Rights Reserved - Free Access.

This digital object is protected by copyright and/or related rights. This digital object is accessible without charge, but its use is subject to written permission.

Unless expressly stated otherwise in the licensing conditions, you are free to make any of the acts permitted by your national copyright and related rights act, including browsing, printing and making a copy for your own personal purposes.

All other acts of reproduction and communication to the public are subject to the licensing conditions attached to the digital object.

ARMY BOOTS OF THE WORLD. REVIEWS

Important notice: we do not sell any boots! The prices are given for information purposes only!

Holland ![]()

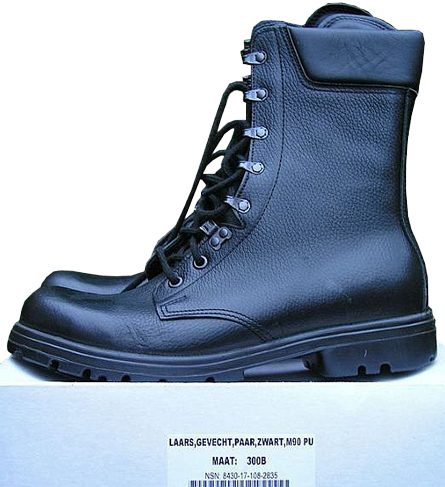

Military Boots of the Netherlands - Model M90 (M400)

In the mid-1990s the Dutch Armed Forces transferred from the model M66 army boots (brown and black) to model M90 black boots (the so-called "Militaire Legerkisten M90 Landmacht Model"), developed by "Bata Industrials" and adopted in the year 1990.

It is worth mentioning, that these model M90 boots are also called model M400 - this is just an internal development code of the manufacturer, and can be found mainly on the dedicated Dutch-language forums and web-sites. In such a way these boots got double identification name, used by military and manufacturers. The name M90 is used much more.

As it was mentioned in the other military boots reviews of the present series (dedicated to the Dutch and German military footwear), the Dutch themselves colloquially use the following slang words to call their army boots: "Legerkisten", "Legerlaarzen" ("army chests", "war chests") and "Legerschoenen "("military boots"). Sometimes these words combinations in the title include the word "Gevechts" ("Combat"), so we can see, for example, the name "Gevechtslaars".

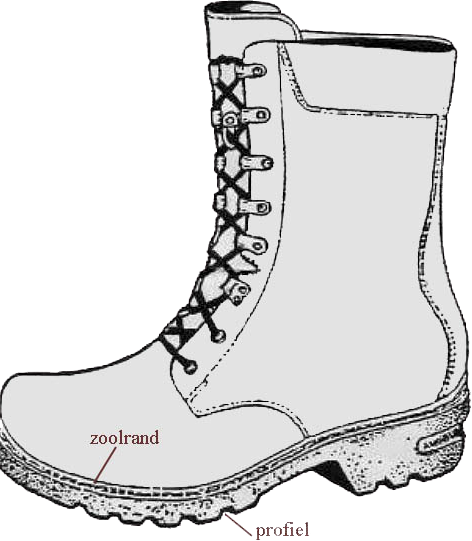

The most characteristic features of M90 boots, as compared with the model M66, are the improved design and overall construction, which became closer to the anatomically correct shape; the out-sole is made of double-layer nitrile rubber; a wide soft cushion on the top edge of the boots was added, as well as padded tongue and grey-coloured "glove"-leather lining inside the boots - all these novelties give very comfortable feeling when worn.

Speed lacing system of seven pairs of eyelets has been replaced by five pairs of speed lacing eyelets at the top, hook-clamp for laces below and two lower pairs of simple round eyelets. The soft padded tongues of these boots feature "D"-shaped rings to fix lacing.

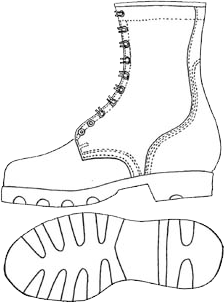

At that time almost the same transformation occurred with the standard US army "Mildew-Resistant Speed-Lace" boots. The early versions of these boots featured full-scale quick-lacing system, consisting of ten pairs of cylindrical eyelets. Since 1994, due to the uselessness, the low-most two pairs of cylindrical eyelets were replaced with simple round eyelets

The new M90 boots are supplied with new type insole, consisting of a special three-layer material (cloth) "Saran", that provide temperature and humidity regulation inside the boots due to air cushion. This "Saran" insole has anti-fungal and shock-absorbing properties as well.

M90 boots are black-coloured only, they are made of soft and flexible hydrophobic leather, they feature DMS (direct-moulded soles), as well as the previous M66 model. The toe and the counter are protected with plastic "toe-cap" and the plate accordingly.

Among the major developers and manufacturers of the Dutch army boots one should mention three companies:

"Bata Industrials",

"Bata Industrials",

"Gerba B.V." (the other variants of this name "Gerba - NL", "Gerba - Windsor legerschoenen" can be also found) and

"Gerba B.V." (the other variants of this name "Gerba - NL", "Gerba - Windsor legerschoenen" can be also found) and  "Lavoro".

"Lavoro".

The first company of this list is the largest manufacturer and supplier of military footwear not only for the Armed Forces of the Netherlands, but for the other countries too. For example, the company's boots were supplied to the US Army during the Vietnam War and until the end of the 1980s.

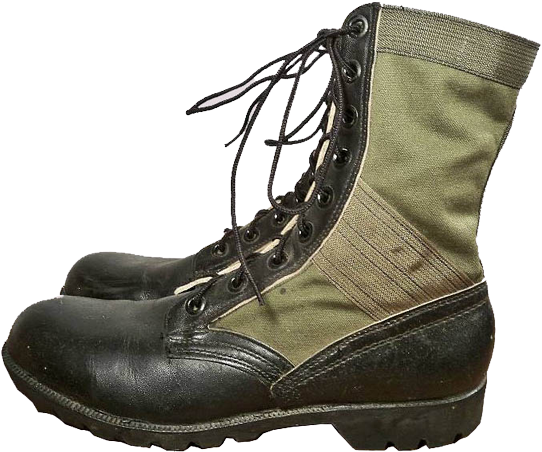

"Bata" has been supplying the American troops with the famous "jungle" boots: the early models featured "Vibram" out-soles (the presented photo shows the appearance of the out-soles, produced in 1967);

next models came with the "Panama"-type out-soles (the photo shows the out-soles produced in 1988). One can see the italic inscription of "Bata" logo.

Thomas Bata, who founded "Bata Industrials" footwear company in 1894, began production of boots in Zlin (Czechoslovakia). Further on the talents and efforts of Thomas Bata turned the company into one of the leading enterprises in Europe.

After the successful start of footwear production in Czechoslovakia, Bata decided to build his factories in other countries, including the Netherlands.

In 1922, the first boot shop "Bata" was opened in Amsterdam. Unfortunately, on July 12, 1932 the company's founder lost his life in the plane crash nearby his industrial complex. His son, Thomas Bata Jr., inherited the family business and founded "Bata Shoe Organisation" holding.

"Bata" has acquired a plot of land in the municipality of Best town to build an industrial complex and Batadorp (Bata Village in Dutch), which was the exact copy of the company's headquarters buildings in Zlin.

The policy of the company owners to their workers was notable for care and humanity, that was not so usual in those years. In particular, the company built Batadorp village near the plant (allowing the workers to get to their workplaces easily) and took care of the worker's spare time. There were built about 130 houses and a private school, medical centre, football and tennis clubs ... These houses can be seen even today, they distinguish from the other buildings with characteristic flat roofs.

Later the town of Best became the main production centre. But in the early years Batadorp village was separated from Best due to lack of a bridge over the Wilhelmina Canal. The location of manufacturing facilities in the province of Brabant, where the town of Best was located, was chosen due to the presence of accessible and inexpensive labour resources and because of good location: in the proximity there were the railway junction at Eindhoven and intersection of Wilhelmina Canal and Beatrice Canal.

In 1933 the production of rubber soles began, and a year later a wide range of footwear for men, women, children, athletes began to enter the market, including different kinds of footwear from rubber - from slippers to rubber boots.

The manufacturer keeps silence about the period of the Second World War. But one can assume surely that the Dutch and the Czech manufacturing facilities used to supply Wehrmacht (the Armed Forces of the Third Reich) with the produced footwear.

In the 1960s the standard of living and wages in the West Europe increased significantly, so the labour-intensive production facilities had to be moved out, somewhere to the countries with cheaper labour force. During the Vietnam War, "Bata" used to produce "jungle boots" under the contract with the US Department of Defence.

In the late 1970s there has been a specialization of the company in the production of labour and occupational footwear ("safety boots") and socks. In the future, the transition in orientation from ordinary customers to the massive orders from the industry was increasing definitely.

By this time "Bata" company had no longer any need to maintain a large industrial complex, because robotic production has been implementing increasingly. So in 1978 the municipality of Best sold the unused land and buildings, and the Batadorp village itself too. Even the name "Batadorp" disappeared. In the same year the "Bata Nederland BV" company, a subsidiary of "Bata Ltd.", located in Eindhoven, began to manufacture and sell its products in retail.

In the 1980s, under the contract with the Ministry of Defence of the Netherlands, "Bata" has developed a new type of army boots (model M90) and produced the first 90 thousand pairs of boots.

On today "Bata Industrials", as a part of the "Bata Shoe Organisation" association, is a leader in the Benelux countries. It has the manufacturing facilities in various countries around the world. The company's amount of products is from 50 to 100 million US dollars (including up to one million pairs of professional boots and up to 700 thousand pairs of socks), about half of the production is exported.

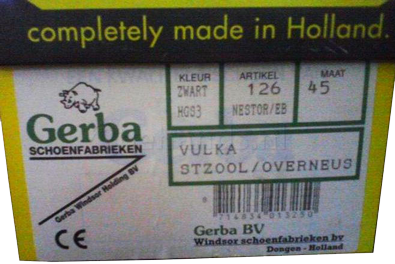

The company "Gerba B.V." ("Gerba-NL") is located in the Dutch city of Dongen (Hoge Ham 123, Dongen, 5104 Netherlands), was later transformed into a company "Gerba Schoenenfabriken" ("Gerba Windsor Holding BV"). According to the information from the Internet, the company declared bankruptcy on June 20, 2006.

The company "Gerba Shoes BV" (Edisonstraat 6, Goirle, 5051 DS, Nederland), which is still present on the market of professional and occupational footwear, had focused on more profitable market of "safety boots", i.e. the footwear that is certified to European safety standard for occupational footwear - CE EN ISO 20345. By the contract with the Dutch Ministry of Defence, the modified version of the standard M90 combat boots have been delivered as working boots to the Armed Forces.

One can see the following marking (according to EN ISO 20345) on such boots:

- S1 - fully protected areas of the heel and the toe (with steel plates), anti-static and shock-absorbing soles);

- S2 - the same as S1 + waterproof upper;

- S3 - the same as S2 + intermediate protective steel plate in the sole, or "Kevlar" insole;

- S3 - T, a variation S3, plus an extra pad on the toe;

- O2 - compliance with the essential requirements of the standard, including waterproof upper, but without the steel plate in the toe.

In the Dutch Armed Forces there are also used the boots, similar to the model M90-M400 (type S3), but certified in accordance with EN ISO 20345 safety requirements and produced by "Lavoro", a Portuguese company.

The word "LAVORO" is the Portuguese acronym formed from the first letters of the words denoting the corporate values:

L = Luso (word for commitment to the Portuguese identity);

A = Activo (activity);

V = Verdade (true);

O = Ousadia (confidence);

R = Responsabilidade (liability);

O = Ordem (order).

Certain modifications (e.g., model M11) can be fitted with standard lacing system (top five pairs of bronze "MARK"-made eyelets of quick lacing system, a pair of hook clamps to fix the lacing and two pairs of simple round eyelets at the bottom).

The other versions in their design have no metal at all (100% of metal parts are replaced with plastic, and the usual round eyelets are used instead of speed lacing system).

The standard metal detectors, which are used to ensure security at airports and other facilities just don't react on such boots. The lining of such boots is standard for the new versions boots it is made of soft leather with insulation. The sole is not standard military one, but it is close to "sports shoes" type, being equipped with "Clima Cork", a climate control support system. The available sizes of such boots are from 35 to 47 in European metric.

Some batches of such boots can be supplied from "Lavoro" plants, located in Italy.

All the M90 boots, depending on the manufacturer and the destination, have small differences in the shape of the sole and the heel, and the tread pattern as well.

The Netherlands marines used a type of boots featuring longitudinal grooves on the heels, with the soles made of solid vulcanized rubber. The boots without such grooves, but with softer out-soles of nitrile rubber, have been delivered to the ordinary army units. The tread patterns of both types out- soles were also different.

According to my subjective user experience, the Dutch combat boots of M90 model are very convenient and comfortable to wear, they fit perfectly the feet and they don't rub, if the size is selected properly.

The size and fullness of these boots are specified on the out-sole in the European metric and in the "Mondopoint" system, while the size and the serial ID-number of the boots are duplicated on the inner side of the tongue.

The Dutch "Marines'" version of the M90 boot is more robust and reliable. For the ordinary military boots (with smooth surface of the heel), the disadvantage of cracking and fracture of the out-sole material are shown eventually. The reason for this consists in the properties of the nitrile rubber: it is prone to drying out and the components of its double-layer structure has different density, so, with all the conveniences of such out-soles, they are relatively short-lived. Due to the ingress of water into micro-cracks the structure of the out-sole gets wet, the process of hydrolysis begins, and the our-soles just start crumble from inside. In contrast, the old M66 model boots served a lot better and were more robust and reliable, yet more rigid and less soft in comparison with the new M90 model.

Trying to solve the problem of the out-soles destruction, "Gerba" company used to equip M90 model boots with other out-soles made of solid vulcanized rubber, with the same tread pattern as the French "Rangers" boots.

So they managed to create quite robust and comfortable boots, having combining the advantages of the out-soles, proven by decades of hard service, and the new leather upper, which is more advanced technologically.

The globalization trends didn't pass round the NATO armies. One of the intermediate models of the Dutch army boots was created on the basis of the M90 model, but with the disastrous out-soles like on the Bundeswehr "Model 2000" boots, virtually indistinguishable from that of the Belgian model, as I have mentioned in the review, dedicated to the Belgian military boots on the same site: www.cartalana.com.

Sometimes the "Dutch" and the "Belgian" models of the boots are even confused during forums discussions. To clarify this issue, let's notice, that the Belgian boots feature three pairs of round eyelets below the hook-clamp for lacing, not two pairs, like the "Dutch" one. The "Dutch version" feature DMS (direct-moulded sole), and, of course, national ID-markings should be taken into account while identifying the manufacturing country of such boots.

In the process of localization of faults and "weak points" detection, the Armed Forces of the Netherlands, together with the German Bundeswehr, began a gradual transition to the boots model developed by "HAIX" company, the so-called "Model 2005/2007" (Mark 5/6). On the picture above one can see the Dutch military personnel in this new, high-quality, very convenient and constructively successful boots. They are well proven in a variety of weather conditions, especially in the European climate and awarded the best user reviews.

Currently, the Armed Forces of the Netherlands, following the latest trends in the development of army boots and taking into consideration the experience of the use of new models and footwear materials, solutions and technologies, are on their way to the new types of military boots. These boots are no longer of smooth leather, but are made of suede. The picture shows "Island MFS" model by German "Meindl" footwear company.

Mountain and Ski Boots of the Dutch Armed forces

For the mountainous terrain the Armed Forces of the Netherlands muses the boots, manufactured by "Alico Sport Di Altin F.&C. (SAS)", a famous Italian company from the city Chera di San Marco.

This short insulated boots are made of hydrophobic smooth black leather. The out-sole is a standard "Vibram" with classic tread pattern and additional stubs and grooves on the heels, intended for skis fastening. At the junction of the sole and leather upper these boots feature the reinforced rubberised bezel, a typical protective element for professional mountain boots.

Structurally, these boots have minimal number of stitches, one can mention protective leather pad on the rear side of the boots and soft damping "collar" on the boot's top. The lacing system is provided by three pairs of "D" -shaped rings and two pairs of hooks for lacing.

Exclusively for cartalana.com

We have much more interesting information on this site.

Click MENU to check it out!

∎ cartalana.com© 2009-2025 ∎ mailto: cartalana@cartalana.com