Rights Reserved - Free Access.

This digital object is protected by copyright and/or related rights. This digital object is accessible without charge, but its use is subject to written permission.

Unless expressly stated otherwise in the licensing conditions, you are free to make any of the acts permitted by your national copyright and related rights act, including browsing, printing and making a copy for your own personal purposes.

All other acts of reproduction and communication to the public are subject to the licensing conditions attached to the digital object.

ARMY BOOTS OF THE WORLD. REVIEWS

Important notice: we do not sell any boots! The prices are given for information purposes only!

USA ![]()

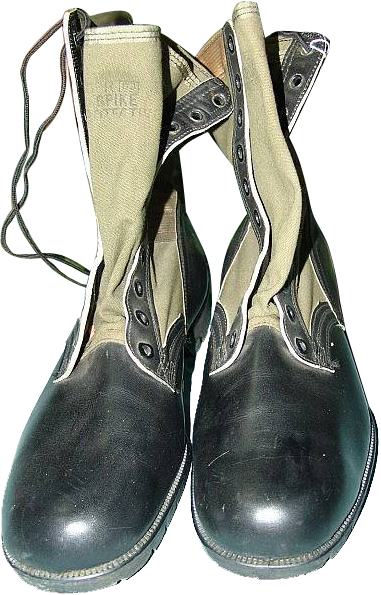

US "Jungle" Boots of the Vietnam War Era

The canvas and leather Tropical Combat Boots were developed at the end of the Second World war (1944) and put into manufacturing in summer 1945 - too late for mass production. The next war in Korea (1950-1953) took place on the territory of temperate to cold climate, not in hot, wet and humid areas, so the Pentagon apparently had very little interest in the further development of "jungle" boots concept.

In some other countries the situation was some different. The "Palladium®"-made canvas/rubber "jungle" boots (based on the concept of American M-1942 "jungle" boots) were widely used by the French colonial troops during the First Indochina war (1946-1954). These "Palladium®"-type boots came in different variants and were also used during the Algerian war (1954-1962).

But the situation radically changed during the conflict in Vietnam. Already the beginning of involvement of US military in Vietnam showed the urgent necessity of the specialized footwear for tropical climate and gave new life to the old idea. In the early years of that conflict, some U.S. military units were supplied with the "Okinawa boots" (M-1945 Tropical Combat Boots), but most of them had to use their conventional standard all-leather combat boots, which actually were not suited to the conditions of hot, wet and humid tropical climate.

Some U.S. advisors, which were arriving to Vietnam from the American military base in Okinawa, Japan, wore the so-called "Okinawa boots" of the WW II, some stocks of these "jungle" boots were shipped to Vietnam and issued there. But soon it was found out that these boots performed quite poorly after the 20 years of storage and soon tended to deterioration. Other advisors had to wear all-leather combat boots as well as most the U.S. Army and U.S.M.C. troops at that time.

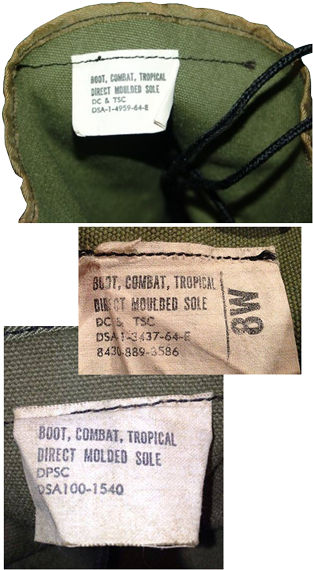

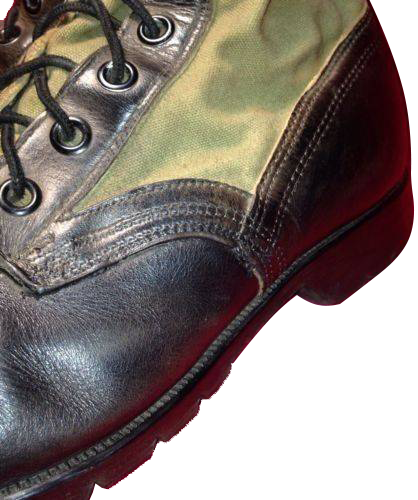

The model of the U.S. military "jungle" boots, which embodied the experience of using the previous models "jungle" boots and the improvements developed for tropical climates footwear over the last 20 years was tested in 1962-1965 and adopted in the year 1965. It became widely known as "M-1966 (M-66) Jungle Boot". The developers of this model decided to get rid of the double-buckles leather cuffs on the top of the boots; the design of these boots provided the toe and the counter made of black leather, the upper made of cotton canvas duck with nylon reinforcements for the boot's neck. The nomenclature of M-1966 (M-66) "jungle" boots was "Boots, Hot Weather" - "Boot, Combat, Tropical, Mildew Resistant".

The new M-66 "jungle" boot featured "Vibram®"-type lugged composition rubber DMS (Direct Molded Sole, i.e. strongly vulcanized to the leather toe and heel cap). Actually the DMS technology was developed by "Wellco®" ("Ro-Search®" Lab),

one of the major contractors of the U.S. Ministry of Defense (U.S. MoD), which produced about 5 thousand pairs of "jungle" boots per day in the mid of 1960s. As the Direct Molded Sole was part of the "jungle" boots design, this technology was licensed to multiple other U.S. MoD contractors for additional production, because there was urgent need in mass production of these boots for American troops in Vietnam.

These boots were intended to be used with removable ventilating "SARAN®" insoles made of fused layers of PVDC (Polyvinylidene chloride) plastic mesh screen, first invented back in the year 1942.

These boots also featured built-in double screened eyelets at the inside shank of each boot. These brass drainage eyelets were intended to allow water to drain out and to permit air to reach the feet inside the boots. The early version "jungle" boots with DMS featured sunken ventilation and water drain ports (Figure 1), because these first type boots were supplied with removable rubber plugs, which could be used to prevent ingress of outside water into the boots, in case of need.

Figure 1

This feature proved to be impractical, so next versions of "jungle" boots lacked these rubber taps, and the form of brass drainage and ventilation eyelets was simplified.

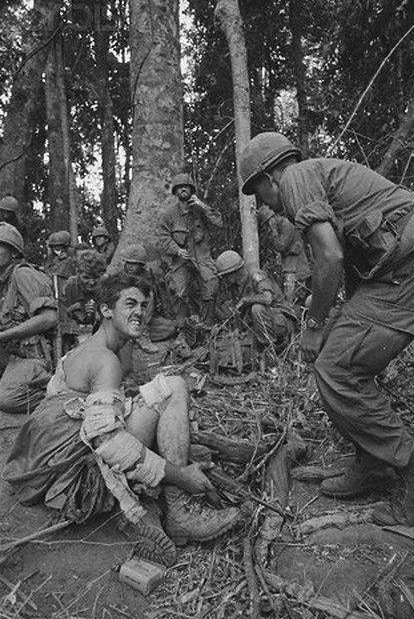

The need for protection from Viet Minh and Viet Cong traps containing "Punji" sticks (sharpened bamboo sticks two or three feet high and often dipped in dung to infect the tip, stuck into the ground at an angle so as to puncture the foot of an enemy soldier) was first recognized by the French colonial troops during the First Indochina war (1946-1954). This fact was rediscovered by American forces in the early 1960s, as the Vietnamese guerrillas still used to set their favorite time-proven "Punji" stake traps, that caused multiple foot injuries to U.S. forces. Punji tilt boards can fly up out of nowhere at a victim's face and chest.

The term "Punji" sticks itself first appeared in the 1870s, during the border conflicts in the North East Burma between the British Indian Army and the Kachins tribes, which used the sticks in their guerrilla operations and, subsequently, "enriched" the English language with this name. "Punji" sticks were deployed in the preparation of traps, ambushes or to complement various defenses. In the preparation process, the stake itself were often sharpened and, in some cases, rubbed with toxic plants or frogs, often even with feces, to cause infections in the wounded enemy.

The Americans answered with using steel plate inserts in the form of separate insoles that was slipped into the "jungle" boots. This concept was tested in 1963, and too many users developed blisters or had problems with the fit of their boots when using such slip-in protective insoles. For example, during the war in Vietnam Colin Powell, a former Chairman of the Joint Chiefs of Staff of the U.S. Armed Forces, was injured by "Punji" sticks trap. His "jungle" boots were not protected by the steel plate, and when his foot fell into the trap at an angle, and the "punji" stake just penetrated his instep, having punctured his boot out-sole entirely.

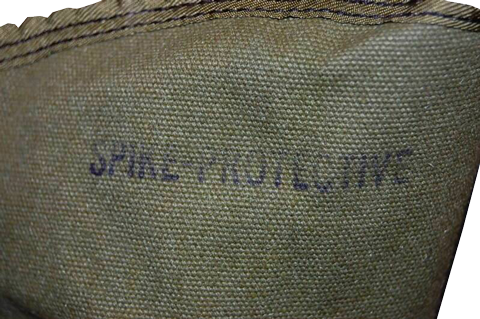

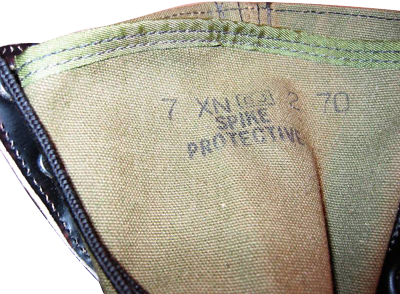

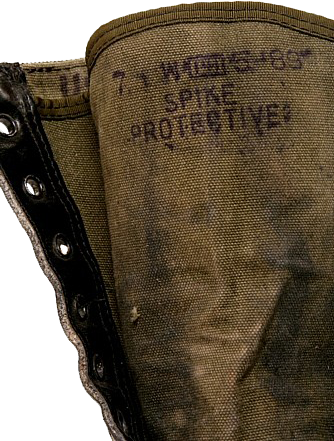

After numerous widely reported incidents of May 1966, the specification was revised, and the issue Jungle boots were fitted with a stainless steel plate inside the boot's sole (as an integral part of the sole construction) to protect the wearer by this "spike protective" feature.

So the nomenclature for such boots became "Boot, Combat, Tropical, DMS with Spike Resistant Sole Shield".

The process of changing the standard leather boots for the "jungle" boots in Vietnam was not so fast.

One should also mention that the conventional leather combat boots remained in service until the end of the Vietnam war in rear areas, or wherever the "jungle" boots were not applicable for any reason, for example for pilots and other U.S. Air Force staff, for which fire hazard precluded the use of nylon.

The U.S. Air Force personnel and some soldiers of the other units preferred to equip their "jungle" boots with attachable "zippers", which allowed quick pulling the boots on and off. Such "zippers" were designed for jungle boots and were used during the Vietnam war.

US "Jungle" Boots with "Vibram®"-type out-soles

The "jungle" boots ("Boot, Combat, Tropical, Mildew Resistant") were developed by U.S. Army Soldier Systems Center in the framework of military specification MIL-B-11431, publish date: September 6, 1951-09-06, the last revision of which is MIL-B-11431C of March 31, 1960.

The First Pattern "jungle" boots went in production circa 1962. The manufacturer's info and the date of production at that time used to be located on a white textile tag that was sewn into the tongue of the boot.

These boots featured black leather and OG107 olive green canvas upper, but they lacked the nylon ankle reinforcing band of the later patterns boots. The key peculiarities of the First Pattern boots were: leather band at the top of the boot and a leather backstay that ran from the heel to the top of the boot. These boots also featured the first DMS (Direct Molded Sole where the sole was bonded to the upper in the process of vulcanization) soles and the "Vibram®"-type tread pattern out-sole.

The Second Pattern "jungle" boots went in production a couple years later, circa mid-1965, they also featured black leather and OG107 canvas upper and DMS "Vibram®"-type soles. The improvement over the First Pattern "jungles" consisted in the change of material of the bands at top and from heel to top (the leather was changed by nylon).

The Second Pattern boots still lacked an ankle reinforcement on the sides and they also featured the same "Vibram®"-type soles as the First Pattern boots.

The Third Pattern "jungle" boots featured the same upper construction as the previous Second Pattern boots but with the addition of a nylon ankle reinforcement bands on both sides of the boots to reinforce the overall construction. At all there were two types of the out-soles: "Vibram®" and "Panama".

The Third Pattern "jungle" boots with the same "Vibram®" out-soles of the First and Second Pattern "jungle" boots were improved in 1966 with the introduction of the new Spike Protective Sole (as it was told before, this feature consisted in bonding of a stainless steel plate into the footbed of the DMS "Vibram®" out-sole).

Exclusively for cartalana.com

We have much more interesting information on this site.

Click MENU to check it out!

∎ cartalana.com© 2009-2025 ∎ mailto: cartalana@cartalana.com