Rights Reserved - Free Access.

This digital object is protected by copyright and/or related rights. This digital object is accessible without charge, but its use is subject to written permission.

Unless expressly stated otherwise in the licensing conditions, you are free to make any of the acts permitted by your national copyright and related rights act, including browsing, printing and making a copy for your own personal purposes.

All other acts of reproduction and communication to the public are subject to the licensing conditions attached to the digital object.

ARMY BOOTS OF THE WORLD. REVIEWS

Important notice: we do not sell any boots! The prices are given for information purposes only!

USA ![]()

Early U.S. "Jungle" Boots: M-42 and M-45 ("Okinawa Boots")

Before the end of WW II, the armed forces of the United States had no wide-spread specialized footwear for hot, humid and wet climate, though American troops were engaged in many campaigns in jungle terrains, which involve constant exposure not only to heat and water, mud and sand, but also to bacterial and fungal infections and hazardous insects. The standard high and low combat boots made of leather were definitely not suitable to wear in such environment nor comfortable. As no boot could possibly keep out water and still provide sufficient ventilation to the feet in hot, humid and wet environment (i.e. to be waterproof and comfortable to wear at the same time), the idea of the boots for jungles consisted in letting the ingress of water into the boots easily and permitting perspiration to drain, drying the feet while preventing the entry of mud, sand, small pebbles and insects as well.

That's why "jungle" boots have double screened vent ports in the instep for ventilation and drainage of moisture, and textile (canvas) upper to make the boots more lightweight and comfortable. So the military boots for jungle environment must be quick drying and lightweight, durable and mildew resistant, providing protection from "punji" sticks and many other jungle hazards.

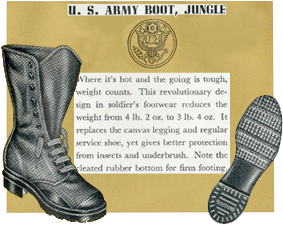

The weight of the footwear in hot and wet climate is a very important matter. Implementation of the canvas and rubber "jungle" boots instead of regular service shoes and canvas leggings allowed to reduce the weight of a pair of boots from 4 lb. 2 oz (about 1,87 kg) to 3 lb. 4 oz. (about 1,47 kg), yet providing better protection from insects and underbrush. The cleated rubber bottom provided firm footing, much better than flat out-soles of the regular service shoes.

The insoles are not less important part of the "jungle" boot concept, especially for the ones made of rubber and canvas. The famous "SARAN®" insoles were designed back in the year 1942. SARAN®" is the industrial name for PVDC (Polyvinylidene chloride), one of the first commercially available synthetic polymers, which are essentially non-irritating to the skin and are considered safe for humans and the environment. "SARAN®" insoles are made of fused layers of woven mesh PVDC, and they were used to make ventilating insoles for newly developed "jungle" boots of rubber and canvas. The "SARAN®" ventilating insoles trapped air which was circulated throughout the interior of the boot during the walking; moist interior air was exchanged for outside air via the built-in screened eyelets at the inside shank of each boot. In cold weather, the trapped air in "SARAN®" insoles kept feet from freezing by insulating them from the frozen ground; when walking, the insoles circulated moist air that would otherwise condense and freeze, causing trench foot or frostbite.

The experimental tests of the new M-1942 rubber-and-canvas "jungle" boots with "SARAN®" mesh insoles, which were made by US Army units during jungle exercises in Panama and South America clearly showed that this concept allowed to increase the flow of dry outside air to the insole and base of the foot, reducing blisters and tropical ulcers. Due to the positive results of the field tests the "SARAN®" ventilating mesh insoles were also used in the "Okinawa" boots (M-45 tropical combat boots).

The early "jungle" boots, made of rubber out-sole and canvas top, were created by US MoD in conjunction with the "US Rubber Co.". These boots used during World War II in the South Pacific Theater of operations. On August 31, 1942 the first model (M-1942 or simply M-42) was approved and went into production recently to provide the American troops fighting in the Pacific region. These boots featured canvas duck top, the tongue was stitched high to keep out water, mud, small pebbles and insects, rubber soles with corrugated tread pattern provide good traction with most surfaces. The rubber sole was kept away from the feet with removable fabric insoles, which in conjunction with cushion sole socks provided comfort of wear. In general, these boots were cool and lightweight, it was easy to dry and clean them.

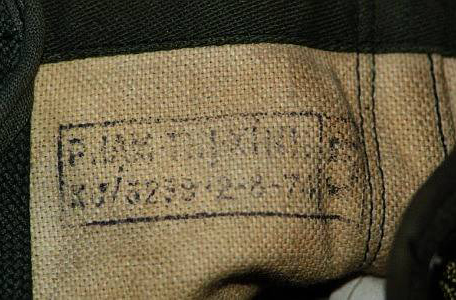

On the picture one can see green canvas and rubber "jungle" high boots are manufactured by "US Rubber Co." on September 19, 1942, that is indicated on the ink stamp inside the boots along with Contract No 155-QM-13999.

The out-soles have lug tread pattern, very similar to the "Goodyear" out-soles of the US WW II brown Mountain Boots.

As the production of "jungle" boots was not started until the end of WW II, the idea was not realized fully at that time, and all the researches in this field were suspended.

However, further on the idea of canvas boots with rubber soles was developed in other countries, from the famous original French Pataugas-type boots by Palladium, Wissart, etc. and Israeli "clones" to various North Korean, Chinese and Vietnamese versions. As it can be seen in Vietnam-issue boots like the ones shown on 15,16: they have solid rubber lug out-sole and two ventilation screened ports in the inside arch area similarly to the standard "jungle" boots of the Vietnam war times, but . The ink stamp used to be placed inside the boots. The lacing system is provided by seven pairs of simple round eyelets, and the sides are reinforced by additional stitched canvas straps.

The Armed Forces of the British Empire designed their own variant of "jungle" canvas and rubber boots, of based on the American prototype, but much higher and featuring protective patches covering the malleolus bones of the feet.

During the operations in Burma in the years 1944-1945 these boots were issued to the soldiers of Special Operations Executive Force 136. Next time these British "jungle" boots were issued to the troops during the Malayan Emergency.

However, green canvas and rubber "jungle" boots had some disadvantages. Similarly to the plimsolls and sneakers (aka "keds") these rubber and canvas boots provided little support, causing soldier's complaints of "aching arches". The high canvas tops were uncomfortable in wear, they used to chafe at the legs, so the soldiers often preferred to fold them over or just cut them off. The early "jungle" boots of canvas and rubber were overall better than the contemporary standard combat boots and service shoes in hot and humid environment, but their "lifetime" was quite short in the jungles.

There was urgent need in radical modification of those "jungle" boots, so different variants were developed and tested during at the second half of WW II. Some of them featured full-length rubber outer sole, a leather mid-sole and top of spun nylon.

There were some experimental prototypes of the boots for hot and humid climates, which combines leather and textile upper with rubber out-soles.

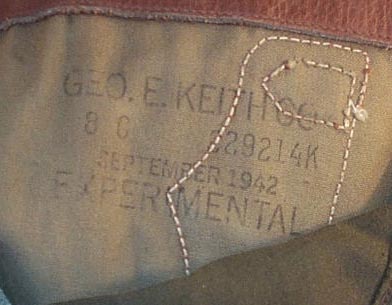

For example, the experimental jungle boots, manufactured in September 1942 by "Geo. Keith Co." featured brown leather lower and green canvas upper, lined with poplin fabric. The unlined boot's tongue was also made of green canvas and impregnated with water and/or gas repellent. The peculiarity of these boots is 3-buckle closure for a 12,5 inches (31,75 cm) tall boot. "Goodrich"-made rubber out-soles and heels were stitched and glued, and the heels were square-shaped.

Picture 1

Picture 2

Actually, the canvas and leather Tropical Combat Boots were developed in the year 1944 and put into manufacturing during the summer of the next year - too late for mass production, because the Second World war was over. Though the production was canceled, these boots were issued at the early stage of the war in Vietnam, and continued to be issued until the year 1965, when new types of DMS jungle boots with Vibram-type out-soles came into service. The brown leather and green canvas boots shown on the Picture 1 were made in June, 1950. The two-buckle fasteners on the upper part of the boots were exactly "borrowed" from the two-buckle M-43 all-leather American WW II Combat boots (Picture 2).

These double buckle "jungle" boots with brown leather and canvas panels for tropical climates are also referred to as "M-45 Tropical Combat Boots" or "Okinawa boots", because in the early years of Indochina conflict many American advisors were sent to Vietnam from U.S. military base in Okinawa, Japan.

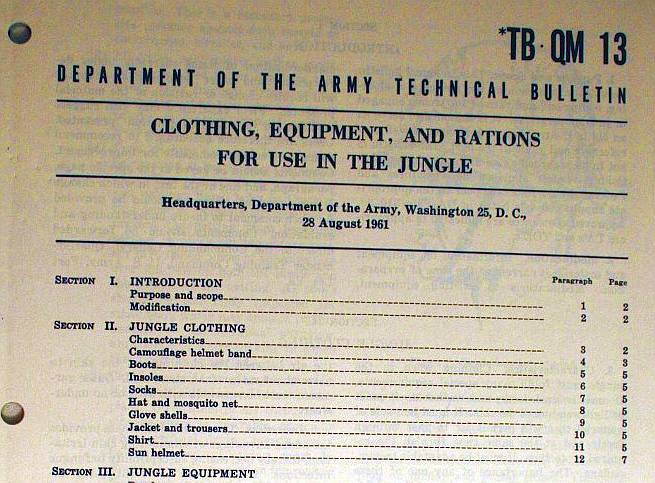

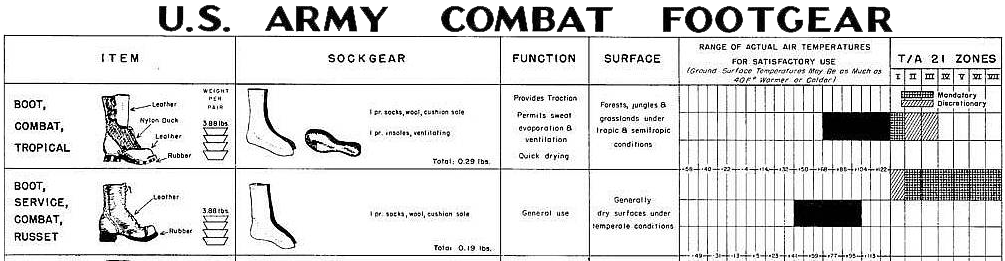

The early jungle boots are specified is such documents as US Army boot chart (1951) and

TB QM 13 (Department of the Army Technical Bulletin (Quartermaster Manual)) of 28 August 1961.

The boot chart of the year 1951 specifies "Boot, Combat, Tropical" made of leather, nylon duck and rubber, weight per pair is 3,88 lbs (1,76 kg), which are to be worn with 1 pair of socks (wool, cushion sole) and 1 pair of ventilating insoles (total weight 0,29 lbs (132 g)).

These "jungle" boots (quick-drying, permitting sweat evaporation and ventilation and providing good traction with surfaces) were designated for forests, jungles and grasslands under tropic and semi-tropic conditions.

The leather parts of the boot's top were intended to provide robustness of construction and tight grip of the legs in boots. As the leather is more thick and rigid in comparison with soft and thin canvas, it provides better protection from insects, pebbles and other hard and sharp objects that could potentially injure the feet. The canvas panels are intended to provide better temperature and humidity regulation of the feet inside the boots, and to make the overall construction more lightweight and easy to dry.

The tread pattern of the out-soles was various: from the most common lug sole design to the "Aigle"-type pattern of small round lugs resembling the hobnailed out-soles of American Model 1917 "Pershing" boots of WW I.

The identification information (such as date of production: April 4, 1952; NYQMPA (New York Quartermaster Procurement Agency) etc.) was hot-press stamped on the inner leather side of the 2-buckle fastener.

Finally, let's provide the quote from the Department of the Army TB QM 13 (Technical Bulletin Quartermaster Manual) of 28 August 1961:

"Tropical combat boots have nylon tops, leather over the toe and heel portions of the uppers, and cleated rubber soles. They protect the feet against insects, mud, rough ground, and undergrowth. The cleated rubber soles are flexible, yet thick enough to protect the feet from stone bruises or other foot injury. They help prevent slipping on muddy and grassy slopes. The boots have built-in screened eyelets, one at the inside shank of each boot. These eyelets permit air to reach the feet and allow water to drain out.

a. Fit. Tropical combat boots come in whole and half sizes and in widths ranging from extra-narrow to extra-wide. For proper feet, the boots should be longer and wider than normal footwear to allow the usual swelling of the feet in hot weather and to accommodate the ventilating insoles worn with them.

Note. Some temporary discomfort may be experienced when a change is made to tropical combat boots. This discomfort is caused by fatigue of the foot muscles. It is neither serious nor injurious.

b. Wear.

(1) The boots should be worn with one pair of wool cushion-sole socks and one pair of ventilating insoles. Additional socks may cramp the feet and interfere with proper blood circulation.

(2) The boots should be pulled on and the heel seated firmly into place. The boots should fit snugly but not tightly with the cuff buckled and the laces securely tied.

(3) Socks should be changed at least once a day; more often if necessary. The feet should be dried and massaged whenever socks are changed. This practice is necessary to prevent jungle rot.

Note. The term "jungle rot" applies to any of a number of infections that occur when the skin remains warm, wet and chafed over a period of time. Such skin conditions frequently cause casualties and require months of medical treatment and convalescence.

(4) The ventilating insoles should be removed and replaced whenever socks are changed. They may be washed and dried for future use.

(5) The insides of the boots should be carefully inspected and cleaned before boots are put on in insect-infested areas.

c. Care. The service life of boots can be prolonged by proper care. They should be washed frequently and dried in the shade or dim sunlight. They should be inspected frequently for damage from any source and turned in for repair as needed. Mud or excessive dust should be brushed off when washing is not practicable. Wax shoe polish should be applied if the leather is dry. The insides of the boots should be wiped with a moist soapy cloth, whenever possible, and air dried.

Note. Boots should never be stored or put aside when they are muddy or wet. Wet or muddy boots should never be placed near direct or intense heat.

6. Insoles. Insoles keep the feet cool, ventilated, and out of contact with rubber soles of the boots.

The insoles, which are made of several layers of plastic material woven like screen wire, are not affected by perspiration or mildew. They allow air to reach the soles of the feet and thereby provide insulation against ground heat. They should be washed in warm (not boiling) soapy water and dried in dim sunlight or any place away from intense heat.

7. Socks. The stretch-type wool socks with cushion soles have a tufted knit construction to provide extra cushioning for the feet. This extra cushioning not only absorbs perspiration from the soles of the feet, but provides additional insulation as well. The socks are issued in three sizes, and close attention must be given to proper fitting in relation to boots and ventilated insoles. Socks that are too large will wrinkle, rub the feet, and cause corns or blisters. Socks that are too small may cramp the feet and will wear out the toes. Socks should be washed regularly in lukewarm water with a mild soap, then rinsed thoroughly in clear water to remove all traces of soap. They should be stretched into shape while drying.

Exclusively for cartalana.com

We have much more interesting information on this site.

Click MENU to check it out!

∎ cartalana.com© 2009-2025 ∎ mailto: cartalana@cartalana.com