Rights Reserved - Free Access.

This digital object is protected by copyright and/or related rights. This digital object is accessible without charge, but its use is subject to written permission.

Unless expressly stated otherwise in the licensing conditions, you are free to make any of the acts permitted by your national copyright and related rights act, including browsing, printing and making a copy for your own personal purposes.

All other acts of reproduction and communication to the public are subject to the licensing conditions attached to the digital object.

ARMY BOOTS OF THE WORLD. REVIEWS

Important notice: we do not sell any boots! The prices are given for information purposes only!

Holland ![]()

Dutch Military Boots of Models M/57

The armed forces of the Kingdom of the Netherlands ("lower lands") consists of three arms: the Royal Air Force (Koninklijke Luchtmacht - KLu), the Royal Army (Koninklijke Landmacht - KL) and the Navy (Koninklijke Marine - KM). The Royal Marine Corps (Korps Mariniers) is operatively subordinated to the Netherland's Navy.

In addition, under the auspices of the Netherlands Navy there are the Royal Military Police (Koninklijke Marechaussee - KMar) and a small contingent of recruited troops in the Caribbean: Aruba (Arumil) and Curacao (Antmil).

The Netherlands Antilles (Nederlandse Antillen) are in the Caribbean region. Since December 15th, 1954, this territory is self-governing, and on October 10, 2010 the Netherlands Antilles actually moved from state entities, which were a part of the Netherlands and became the separate self-governing territories of the Kingdom. Since the 1990s, the Dutch troops took part in the four major military campaigns in: Bosnia, Kosovo, Iraq and Afghanistan (Uruzgan Province).

Currently, the Minister of Defence of the Netherlands is female, her name is Jeanine Hennis-Plasschaert.

In the late 1950s, the armed forces of the Netherlands began to use brown military boots of the models M/57.

In fact, these boots were just a simplified version of the American "jump boots" of the 1940s. At first, they were provided to the paratrooper units, then - to the rest of the army, as well as it used to be in the United States.

The "jump boots" represent by themselves the high-lacing rubber-soled leather boots, intended to provide extra ankle support when landing by parachute. Such boots were issued to the paratroopers since the August 3, 1942, when the final model was approved by the specification of Boston Quartermaster Depot (BQD No. 58D). Although jump boots were to be replaced by the new type combat boots, they still continued to be worn throughout the war and even nowadays.

The first American "jump boots" were designed in 1941 by William P. Yarborough, and got the nickname "Corcorans" by the name of Corcoran®/Matterhorn® Company, a division of Cove Boot Company, located in Martinsburg-city, Pennsylvania. This Compamy was the first US Department of Defense contractor to manufacture these boots.

Almost from the very beginning, the "Corcoran" jump boots have become the symbol of elite status footwear for Rangers and paratroopers not only in the US, but almost all over the world. These boots are still manufactured, and very certain special forces and airborne soldiers are officially authorized to wear "Corcoran" boots with their dress uniforms as a sign of high qualification and merits.

The Dutch army boots model M/57 are practically compliant with the American specification for the russet-coloured chrome leather army boots, created in the year 1948 - the so-called "M1948 Boots, Service, Combat, Russet".

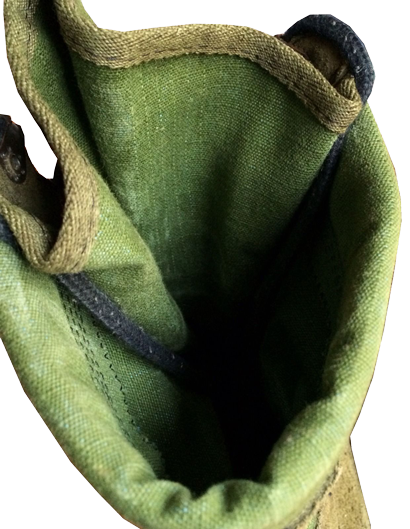

The boots M/57, as well as the American prototypes, are red-brown ("russet") in color, they differ with the reinforced toe and counter (extra layers of leather). On the inside of the boot's top there an additional suede strip is sewn down in order to keep the pants tucked in the boots and for more tight fit. The leather upper is processed by "shagreen" technology and was supposed to fat impregnation. The sole of the boot is made of thick cowhide with sewn and glued rubber tread.

So, if the Dutch M/57 boots are just a copy of the American boots, let's make a short historical tour.

In the previous years, the out-soles of the military boots were made of thick cowhide, but circa 1940 the US military began developing combat boots with rubber tread pattern. Soon the decision about the economy of scarce raw materials, which were used for production of high-quality boots, was made, and wide use of different alternative materials began. The resulting effect (serious drop in quality of the boots) was so strong that the US Armed Forces hastily abandoned the substandard substitutes by middle of 1942.

The previously used low boots with gaiters were extremely unpopular among the troops, because gaiters poorly fixed the ankles, they were inconvenient in use because the side lacing, the process of putting on and off the gaiters and low boots was long and uncomfortable, so a lot of complaints from the soldiers were received. Therefore, the further transition to high boots became simply inevitable.

The original American boots, taken as an example to be copied, were as follows:

From 1956 to the 1970s these boots were issued in the black colour. The out-soles of the model M/57 Dutch boot, like the American ones, were reinforced with boots nails on the perimeter of the heel. The tread pattern is typical for the American army footwear - the ribbed shallow "grid". The in-depth holes were provided on the rubber heel for tamping nails.

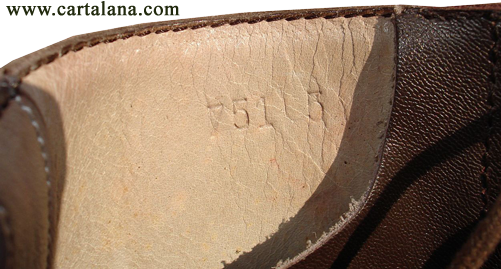

Lacing system consisted of eleven pairs of round bronze eyelets. The flap of the boots tongue is semi-closed. The marking with the serial number and date of manufacture was applied by hot stamping on the outside of the upper side of the boots.

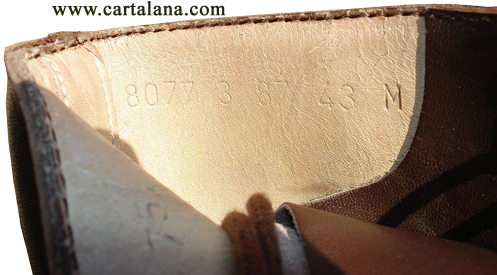

Actually, the Netherlands' military boots of the model M/57 can be distinguished from the American military boots only by the marking on the sole and the leather top. In the photo shown below one can see the marking of KL (Koninklijke Landmacht) - i.e. The Netherland's Army and the size, and soles and heels show "Indiana" - the logo of the manufacturer. "Indiana" is a Dutch company from Lelystad (Lelystad), which manufactures rubber soles even nowadays.

Since September 1, 1956 the US forces made transition from brown-coloured boots to the black-coloured ones, while the other characteristics of the "M1948 Russet Combat Boots" model boots remained unchanged. There you can see the photo showing the boots repainted from brown to the regulation-defined black colour by the soldiers themselves.

At the top of the boot shaft the "hot stamping" marking is specified. On the inside shaft the size and fullness of the boots are indicated (the picture shows size 43 and "B" ("Breed") width - i.e. for wide feet. On the outside shaft the 4-digit military identification serial number (in this case 8800) and the date of manufacture this pair of boots - the month and the year of production (1-67, i.e. January 1967) are indicated in the round-shape stamps.

Military Boots of the Netherlands - Model M/66

In the mid-late 1960s the Armed Forces of the Netherlands introduced military boots model M/66, which were used until the year 1990. These boots were russet-brown in colour, traditional for many European armies in the 1960s-70s. Since the 1980s, these boots were also supplied in black colour.

The design of these boots was "borrowed" from American "safety boots", mainly produced by "Addison Shoe Company", a Division of NMF Inc., located in Wynn, Arkansas. "Safety boots" are widely used by the US Air Force and the Navy. The design of the boots, still widely used nowadays features minimum stitched joints of the leather top, thus increasing general robustness and water resistance, especially if the boots are treated with quality boot polish.

The top of these boots is made of hard durable hydrophobic grained leather, treated by the "pebbling" method. The leather lining inside the boot is made of soft and durable "glove-type leather" of light yellow or grey colour.

The Dutch army slang names for their military boots are "Legerkisten" or "Legerlaarzen" - "military chests" and "military boxes" correspondingly. In this matter the Dutch are similar to the Germans, which for decades (until the early 1970s) used to wear army high boots called "Knobelbecher".

On the German soldiers' slang the word "Knobelbecher" means "dice cup", because these sturdy high boots were made of very thick and rigid leather, so the soldier's feet used to be clattering inside the boots very similar to the dice in a cup.

The out-sole is made of solid vulcanized rubber. These boots are made by DMS (Direct Moulded Sole) method, which is progressive and modern even today, as opposite to conventional "glue-and stitching" method.

| Matentabel Kisten KL: |

| 220=35 225=36 230=37 235=37.5 240=38 245=38.5 250=39 255=40 260=41 265=42 270=43 275=43.5 280=44 285=44.5 290=45 295=46 300=47 305=47.5 310=48 315=49 |

DMS-type boots are manufactured on fairly expensive equipment, because the boots of each size are made on separate machine tooling unit.

The US armed forces have moved to the "DMS" method of boots manufacturing back in the 1960s, abandoning the methods of "glueing" and "glueing-and-stitching".

The tread pattern of the M/66 boots soles resembles the "Tractor"-type tread of the American "Firestone" jeeps of the World War II times

The boots tread pattern was presumably created on the basis of the German paratroopers boots out-soles, which were introduced in the Third Reich's Luftwaffe back in the 1930s. This protector provides excellent adhesion to most surfaces and has the property of "self-cleaning". Such a tread pattern has long been used on the model M60 boots of the Armed Forces of Czechoslovakia as well.

The "speed lacing" system, which greatly facilitates pulling the boots on and off, features 7 pairs of bronze eyelets, manufactured by "MARK" company

The flap of the boots tongue is "closed", like on all the other army boots. The tongue is stitched to the boot's top in order to protect the feet from penetration of dust and pebbles and from the ingress of water inside the boots. One can safely come into the water safely up to the level of the sixth pair of eyelets (counting upward).

The military ID-markings on the M/66 model boots is placed on the out-sole.

For example, the marking 43M means size 43, M = Middel (Middle) widths; below the size and widths are repeated in the "Mondopoint" system (in mm) - 274/97. Below the national markings "NL" (the Netherlands) is indicated. The Identification serial number and the month/year of production are marked inside the boots top.

Dutch "Desert" Boots Model M92

The military boots of the Netherlands (model M90) has become the basis for development of the first test model of the "desert" boots. It represented by itself almost complete analogue of the M90 Dutch boots design, up to the D-shaped laces fixing loop on the padded tongue. Lacing system is just a copy of the Dutch M90 army boots: the lower two pairs of simple round eyelets, above - hook clamp for laces fixation, and five pairs of speed-lacing "MARK" eyelets in the upper part. The flap of the boot's tongue is semi-closed.

The out-look appearance of these boots was characterized by: sand-coloured suede top (leather cushioning on top of the boot is made from smooth leather); the top was glued and stitched to the out-sole; the lightweight yellow-coloured "VIBRAM" polyurethane out-soles with a standard tread pattern, patented back in 1937 by the Italian inventor VItale BRAMani. A small batch of such boots was manufactured for testing under real desert conditions.

However, the tests in the real heat of the desert revealed significant shortcomings - these boots were very hot, and poor air ventilation caused discomfort feelings when worn. The leather cushioning at the top of the boots used to overlap the in-flow of air, although it protected well from sand and small pebbles. After summarizing tests reviews, on the basis of the same model M90 Dutch military boots, in 1992 a new M92 model "desert" boots was developed. By their design M92 boots were more similar to the American "desert" boots. The Dutch name for these boots is: "GEVECHTLAARS DESERT M92".

The leather cushioning on top, like the upper part of the boots was replaced by lightweight and much more breathable canvas. Below the canvas part of the boots top came suede elements, which proved to be excellent in hot, dry desert climate. The suede of light sandy colour is heated by the sun much less than black smooth leather. Suede is a breathable material, which does not require any special care, and at the same time it is sufficiently strong and scratch-resistant. For waterproofing of the boots surface it is recommended to treat the suede with any "AQUASTOP" spray.

The out-sole and the tread pattern became a little different: the early boots feature more solid and dense out-soles with groove on the heel. The tread pattern itself was more simpler - as it can be seen on the following photo:

Later model boots were made of more soft material, without groove on the heel, while the tread pattern became more complicated:

The marking of the out-soles usually indicates the size in the "Mondopoint" system, the military ID code and the width of the boots - S, M or B. According to the Dutch army classification these letters respectively denote the width (completeness):

- S = Smal (narrow);

- M = Middel (middle);

- B = Breed (wide).

The lacing system, depending on the manufacturer and year of production could be different:

- with full speed-lacing system of 8 pairs of round eyelets;

- with lower two pairs of simple round eyelets and upper six pairs of speed- lacing eyelets;

- with lower four pairs of round eyelets and upper three pairs of speed-lacing eyelets.

The flap of the boot's tongue is "closed", i.e. Stitched to the top of the boot.

These boots have been widely used by military personnel of the Netherlands during the operations in Iraq and Afghanistan.

Dutch Green Summer Boots (a Version of M92 "Desert" Boots)

Green suede summer boots of the Armed Forces of the Netherlands ("Zomer kist groen" in the Dutch language) are very similar to the "desert" boots model M92, and in common parlance is often mistakenly referred to as "jungle" boots ("Jungle kist") even among the Dutch customers themselves.

Of course, these are classic boots for dry and hot climate, and it would be foolish to wear them in the tropical rainforests, because they are made of suede and they feature no drainage holes for excessive water output. Moreover, the tread pattern of such boots should lead to a rapid build-up of dirt. The real "jungle" boots should have self-cleaning tread pattern like the famous American "Panama" sole, which have been developed during the times of war in Vietnam and tested in the jungles of Panama.

The need in development of these boots was caused by virtually the same reasons as the emergence of the Swedish green summer "Peter Pan boots". These boots were made for the Dutch soldiers who participated in the UN and NATO operations in the former Yugoslavia (Bosnia), and during the development of these boots the local Balkan climate and the predominant green vegetation was taken into account. Further on, these boots have been used in Afghanistan, at the early stage of operations. According to colour shades of suede, these boots could have colour hues from bright green to olive-brown, especially if they have long been exposed to the direct sunlight and covered with dust.

The detailed examination of the structure and materials of these green summer boots shows their deep similarity to the M92 "desert" boots of the Netherlands, starting from Direct Moulded Sole (DMS) method of out-sole attaching and up to the lacing system, which could also vary from the early version with full "speed-lacing" system to the version with two lower pairs of simple round eyelets instead of "speed-lacing" eyelets.

Dutch military boots for summer were also available in black colour. These models were provided to the police forces. Such boots featured full "speed-lacing" system. The marking with size and widths was indicated on the out-soles of the Dutch summer boots.

The material of the later nitrile rubber out-soles, used for the Dutch green summer boots, over time reveals a tendency to cracking and self-destruction. Another important drawback of these boots - according to my personal customer's feelings these green summer boots of the Netherlands are not very comfortable to wear, because the in-seams of the boot's top stitching are quite crude and can rub, especially when the size and width of these boots are chosen not correctly.

"Jungle" Boots of the Netherlands, Model M93

The first model of Dutch boots for hot and humid climate (1970-80s) is actually a hybrid of early American and British "jungle" boots.

The lacing system consists of 10 pairs of simple round eyelets (4 lower and 6 upper pairs), between which there was a cut-out for better flexibility of bending). The boot's top consists of green tarpaulin (the Dutch themselves use the term "canvas" to call this material) and black grained leather. The out- sole is made of rigid polyurethane (the material resembling German jungle boots by "Baltes" company), the tread pattern of the out-soles were of own Dutch design, similar to the British "jungle" boots.

Since the 1990s, the Dutch troops took part in the four major military campaigns in Bosnia, Kosovo, Iraq and Afghanistan (Uruzgan Province).

In 1993, in order to provide the troops with more advanced boots for hot and humid climate, the Dutch Ministry of Defence developed the boots of model M93. The name used for these boots in the Armed Forces of the Netherlands is "M93 KL jungle, tropen legerkisten" (model M93 military boots for jungle/tropics of the (Dutch) Royal Land Forces).

Just as in the case of model M92 "desert" boots , it can be seen that the early model of Dutch "jungle" boots feature hard rubber out-sole (with a longitudinal groove on the heel),

and the tread pattern of the out-soles is somewhat simpler than that of a later version of the out-sole, which was made of nitrile rubber (the heel had no groove).

This new model of the Dutch "jungle" boots represented by itself a hybrid model of M90 boots and the early summer green suede boots, which were created on the basis of model M92 boots. In fact, these boots practically the same, with the exception of top: green suede was replaced by a sleek black hydrophobic leather treated by the method of "pebbling", that gives the leather a slightly "grainy look" and improves elasticity. The lacing system and the out-sole tread pattern are the same.

As it was described before, the out-soles of the early boot were made of hard rubber, with a groove on the heel, while later models had groove-less heel and softer out-sole of nitrile rubber, and the tread pattern of the late boots had a little more complex figure.

The next step in the development of Dutch boot for hot and humid climate was made by "HAIX" footwear company, which supplied the Armed Forces of the Netherlands with a hybrid model, which represented by itself a lightweight version of "HAIX" Modell 2005/2007 boots and the latest model of the Dutch "jungle" boots, with the addition of some elements, inherent to "tropical" boots by "Baltes".

The "origin" of these boots essential elements:

- From "HAIX" this model "got" the standard out-sole with tread pattern, typical for this company's products;

- From Dutch "jungle" boots this model "borrowed" the standard canvas top, the same as on the green summer boots;

- A pair of conventional ventilation and drainage eyelets on each boot, the design of the counter as well as the leather band with a loop for laces fastening on the back side of the top are similar to the "Baltes" boots features:

The lacing system has been modified: three pairs of simple round eyelets in the lower part, a pair of hook-clamps to fix the lacing above them, and four pairs of D-shaped loops (to perform the function of speed lacing system) in the upper part of lacing.

It was the "HAIX" company, which also manufactured green and black suede boots (a version of the model described above) for the Dutch army. The only difference between these types of boots consist in the material used: smooth black leather was just replaced with suede. The lacing system remained the same, as well as the out-sole - the customers will easily recognize the out-sole of full leather Bundeswehr boots Modell 2005/2007.

Sources of the information and images:

http://armyworld.pl

http://atthefrontshop.com

http://bataindustrials.com

http://cdn.choosehelp.com

http://corcoranandmatterhorn.com

http://defensie.nl

http://dumponline.nl

http://dumpstorehengelo.nl

http://eearmystore.net

http://flagchart.net

http://gerba.nl

http://lavoroeurope.com

http://marktplaats.nl

http://mygasmaskcollection.blogspot.com

http://olive-drab.com

http://soldiersystems.net/blog1

http://surplusandoutdoors.com

https://benscore.com

https://benscore.com

https://etsy.com

https://s-media-cache-ak0.pinimg.com

Exclusively for cartalana.com

We have much more interesting information on this site.

Click MENU to check it out!

∎ cartalana.com© 2009-2025 ∎ mailto: cartalana@cartalana.com