insoles in the form of a stamp in paint, with the year of manufacture, size and information about the manufacturer.

The second insole, in the middle, is used in the black boots of the next model, Type 2, it is already made of two types of foam material, bright yellow, with dot perforations, for the forefoot, and bright orange, with shaped relief, thicker and denser - for the heel part. Similar insoles are used in modern sports shoes, everyone is familiar with them, so there is no point in reviewing them in detail.

The most advanced insoles used in the modern Japanese military boots (Type 2 and Type 3) are black and red one, shown on the right. The top of the Japanese military insole is made of wear-resistant textile (nylon). The edge of the insole is edged with nylon thread. If we look at the underside, we can see that the front part is made of a fine porous material resembling felt, the back part is made of shock-absorbing porous material with large round holes for ventilation and comfortable microclimate inside the boot when walking. Two strips of durable material are glued and sewn on the midfoot and heel to prevent damage to the insole. The stitching on the heel is oval. On the foot it is zigzag. Of the three types of insoles presented, these are the most advanced, and, among other things, have an additional anti-static function.

Each insole is labeled with the same identifying information as the contract military boot itself: 自衛隊 (Jieitai), a sakura sign with the letter Q inside, size and year of manufacture, and manufacturer information.

While these insoles are good enough, and will fit almost all wearers of Japanese boots, it is still believed that for personal use, some people are better off choosing insoles individually, perhaps orthopedic insoles, specifically for the characteristics of their feet.

Twisted elastic bands with hooks to secure pants to boots

As you know, the proper way to wear pants with military boots is to wear them over the top, not tucked into the boots. This is even specifically stated on the "Instruction Tag" for American jungle boots: 4. Trouser should be worn out-side of boot.

The boot then fits snugly around the leg, no excessive pressure is created by the crumpled fabric of the pants, and no water, small foreign objects or insects can get inside. To tighten the bottom of the pants, slings are provided, which are tied over the boots. But they are not always convenient, they can come undone, or on the contrary, the knot can be tight.

Therefore, Americans have invented a simple and convenient means of solving this issue - twisted elastic bands on hooks, which are easily fastened on the boots over the lacing and as quickly and easily removed. The bottom of the pant leg is simply tucked underneath the elastic at a comfortable height for the wearer.

The Japanese military uses elastic bands identical to the American, Swiss, etc...

It's amazing how many different names these rubber bands have gotten in English: Military Boot Straps, Army Trouser Twists, Elastic Boot Bands, Blousing Straps, Military Leg Ties, Army Garter Straps, Legging Rope, Bungee Twisters (with Metal Hook for Pants).

In terms of shoe care, in the Japanese military, as well as in Western armies, the most commonly used shoe polish is either wax shoe polish ("KIWI" polish) or Japanese black emulsion shoe polish (乳化性靴クリーム).

Copies (replicas) of the Japanese Type 2 combat boots

There are various copies of Japanese military boots at different prices. The material for the upper of the boots can be natural or artificial leather. The surface of the leather has a shagreen surface, and the lining is made of different materials and looks more or less similar to government boots. The photos below show a sample of a more expensive and similar to the contract original copy

These replicas are easily distinguishable from the original by the sole: the replicas are made of (poly)urethane rubber of varying degrees of rigidity, with a "Panama" tread pattern to avoid lawsuits from the government for using a tread pattern patented and used only by the Japanese military.

For comparison, the original sole of the Japanese Army contract boots:

The copy has the heel at the back looking like this:

The heel of the original (labeled 自衛隊 (Jieitai)) Japanese military boots, on the contrary, has an additional overlay, so the back edge of the heel is flat, and you can clearly see from the photo that the material of the heel and the sole in general is dense, strong, wear-resistant.

The more expensive replica boots on the market, thanks to expensive equipment, use an "easy bond" type polyurethane adhesive, which provides a strong bond that prevents the sole from peeling off. To reduce the cost of packaging, sometimes there is no box and the boots are sent even in a plastic bag.

The upper edge of the replica shoes is made of a material that resembles a thickened sponge. The lining itself is made of a yellow, cheaper textile material. On commercial products, the label is left white, blank, with no writing.

On original Japanese military boots: cushioning rubber strip inside the leather cuff of the shoe upper, orange quality sweat-wicking lining, and a label with all the correct identifying inscriptions as discussed above.

The lining and outer surface may have dirt, stains, wrinkles and creases from the manufacturing process. In addition, the rubber outsole may have chips or air bubbles due to improper padding, which can affect performance and longevity.

The weight is also less than the original military boots and the overall construction may be somewhat lackluster. When buying copies, you should always pay attention to the quality of workmanship, it can vary greatly, and compare to the original contract boots.

Finally, copies usually lack anti-static soles and flame retardant treatments.

Sources of images and data:

https://ameblo.jp/kaz721023/entry-12233300574.html

https://item.rakuten.co.jp

https://page.auctions.yahoo.co.jp

https://paypayfleamarket.yahoo.co.jp

https://www.amazon.co.jp

Exclusively for cartalana.com

We have much more interesting information on this site.

Click MENU to check it out!

∎ cartalana.com© 2009-2025 ∎ mailto: cartalana@cartalana.com