Rights Reserved - Free Access.

This digital object is protected by copyright and/or related rights. This digital object is accessible without charge, but its use is subject to written permission.

Unless expressly stated otherwise in the licensing conditions, you are free to make any of the acts permitted by your national copyright and related rights act, including browsing, printing and making a copy for your own personal purposes.

All other acts of reproduction and communication to the public are subject to the licensing conditions attached to the digital object.

ARMY BOOTS OF THE WORLD. REVIEWS

Important notice: we do not sell any boots! The prices are given for information purposes only!

Sweden ![]()

Swedish Military Boots Model M/90

The modern "Försvarsmakten" (Armed forces of Sweden) uses the camouflage uniform and boots of the same model M/90, developed in the year 1990. While the geometric- pattern Swedish camouflage is just an advanced modification of the German World War II camouflage, the Swedish army boots were specially designed by the order of the National Defense Ministry. The M/90 model boots are manufactured by two companies: "Arbesko AB" (the Swedish company) and "Sievi Oy" (the Finnish company).

Since 2000, "Arbesko AB" ceased to produce the boots for the Swedish Armed Forces, focusing on specialized boots for athletes, industrial workers and tourists, and all the production for the military was moved to Finland ("Sievi" factories).

The Headquarters and one of the plants of "Sievi" (full name "Sievin Jalkine Oy") are located in the central-western part of Finland, near the Swedish border, in the eponymous municipality of Sievi.

The company started its way in 1950 as a small footwear workshop. Initially the company specialized in the production of very popular rubber high boots with leather upper.

By the end of the 1950s "Sievi" developed into large industrial enterprise. During the 1960s, the development continued. The fall in demand for leather and rubber boots encouraged the company to shift towards leather boots production, and by the end of the decade the level of company's production was equal to a hundred of thousands pairs of boots per year. Over the next decade "Sievi" actively invested in labour safety technologies, as well as in R&D (research and development), that prepared the company well for foreign export. In the 1980 "Sievi" launched an export company in Sweden, which began the main exports market for the company. Not less important markets for "Sievi" became such countries as Denmark and Norway, also the exports to the UK, Canada and the countries of continental Europe increased gradually.

Having become one of the largest footwear manufacturers in Northern Europe, in 1991 "Sievin Jalkine Oy" became the first company in Europe, which received accreditation for quality management system according to the standard ISO 9000, environmental management system according to ISO 14001, as well as the right to use the CE label for safety requirements conformity. Currently, up to 60% of "Sievi" production is exported.

In autumn 2002 the company "Lapua n nahka Oy" and "CTE Leather Oy" were incorporated into the "Sievi Group", and the company's staff was increased from 490 to 560 people. In 2009, the manufacturing site in Sievi was increased by 4000 square meters, having resulted in 40% increase in production. Considerable part of the company's products was manufactured by the orders of Swedish Ministry of Defence.

Black Swedish M/90 army boots are available in two versions:

- Marching (summer) boots;

- Winter boots (with extra insulation)

In Swedish they are called, correspondingly, "Marsch Köngor M/90" and "Vinter Köngor M/90".

The prices for these boots in Sweden are, respectively, 1295 and 1495 SEK (Swedish Kroner).

Both types of boots are very similar in appearance and by design: leather upper and composite nitrile rubber out-sole, but the winter ones have an additional layer of insulating material, the insole and out-sole are thicker, the "influx" on the rubber welt is also higher. All these features allow to distinguish visually the different version of Swedish boots.

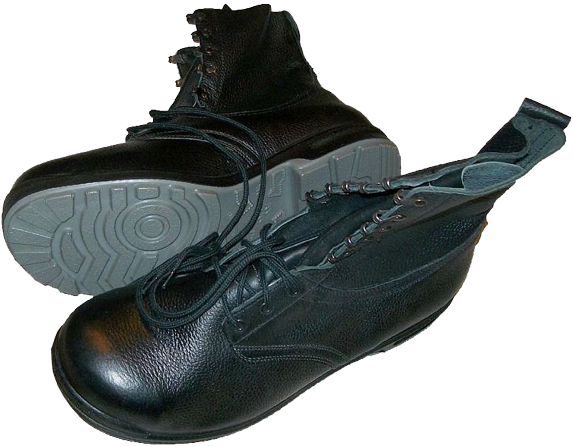

The design of the Swedish marching boots represented in the picture below.

The top is made of thick but flexible "grainy" hydrophobic leather. The flap of the tongue is "closed", i.e. Stitched down almost to the top of the boot. The lacing system is provided by three pairs of simple round eyelets at the bottom and five pairs of "MARK"-labelled bronze eyelets of speed-lacing system. Between these elements of the lacing system construction the cut-out is provided to make the legs bending easy. On the back side of the boot, the flat nylon textile "loop" is provided to keep in position the textile lacing, wrapped around the boot. This is typical Swedish design boots, with half-round stitches below the malleolus bones level, showing the border between the insulated and not-insulated parts of the boot (the upper part of the boot has no insulation).

The toe and the counter of the boot are reinforced, respectively, with plastic "toe-cap" and plate. The leather out-sole is reinforced with steel-plate arch support. The heel features the shock-absorbing cushioning, while the out-sole itself is composite in construction, and is made of polyurethane foamy rubber and nitrile rubber.

Usually the Swedish military boots are supplied with two insoles, the first one is made of thick felt and the second one, is thinner and made of textile with antibacterial impregnation.

The tread pattern is of an original Swedish design. The marking on the out-sole indicates the manufacturer's name, the size of the boots in "Mondopoint" system (in mm), and bears the Swedish "Three Crowns" logo (which should be obligatory eliminated (cut off) from the boots out-sole in the case when such boots are designated for civilian market sale.

The Swedish winter army boots of model M/90 generally correspond to the design of summer "marching boots", with the addition of thermal insulation layers. The felt in-sole is of double thickness (10 mm in "winter" boots vs 5 mm in "summer" model), the out-sole is oil- acid-gasoline-resistant. The nitrile rubber out-sole is light grey in colour, it is good for both normal and low temperatures.

On the Swedish discussion forums one can read that the quality of Swedish army boots has deteriorated in the recent decade. There are some suggestions that this is due to the transfer of production capacities somewhere to the South-East Asia, and the purchase of the footwear components there. It is hard to say whether it is true or not. We can say only that the labels on the Swedish M/90 camouflage uniforms indicate, that the uniform pieces were made in the countries like Indonesia, China, Vietnam, Sri Lanka, Tunisia or even Poland.

The out-sole of the Swedish M/90 boots, with all its undoubted advantages, still requires more attention and care than the earlier models out-sole made of thick and hard vulcanized rubber.

If to over-dry the boots near the home radiator or, for example, to expose the feet in M/90 boots close to camp-fire, the sole shall certainly degrade, disintegrate its structure and crumble. The result of such situation is clearly shown in the photo below.

The peculiarity of wearing the Swedish M/90 uniform is that the pants are not to be tucked into the army boots, but are to be worn over them. With this purpose, the design of the pants provides zipper on the outer sides of the pants. In the most recent versions of M/90 uniform, the pants feature additional patches of water-proof and easy-to clean fabric of green-grey color.

On the front lower parts of the Swedish army pants feature special button-tabs for fastening the pants legs to the lacing. The side zippers are also protected from water and mud by special water-resistant flaps on the buttons.

Swedish Military Boots for Summer (Model 01) - "Sommarkänga 01"

Swedish model M01 army boots ("Sommarkänga 01") for dry and hot weather were introduced in the year 2001. The Swedes themselves, with all their inherent Nordic humor, use to call them "Peter Pan Boots" ("Peter Pan Kangan") or just "Kermit".

Most likely, the reason for this nickname was the boot's appearance: they are made of green suede, while the out-soles are black. Indeed, some people annoying green boots, but it's a matter of personal sympathies or antipathies. In Norway, for example, the suede summer boots are of sand color.

According to the Swedish military sources, the "Sommarkänga 01" boots are just the modified version of the Swedish model M/93 navy boots ("Forsvarsmaktens Sjostridskanga 93"), which are made of black, smooth and more dense leather, with steel protective toe-cap. M/93 navy boots are to be worn as a part of naval uniform form, introduced in 1993. Wearing of this uniform and the appropriate footwear are defined by the Swedish Naval Regulation "Rattkladd 93" (shortly RÄK 93).

"Sommarkanga 01" boots are manufactured by the company "Sievi AB", a Sweden-based production unit of "Sievi Group". An interesting fact: under the terms of the contract between the Ministry of Defence of Sweden and the manufacturer, the delivery of these boots on the civilian market is limited. The approximate cost of a pair of these Swedish "Peter Pan Kängan" is about 500 Swedish Kroner, that is equal to 54 Euros as of mid-November 2014.

The design of the Swedish summer boots is as follows: the top is made of green-colored soft suede, the suede-made tongue is more dark in color and bears the marking. The lacing system is provided by 9 simple round eyelets; the boots feature "zippers" on the inner sides to facilitate quick pulling the boots on and off, even for a short break, and better drying and ventilation as well. However, zipper is a weak point as the boot can get wet boots through it. The suede itself absorbs moisture more quickly, compared with smooth skin. Under the rain, these boots get wet very quickly.

The relatively thin out-sole is made of black thermo-polyurethane, resistant to oil, petrol and various chemicals. The size range of these boots differs from 215 mm to 315 mm in the Mondopoint system. As compared with the model Swedish M/90 march boots, these "Kermit" boots are much more lightweight, cool and breathable. At the same time, "Peter Pan Kängan" are naturally more water-resistant than their naval prototypes of the model M/93. Instead of a steel toe cap, the Swedish summer boots of model 01 feature lightweight plastic toe-caps. The perforated tongue of such boot also made of suede, it is black and relatively thin.

The heels of the Swedish model M01 army boots to dry and hot weather are provided with shock absorbing inserts of foame polyurethane. At the same time, these shoes are not designed for long walks on feet. Any pair of such boots, according to the Swedish army standards, should include a pair of manufacturer-provided felt insoles (5 mm thickness). For the legs, they are not really as good, comfortable and high-quality anatomical insoles as personally tailor-made ones, so the Swedish soldiers often replace the regular insoles with the others, more preferable insoles immediately upon receiving of these boots.

A very important issue is the proper selection of the boots size. The regular Swedish army summer socks or "knasocka" (standard steel grey coloured high socks) fit these boots fairly well, until you decide to walk quite a long distance in Swedish "Peter Pan Boots". In such case it is recommended to put on two pairs of socks at once in order to decrease the friction of the skin with the inner surface of the boots, or it would be better just to choose some other boots...

Nevertheless, the Swedish military summer boots appeared to be quite good in peacekeeping operations somewhere in the desert, when soldiers basically use to move in vehicles and on foot along the unsurfaced or paved roads during hot dry weather. These Swedish model M01 boots are not suitable for long marches and field use in wet forest or jungle. According to the Swedish military regulations these standard boots are allowed to be replaced for other, more convenient footwear, which is to be purchased by Swedish peacekeepers in private.

Taking care for these boots and their cleaning don't require much efforts. They can easily be cleaned with a brush and some water. The suede boots are generally more open to injury and susceptible to damage as compared with the boots made of smooth leather. So the use of special protective impregnation is recommended for these boots, for example, "BOSTON 873 Super Protection Concentrate".

Swedish Military Rubber Boots Model M/90

Just as the Armed Forces of the neighboring Finland, the Swedish Army uses high rubber boots as one of the main types of military footwear. This decision is justified because the climate and nature of the eastern part of Sweden and of the western part of Finland are practically the same, and there are many lakes and swamps there.

The model of high rubber boots, currently used by the Swedish military, was introduced in 1990 as part of the new M/90 uniforms. The tread pattern and shape of the soles of the M/90 rubber boots are completely identical to the M/90 marching and winter boots, and all these kinds of military footwear are designed for skis fixation.

The main manufacturers and suppliers of the rubber boots for the Swedish Armed Forces are "Nokia Footwear Ltd." (the Finnish company) and "Acton International Inc." (the Canadian company).

"Acton" was founded in 1928 by Alfred Lambert, a businessman from Quebec. The company specialized in various kinds of rubber boots manufacturing for the army, police, firefighters, miners and industrial workers. The name comes from the town of Acton Vale in the Province of Quebec. In 2004, "Acton" was incorporated into "Regence Footwear Inc." company.

The design of model M/90 rubber boots is shown in Figure:

- The top ois made of laminated black butyl rubber, resistant to low temperatures;

- Oil-, acid- and petrol-resistant elastic rubber out-sole with ribbed welt for ski bindings;

- Reinforced toe and counter, i.e. plastic toe-cup and plate respectively;

- The heels feature shock- absorbing insertions of foamed polyurethane;

- Inside the boots there are non-removable felt insole and two removable insoles (felt and textile insoles of 4 mm thickness);

- Removable textile "sock" - thermal insulation liner;

- The top rear side features lacing for width adjustment plus folding flap for easy boots putting on;

- The outer surfaces of each boot's side show rubber patches with military marking.

In general, the boots of both manufacturers meet the Swedish military standards and differ only by the producers labels. By impressions of some users, the Canadian rubber boots are more rigid than the Finnish-made ones. On the outer sides of the rubber boots there are special patches, the marking on which indicate the emblem of the Swedish Armed Forces - the so-called "Kronmärkt" (Three Crowns), the size in the "Mondopoint" system, the manufacturer's name, the name of the footwear (rubber boots model 90), the country of manufacture, the European standard for safety boots with which these rubber boots are compliant, some other conformity markings like CE, HRO etc.

The removable sock-shaped textile thermal insulation liner bears the "Kronmärkt" (Swedish military marking) along with the year of production, the size range of this pair of the rubber in the "Mondopoint" system, the military identification number, the composition of material (47% cotton, 21% polyester, 32% polypropylene), care instructions (washing temperature, the acceptable ways of drying), the name (and country) of the manufacturer.

The out-sole marking also indicates the name (and country) of the manufacturer, other military markings the "Three Crowns" ("Kronmärkt"), the year of production and, finally, the size in the "Mondopoint" system. The weight of a pair of boots is approximately two and a half kilograms plus or minus few hundred grams, depending on the boots size. When selecting the size of the Swedish rubber boots should, one should take into account that in addition to the thermal insulation liner, which is provided with the Swedish rubber boots, another pair of socks (cotton and wool) for each feet is recommended for better thermal insulation, so you'll have to choose the rubber boots from half a size to one size larger.

Swedish Military Boots (from the 1940s to Model M/59 Boots)

From 1940s and up to the early 1990s, the Armed Forces of Sweden ("Försvarsmakten" in Swedish) have been using mainly medium height boots. In the last decade of the 20-s century the M/90 model boots (developed and approved in 1990) were introduced. What about the colour of the Swedish army boots, one should mention that in 1940-1960s they were brown, and in 1970-1980s these boots were black. However, colour change did not seriously affect the design and materials of these boots.

In 1959, the Swedish boots model M/59 was introduced, and today most Swedish boots, manufactured before 1990 use to be called this name.

According to the thematic forums, during the Anglo-Argentine war for the Falkland Islands (spring 1982) the British troops used to wear the Swedish army boots model M/59, which appeared to be great for cold and wet weather, typical for cold season in South Atlantic region. Today it is hard to say exactly, whether that's true or not.

In the 1940s the boots featured thick leather sole, stitched and glued. The toe and the heels could be reinforced with steel tips. The heel itself could be made of hard rubber, or composite of leather layers.

For easy mounting the skis the longitudinal grooves were made on the heels. With the same purpose the shape of the boot's toe was approaching rectangle.

Several designs of the boot's top were used: some of them were similar to American army boots (with reinforced toe and counter):

to purely Swedish design boots, which had minimum number of stitched joints.

The flap of the tongue is stitched to the boot's top, and the tongue itself is made of soft leather. On the tongue, the following information is indicated: size, width and "Kronmärkt" ("Three crowns") logo (the sign of belonging to the Swedish Armed Forces).

The marking was either hot-stamped on the leather or made by dot-punching.

The lacing system consisted of eight pairs of round aluminium eyelets, the laces could be either made of leather or textile.

The Swedish boots of model M/59 (shown at the pictures), which were manufactured until 1990, have a number of similar characteristics, such as minimum number of construction joints. In the early years the lower part of the boot's top was made of rubberised leather, the upper part was made of leather of more light and saturated colour. Later the leather of the same type and colour was used for whole boot's top.

The mid-sole of the Swedish boots model M/59, both of brown and black variants, is made of thick leather. The hard rubber out-sole, produced by "TRETORN", is glued and stitched to the mid-sile, the heels are additionally reinforced by boot's nails.

The marking the Swedish Armed Forces ("Kronmärkt") should be necessarily present on each piece of military stuff. "Kronmärkt" consists of three open crowns, one above the other two crowns. This emblem is a part of the Small Royal Coat of Arms of Sweden. It is also a traditional sign of the Swedish Armed Forces. The history and the meaning of this heraldic emblem are interpreted in different ways.

According to one version, this emblem was finally adopted in the years of the so-called "Kalmar Union" ("Kalmarunionen" in the Swedish, Danish and Norwegian languages), the personal union of Sweden, Denmark and Norway under the supreme authority of the Danish Kings (1397-1523). "Kalmar Union" has become the answer to the German Hanseatic cities trade expansion to Scandinavia. Three crowns, respectively, were to express the unity of Sweden, Denmark and Norway.

However, the "Three crowns" had been present on the Swedish Coat of Arms before the Kalmar Union, and no one can say for sure about the origin of this emblem. Undoubted is the importance of the sacred number "3": the Holy Trinity, the cult of the "Three Kings", who came to worship the baby Jesus, symbolically representing Europe (Magus Melchior), Asia (Magus Caspar) and Africa (Magus Balthasar, the Moor).

Perhaps the origin of the three crowns comes from the Dukes of Mecklenburg Coat of Arms, who occupied the Swedish throne in the fourteenth century. The latest version sounds re close to the truth, because the three open crown has become the main symbol of Sweden under the rule of King Albert of Mecklenburg.

One of the types of low black ankle boots, which were supplied to the Swedish Royal Air Force, had leather strap with metal buckle except normal lacing system. The design of these boots is different from the standard Swedish one, and more closely they resemble the design of the Italian boot for paratroopers (the lacing reaches almost the toes). The same system is used today in some kinds of army boots, because it is believed that it allows to adjust the boots width to the feet in the best possible way. The out-soles of these boots are made of solid vulcanized rubber.

The out-soles of these boots are of the standard Swedish tread pattern, but sometimes the tread pattern come across variations, such as it was with black boots of the 1970s. The toe and the heels are often reinforced with the screws (tips).

The flap of the tongue is sewn to the top of the boot. The rear side of the boot's top represent by itself a separate gusset, made of a single piece of leather, which prevents rubbing of the heels with in-seams. In such a way a problem, typical to the standard design boots, was solved.

The Swedish brown boots of the 1960s feature the following marking inside the boots: the duplicated data about the manufacturer (e.g., ABDS Docksta), the year of manufacture (e.g., 1964) and the size in millimetres (in "Mondopoint" system).

The traditions of the "old Swedish footwear style" are still continued by the shoe-makers of the "Lundhags" company, which offer a wide selection of traditional design high-laced boots.

The Swedish footwear company "Lundhugs Skomakarna" was founded back in 1932 by a local boot-maker Jonas Lundhag. Many generations of his ancestors specialized in the manufacture of leather boots. Jonas started his footwear production in a small workshop in the outskirts of the northern Swedish town Östersund. After 41 years, his factory grew big and moved to Järpen, being located near the Åre village, which lies on the way to the West Jämtland mountain range.

The company produces a very expensive and high-quality boots for tourists, climbers, military, and general fans of extreme outdoor recreation. The price of a pair of boots is about a few hundred Euros, depending on the model. However, unlike many of today's footwear manufacturers, with produce low-quality cheap "crappy" boots with small lifetime, the "Lundhags" company offers a repair service of its products irrespective of the period of their production, even up to the complete soles replacement. The "seasoned" travellers know that the best boots - are the good-quality "broken-in" boots. Therefore, the idea that the "soles replacement and repair are much more preferable than buying new boots" is justified from all the points of view.

The sources of the photos and information:

http://feldgrau.ru

http://iacmc.forumotion.com

http://lundhags.se

http://pprune.org>

http://soldf.com

http://sturm.com.ua

https://varusteleka.com

www.desertrat.se

www.mil-con.se

Exclusively for cartalana.com

We have much more interesting information on this site.

Click MENU to check it out!

∎ cartalana.com© 2009-2025 ∎ mailto: cartalana@cartalana.com