ROYAL AIR FORCE. COMMON CORE AND DEPLOYMENT SKILLS AIDE-MEMOIRE

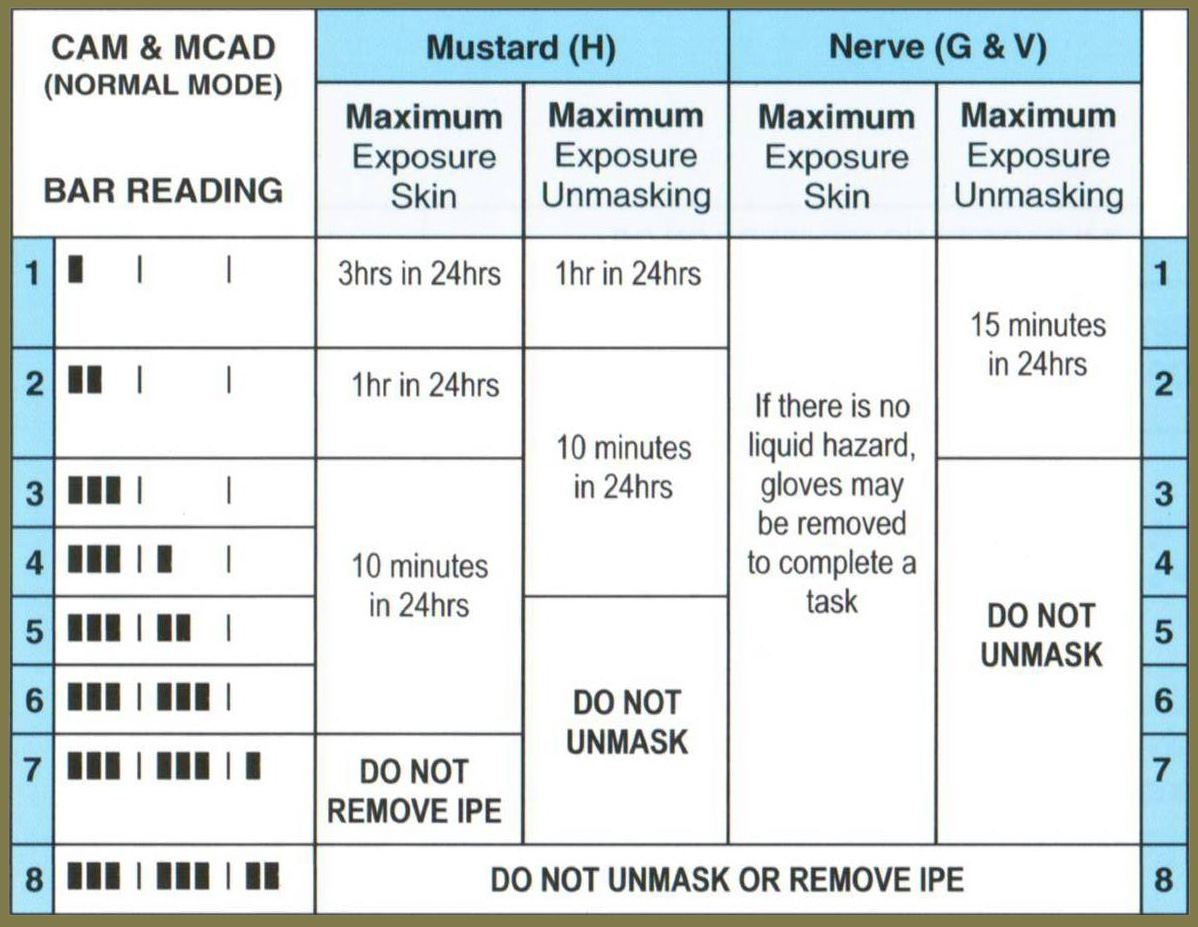

CHEMICAL AGENT MONITOR (CAM) AND COLPRO CAM LOCAL COMMANDER'S GUIDE

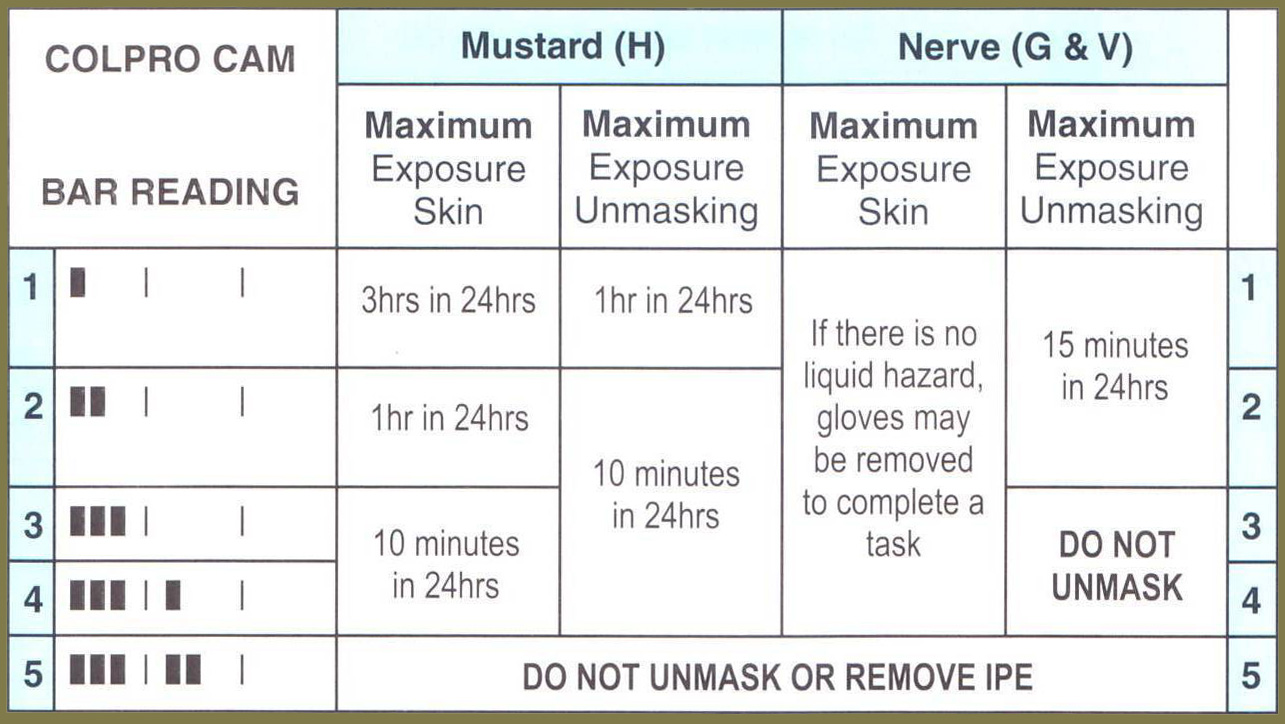

◉ CAM and COLPRO CAM monitor for Nerve (G and V) and Mustard (H) agent vapours. They will only respond to V agent temperatures above +5°C.

◉ Use detector paper on suspicious liquids. If skin contamination by liquid agent occurs procedures must be implemented immediately.

◉ UNMASKING IS RISKY. All unmasking in the presence of any hazard should be avoided unless OPERATIONALLY ESSENTIAL. Successive exposure will increase the risk.

◉ When using the Maximum Exposure Time Guide:

● DO NOT unmask or remove IPE without Local Commander's approval.

● Always take the highest reading when the display is fluctuating.

● DO NOT unmask or remove IPE if the bar display is increasing.

● Take frequent readings while troops are unmasked.

● Exposure times within each 24hr cycle can be continuous or broken down into smaller periods providing the maximum exposure time is not exceeded.

● After a total exposure time in a 24hr period has been reached and the hazard persists, wait 24hrs before further exposure.

● Note that the Maximum Exposure Time Guide is for all locations.

◉ If a 1 bar reading does not clear the display in 15 minutes, check background with RVD. If RVD shows clear, carry out unmasking drills.

MAXIMUM EXPOSURE TIME GUIDES FOLLOWING A CHEMICAL ATTACK

CAM and MCAD (Normal Mode) Mustard (H) and Nerve (G & V)

MCAD (Miosis Mode) Nerve (G & V)

| MCAD (Miosis Mode) | Mustard (H) | Nerve (G & V) | |

| Positive Response | Not Applicable | If there is no liquid hazard, gloves may be removed to complete a task | 1-3hrs in 24hrs |

COLPRO CAM

Mustard (H) and Nerve (G & V)

Sector and Station HQs require the following information:

◉ Enemy. (Strength and location).

◉ Casualties.

◉ UXO. (Location).

◉ Fire. (Location).

◉ Secondary fire hazards. (Ruptured gas mains, electricity cables, fuel storage systems and pressurised gas containers).

◉ Damage. (Weakened buildings). NBC contamination. (Present or not).

Not all fire alarms are connected to reporting centres. It is therefore essential that, after using a fire alarm, a telephone or radio call be made. Following an enemy attack, the routing of calls may be through the GDCC or other designated control centre. Specialist firefighting support may not always be available as a result of higher priority tasks.

THE FOLLOWING DETAILS ARE REQUIRED:

◉ Number, rank, name.

◉ Location of fire.

◉ Type of fire.

◉ Casualties or missing personnel.

◉ Additional hazards.

MAKE SURE THAT YOU KNOW:

◉ The emergency procedures.

◉ The evacuation routes.

◉ Where alarms are located.

◉ Location of extinguishers.

BASIC FIREFIGHTING PRECAUTIONS

◉ If safe to do so, fight fire from upwind, do not enter the smoke.

◉ Ensure you have an unrestricted means of escape.

◉ Ensure that smoke in the building is not circling back along the ceiling to cut off your escape.

◉ Keep low and behind the extinguisher.

◉ Make use of walls for added protection from heat.

◉ If fire is beyond your control, evacuate area.

◉ Proceed to the assembly point, where a nominal roll will be called.

◉ Always call the Fire Service, even if the fire is apparently extinguished.

CLASSES OF FIRE

There are many types of combustible materials that can be involved in a fire. These are grouped into the following 4 classifications:

◉ Class A (Solids). Wood, paper, textiles.

◉ Class B (Liquids). Petrol, oil, paints, fats, waxes. Class C (Gases). Piped domestic gas mains. Cylinders of propane, butane, acetylene, hydrogen, etc.

◉ Class D (Metals). Magnesium alloys.

ELECTRICAL FIRES Electrical fires do not constitute a class of their own. When dealing with a fire involving electrical equipment it is essential to:

◉ Isolate the electrical supply.

◉ Use an extinguishing media appropriate to the material that is burning.

When the electrical supply cannot be isolated with certainty, or if the electrical appliance is of the type that retains an electrical voltage after isolation, a non-conducting firefighting media, such as carbon dioxide (C02) or dry powder, should be used.

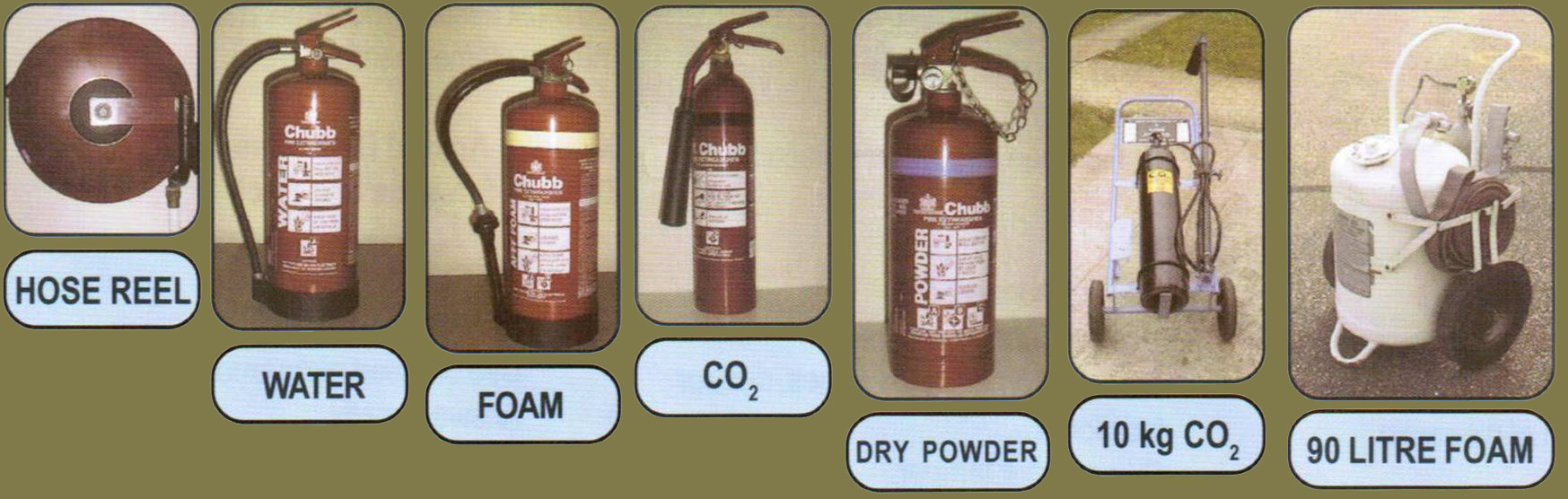

MOD buildings and installations are scaled and issued with hose reels or extinguishers appropriate to the role of the building and for any fire risks or special processes carried out. It is essential that personnel can identify and select the correct extinguishing media appropriate to the class of fire, these are:

◉ Class A (Solids). Water in the form of a jet or spray.

◉ Class B (Liquids). Foam, C02 or dry powder. DO NOT use water.

◉ Class C (Gases). Firefighting should be left to the Fire Service.

◉ Class D (Metals). These are specialist fires and should only be dealt with by the Fire Service, unless specifically trained.

WALL-MOUNTED FIRE HOSE REELS

Wall-mounted fire hose reels may vary in make and design. Some may require a main water valve to be manually opened, while others automatically open the water supply when the drum is swung out or when the hose is run out. Regardless of the type and make, the following sequence of operations is to be carried out:

◉ Ensure the water supply is fully open as indicated on the hose reel operating instructions.

◉ Run out adequate hose to reach the fire, assistance may be required when negotiating doorways and corridors.

◉ Water discharge is controlled at the nozzle either by valve or control collar.

◉ When using water as an extinguishing media it should be directed at the base of the fire to cool the burning materials. It should not be used on liquid fuel fires or powered electrical appliances.

◉ Do not place yourself at risk and only attempt to fight the fire if safe to do so.

To conform with British Standards and European Legislation Standard all extinguishers are red in colour. However, each type of extinguisher is designated by a coloured band

9 LITRE STORED PRESSURE WATER FIRE EXTINGUISHERS (ALL RED)

The operation of a stored pressure water extinguisher is as follows:

◉ Release nozzle from its clip.

◉ Pull out the safety pin.

◉ Aim the nozzle towards the base of the fire and squeeze the carrying and operating levers together.

FOAM BASED FIRE EXTINGUISHERS (CREAM BAND)

The operation of a stored pressure foam extinguisher is as follows:

◉ Release the branch pipe from its clip.

◉ Pull out the safety pin.

◉ Aim the nozzle towards the fire and squeeze the carrying and operating levers together. Foam should be applied with a sweeping motion to cover all flammable liquid. To prevent splashing do not aim the foam jet directly into fuel.

2/5 kg CARBON DIOXIDE (C02) FIRE EXTINGUISHERS (BLACK BAND)

The operation of a C02 extinguisher is as follows:

◉ Remove the safety pin.

◉ Point discharge horn at fire.

◉ Apply the C02 gas cloud across the flame area.

◉ As there is a risk of cold bums do not hold exposed metal parts of the extinguisher.

◉ C02 extinguishers are not to be used to make an area inert when flammable vapours are present due to the presence of static electricity build up at the discharge horn.

◉ Be aware that on discharge the extinguisher is very noisy.

2/6/9/12 kg DRY POWDER FIRE EXTINGUISHERS (BLUE BAND)

The operation of a dry powder extinguisher is as follows:

◉ Hold upright.

◉ Remove the cover from the nozzle.

◉ Pull the safety pin.

◉ Aim nozzle at base of fire.

◉ Squeeze levers to operate.

◉ Release levers to interrupt discharge.

◉ Dry powder should be applied with a sweeping motion to cover all the flammable area.

10 kg C02 TROLLEY Mk 2 EXTINGUISHER (ALL BLACK)

The operation of the 10 kg C02 Trolley Mk 2 Extinguisher is as follows:

◉ Release retaining clamps.

◉ Uncoil hose.

◉ Extend applicator to required length and secure the

knurled locking collar, ensure the nozzle is in alignment with the control valve lever.

◉ Open C02 Cylinder Valve by turning hand wheel fully anti-clockwise.

◉ Direct applicator horn/nozzle towards the fire.

◉ Squeeze lever to control discharge of C02.

When operating a 10 kg C02Trolley Mk 2 Extinguisher the following points should be noted:

◉ As there is a risk of cold burns do not hold exposed metal parts of the extinguisher.

◉ C02 extinguishers are not to be used to make an area inert when flammable vapours only are present, due to the presence of static electricity build up at the discharge nozzle/horn.

◉ Failure to correctly secure the knurled locking collar may result in uncontrolled extension of the applicator by gas pressure causing damage or possible injury to personnel nearby.

◉ Be prepared for jet reaction when using telescopic applicator, particularly when fully extended.

90 LITRE FLUOROCHEMICAL MECHANICAL FOAM (ALL WHITE)

The operation of the 90 litre Foam Extinguisher is as follows:

◉ Wheel the extinguisher as close as possible to the fire as radiated heat will allow.

◉ Remove the discharge hose and run it out to form a loop, returning to the extinguisher.

◉ Ensure the branch pipe on/off valve is closed.

◉ Open the Air Cylinder Valve fully in an anti-clockwise direction to pressurise the system, whilst maintaining a firm hold on the branchpipe.

◉ Briefly operate the branchpipe on/off valve to expel air in the system before approaching the fire zone to ensure media is available.

◉ Apply the foam to the fire at about waist height, moving the jet from side to side across the whole fire.

In order to assist fire crews at an incident all personnel are to be sufficiently familiar with the use of hydrants and associated equipment. The hydrants are designed as a means of tapping the water mains system for firefighting purposes. Hydrants are identified by means of a marker plate:

◉ The bottom number indicates the distance from the marker plate to the hydrant cover in metres. The top number is the size of the water main in millimetres.

◉ Hydrant covers are a yellow metal plate, the underside should be fitted with a plate indicating which direction to open the on/off valve.

◉ The hydrant pit houses the outlet valve and the on/off valve.

STANDPIPE, HYDRANT KEY AND BAR AND FALSE SPINDLE

In order to bring water from below the ground to the surface the following equipment is required:

◉ Standpipe. This is fitted to the outlet of the hydrant. It has a double outlet head, however, should only one outlet be required a blank cap may be fitted. Release lugs are fitted at the top of the outlets.

◉ Hydrant Key and Bar. The hydrant key and bar is for removal of the hydrant cover and operation of the on/off valve.

◉ False Spindle. In order to protect the soft metal of the hydrant on/off valve the spindle is fitted.

HOSES

Water is transferred from hydrants using a firefighting delivery hose as follows:

◉ Delivery hose comes in 2 sizes, 70mm x 25m lengths and 45mm x 25m lengths. Delivery hose from a hydrant to a fire appliance should be 70mm.

◉ Delivery hose is fitted with instantaneous couplings.

◉ Delivery hose may be conventionally rolled or Dutch rolled.

HYDRANT OPERATION

The hydrant is set up for operation in the following manner:

◉ Remove hydrant cover plate using the hydrant key and bar.

◉ Fit standpipe to outlet, fit blank cap as required to standpipe.

◉ Fit hydrant key and bar to false spindle.

◉ Operate on/off valve allowing water to flow briefly. This will ensure that debris does not enter the hose and confirms water flow.

◉ Connect delivery hose to standpipe.

◉ Run out delivery hose to directed destination, using either a conventionally or Dutch rolled hose.

◉ On receipt of visual or oral signal turn on hydrant.

EXAMPLES OF FIREFIGHTING APPLIANCES

You must assume that all radio transmissions are monitored. The key elements to remember are:

Security, Accuracy and Discipline (SAD).

Rhythm, Speed, Volume and Pitch (RSVP).

DO:

◉ Use your call-sign at the start of a transmission.

◉ Use only authorised nicknames and codewords.

◉ Answer calls promptly.

◉ Think before transmitting.

◉ Maintain constant radio watch.

◉ Keep messages brief, clear and logical.

◉ Use pro-words.

◉ Authenticate when a spoof message is suspected. DO NOT:

DO NOT:

◉ Use individual mannerisms.

◉ Use slang or jargon.

◉ Transmit aircraft types, roles, loads, names, units or locations in clear.

◉ Swear or lose your temper.

◉ Violate radio silence (unless operationally necessary).

PRO-WORDS:

Hello - Used to alert the radio net.

This is - Indicates identity of calling station.

Over - End of my message, reply required.

Send - I am ready to receive your message.

Roger - Message received and understood.

Say Again - Repeat all or part of message.

Out - End of my message, no reply required.

Contact wait out - In contact with enemy, report to follow. Radio silence enforced, until Contact Report sent.

Figures - Groups of numbers sent digit by digit

I spell - Used in conjunction with the phonetic alphabet.

Grid - Used before any grid reference, whether in clear or code.

Radio check - Repeat how you receive my transmission.

OK - Communications satisfactory.

Weak - Your transmission is weak.

Nothing heard - No transmission received.

AUTHENTICATION TABLE

" Hello C34 this is 40 authenticate 3C over."

"C34, 35 over."

"40 correct out."

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | |

| A | 57 | 64 | 91 | 82 | 46 | 39 | 74 | 13 | |

| B | 76 | 48 | 54 | 15 | 66 | 85 | 93 | ||

| C | 21 | 97 | 35 | 78 | 31 | 12 | 84 | 49 | 53 |

| D | 25 | 96 | 14 | 67 | 83 | 51 | 32 | 47 | |

| E | 92 | 41 | 65 | 23 | 75 | 16 | 81 | 34 |

Then stroke through 35 to indicate that it has been used once and is not to be used again. Should another station request call-sign to authenticate re-using 3C, no reply should be offered and 'spoof signal precautions should be taken in accordance with local orders.

Intentionally Blank

We have much more interesting information on this site.

Click MENU to check it out!

∎ cartalana.com© 2009-2025 ∎ mailto: cartalana@cartalana.com