Rights Reserved - Free Access.

This digital object is protected by copyright and/or related rights. This digital object is accessible without charge, but its use is subject to written permission.

Unless expressly stated otherwise in the licensing conditions, you are free to make any of the acts permitted by your national copyright and related rights act, including browsing, printing and making a copy for your own personal purposes.

All other acts of reproduction and communication to the public are subject to the licensing conditions attached to the digital object.

ARMY BOOTS OF THE WORLD. REVIEWS

Important notice: we do not sell any boots! The prices are given for information purposes only!

Spain ![]()

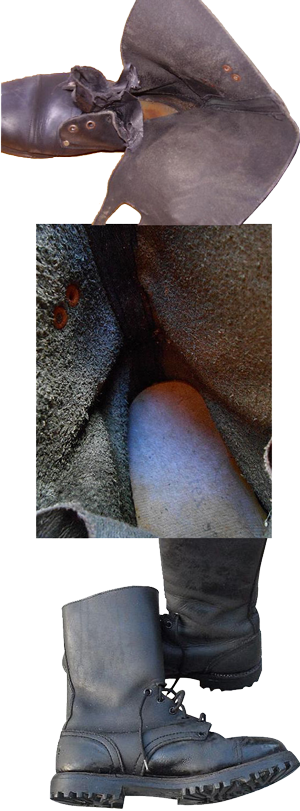

Spanish triple buckled "Segarra" boots (Botas "Segarra" de tres hebillas)

The classic "Segarra" boots of three buckles, which has become the traditional and most recognizable footwear of the Spanish Armed Forces, were introduced by military regulations in the year 1964. Before that the Spanish troops used to wear low combat boots with gaiters or high jack-boots with the buckles.

For several decades the Spanish conscripts had to wear these boots on their feet during the compulsory military service, at least until the mid 1980s, when the accelerated industrial restructuring was carried out in Spain in all types of manufacturing sectors.

These boots were made of thick and smooth leather, and they featured stitched and glued soles ("Goodyear"-type welt construction), that's why they can be repaired easily, and, in case of need, the out-soles can be swapped and renewed many times. The thick leather mid-sole was glued to quality black hard rubber out-sole, with very recognizable "angle-shaped" Spanish type tread pattern, which was used widely in Spanish Armed Forces, not only for these triple-buckle boots, but on the other boots, designed, for example, for marines, paratroopers, etc.

The Spanish triple buckled boots feature reinforced and stitched toe area (the shape of which is formed with an additional leather layer), reinforced heel counter and an additional leather straps on the rear sides, middle-size leather boot's tongue, stitched high on the level just above the lacing system, which is formed by five pairs of simple round eye-lets.

The lacing system construction is reinforced with a pair of additional metal rivets on the left and right sides.

An ex-soldier of the Spanish Armed Forces, elyeti wrote about his experience of using the Tres Hebillas boots by Segarra on

"En mis años de soldado en el ejercito Español, en un regimiento de Cazadores de Montaña,utilizabamos unas botas de dotacion marca Segarra. Heran unas botas estupendas, de cuero negro, con 3 hebillas en la polaina, una suela de caucho negro estupenda, eso si, al principio costaba domarlas, pero luego con un poco de betun negro de mantenimiento, lo aguantaban todo. Pateadas, marchas, instruccion, taconazos, maniobras, orden de combate,barrigazos, etc, etc, y las jodid...para adelante, MI PAR ME AGUANTARON CASI 2 AÑOS EN ESTE INFIERNO",

that can be translated as:

"In my years of service in the Spanish army, in the Mountain rifle regiment, we used the government issue boots, manufactured by "Segarra". Great boots, made of black leather, with 3 buckles on the pulley, with super out-soles of black rubber, and after breaking-in at first cost, then they need just a little treatment (with black shoe-cream), and they can put up with that all: kicking, marches, training, heel-kicking, maneuvers, combat order...уtc, and the fucking ... forwards, MY PAIR HAS BEEN WITHSTANDING ALMOST 2 YEARS ON THIS HELL."

As one can see on the pictures above, the inside of the Spanish "Botas "Segarra" de tres hebillas" are made of rough-out natural leather with terry-like surface. This allows gooв temperature balance and ventilation, supported with the overall construction of these boots: the lower part is waterproof and rigid, it fixes the feet safely and protects them against mechanical injuries. But the upper part, which is safely closed with triple buckles and leather belts gives enough spare space for air circulation and natural extraction of the feet perspiration.

Then, elyeti wrote about his opinion about the modern boots: "Actualmente, es muy dificil encontrar botas con estas caracteristicas, sin goretex, una membrana que nos la venden como la crem de la crem, pero que no es para tanto, pues cuando la bota se moja no transpira y se moja el pie con el sudor... por que entonces si que no transpiran, en resumen que a mi personalmente no me gusta,aun teniendo un par de botas de ultima generacion con estos materiales. Despues de mucho mirar no encontre nada parecido a lo que utilicemos aquellos años castrenses, hasta que, tonto de mi, Segarra sigue fabricandolas, no las de 3 ebillas, si no las Paraka (las que utilizaban los paracaidistas, sin ebillas, de caña alta con cordon) y se nos caia la baba viendoselas en las maniobras conjuntas, en aquellos años heran las mejores..."

"At the moment, it is very difficult to find the boots with such characteristics without Goretex membrane, which they sell to us like the best, but that is not so much, because when the boot gets wet it does not perspire and thus the foot gets wet with the sweat. ... if they do not perspire, in short that I personally do not like, even having a pair of boots of the latest generation with these materials. After much looking I did not find anything similar to what we used those years in the Armed forces..."Segarra" is still making such boots, not those of 3 buckles, but the Parakas (the ones that have been used by the paratroopers, without buckles, laced high with the cord) and we were drooling over that good-looking boots when we saw them during the joint maneuvers..."

The "Calzados Segarra" company, founded in 1882, is situated in La Vall d'Uixó, a town in eastern Spain, in the Valencian province of Castellón. The company is known on the local Spanish market since the year 1882. Nowadays the company manufactures different types of footwear: military and hunting boots, work and safety shoes, trekking, mountaineering and hiking boots.

According to the web-site of the "Calzados Segarra", the company is still using the concepts, which are very attractive for modern customers, which hate cheap and low quality Asian fakes:

1) Handmade process - it still uses 100% of manual labor;

2) National manufacturing - its manufacture is carried out in national territory of Spain;

3) Using quality natural leather;

4)The out-soles are fully manufactured of rubber, a material of natural origin, totally recyclable and offering enormous resistance to flexion and abrasion, strong adhesion to the ground, and resistance to the wear.

The boots, which were mentioned by the aforementioned elyeti, are, in fact, manufactured by "Segarra" instead of "good old" triple-buckle boots, and which are commercially available under the brand name "Model 3001 Paraka" for about 42 Euro. The name "Paraka" comes from the Spanish word "Paracaidista", i.e. "Parachutist".

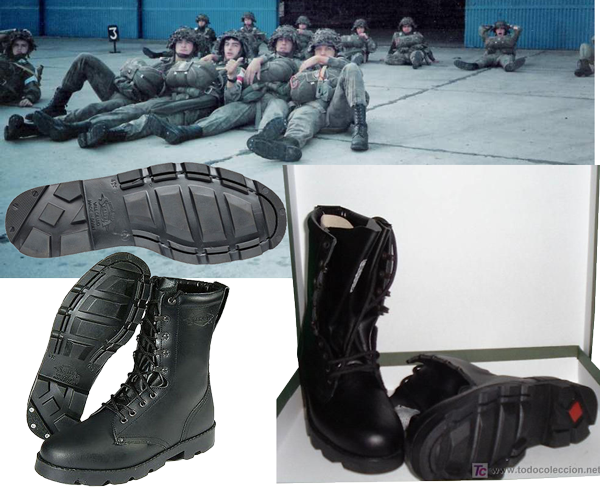

Of course, the modern "Model 3001 Paraka" boots are the modern version of the "good old" paraboots, and they feature such comfortable novelties as padded collar on the top of the boots, elements of quick-lacing system (four pairs of simple round eyelets in lower part of lacing are combined with four pairs of quick-lacing eyelets in the upper part and a pair of round eyelets on top), padded boot's tongue, leather loop for laces on top rear side, and modern "Panama-type" out-sole (Spanish version).

These new boots are manufactured in sizes from 36 to 47, the thickness of the upper leather is 1,8 mm, these boots have no lining, the removable insole is made of Thermoformed EVA. The rubber "Paraka" out-sole is stitched and glued and sewn, and all the eyelets are made of rust-free metal.

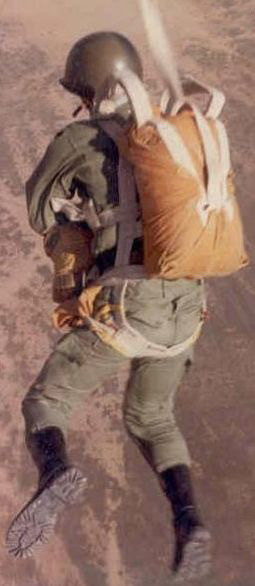

The "paracaidista" boots of the 1960-1980s were much simple, they featured "Segarra"-type out-soles with angle-shaped lugs on their tread pattern, and the out-soles were very thick, they had simple round eyelets (12-13 pairs), but no padding on top.

These boots were originally designed for the Spanish paratroops, and the examples of their use can be seen on the photos below.

Before introduction of high laced boots for "paracas", the Spanish paratroopers used leather gaiters, which were fixed on the ankles with the help of the lacing system and served as a protection against injuries, sprains and bruises - these gaiters were already mentioned in the review of the Argentinean combat boots of the Falkland war times.

The photos above were made in 1957 and show the feet protection equipment of that time.

Further on the high laced boots without the buckles, which had been used by the paratroopers for years, were adopted as a new type boot for the other branches of the Spanish Armed Forces

In 1980-s, "Segarra", the main footwear supplier of the Spanish Armed Forces of that time, faced with the problems, connected with so various boots manufacturing, supply and delivery according to the Contracts with the Spanish Ministry of Defense, which tried to purchase the boots for less price.

So the Ministry managed to find another alternative Spanish boots manufacturer - "Industrias Mediterraneas de la Piel SA" (brand name "IMEPIEL"), whose premises were located in Vall d'Uxó (Castellón province), and extended to 150 km2 with buildings occupying some 100 km2 of this. Vall d'Uxó is a town of 27 000 inhabitants 45 km to the north of Valencia, 26 km from Castellón and 15 km from Sagunto, a town which has suffered recently due to the rationalization of the steel industry.

"IMEPIEL" was manufacturing and selling its footwear produced from its own preparation of hides and from rubber, a purely intermediate product, which was used for the out-soles manufacturing. However, the company has faced with hardships, connected with lack of good management and other financial obstacles.

"IMEPIEL Case" - Reference Information

According to the European Commission Decision (92/318/EEC) of 25 March 1992 on aid granted by Spain to Industrias Mediterraneas de la Piel SA ("Imepiel") one can learn, that "Imepiel" was incorporated in 1882 by the Segarra family who owned and managed the company until its acquisition to stave off bankruptcy by the Spanish State in 1976. At this date the Spanish State, through the Property Office of the Ministery of Economic Affairs ("Patrimonio del Estado"), acquired 99,94 % of the capital, the other investors being the "Caja de Ahorros de Valencia" and the "Caja de Ahorros de Castellón".

Earlier, during the post-war years, the company expanded diversifying into complementary activities such as glove making and farming. Since its acquisition by the State such ancillary activities have been eliminated. Despite this the company has always been one of the leading Spanish footwear manufacturers having the largest workforce and highest production capacity located on one site.

However, since rationalization, cuts have been made resulting in a reduction in the workforce from 3 146 in 1976 to 1 457 in 1988. Throughout the period of public ownership the company has, in general, incurred operating losses each year. Over the 10 years to 1987 these amounted to 12 700 million Spanish pesetas and a series of capital injections were made to cover these losses. In addition, publicly-funded capital investment expenditure has been incurred in an attempt to modernize the factory.

Faced with continuing losses the majority shareholder commissioned a viability plan in the mid 1980s which foresaw a reduction in capacity due to redundancies; capital injections (1987: 1 400 million pesetas, 1988: 1929 million pesetas); a managerial shakeup and a reassessment of markets and products.

The support of "Imepiel" from the side of the Spanish government caused the objection of the UK-based British Footwear Manufacturers Federation, which stressed that Spanish imports had increased in the UK and that these shoes competed at the lower end of the market where competition was price and not quality based. Therefore, any State aid enabling a manufacturer to reduce his sales price would have a negative effect on competition. The British position within the EC was supported by some other countries as well.

The Spanish authorities had long period of lettering and discussions with Commission on the matter of recovery plans details, aimed at the following objectives:

- to return the company to profitability within three years,

- a reduction in capacity: footwear from 3,2 million pairs per year to 1,74 million pairs, hides from 20 million square feet per annum to 14,1 million square feet and the closure of the rubber section,

- a decentralization of the company's organization,

- rationalization of the manufacturing premises with the sale of superfluous space,

- expansion of own brand sales and an attempt to move into higher quality products,

- the avoidance of labor disputes through detailed negotiation,

- a reduction in the workforce from 1 457 to 627.

But the company faced with really hard times - it neither earned a profit in 1988 nor 1989; in addition, subsequent plans have indicated that it will not be profitable before 1993. The foreseen reduction in capacity may have been possible but production was, for shoes, 2 million pairs in 1987 and 2 million pairs in 1988. Subsequent plans indicate production in excess of 2 million pairs in 1990 and 1991 and over 3 million for 1992.

"Imepiel" was privatized on 2 February 1990, being sold for 100 million pesetas to the highest bidder - "Circulo de Financiación y Gestión SA".

Community footwear production amounted to 1 050 million pairs of shoes and was following a declining trend which had caused a shrinkage of about 15 % since the year 1986.

The industry assembly employed 360 000 people directly and another 140 000 people for indirect and ancillary (hides and components) production; the sector was characterized by its fragmentary structure with a large number of small businesses (about 15 000 units with an average workforce of 24).

In 1986 Spain had some 14 % of the European Community market in terms of production of which 61 % was exported; as "Imepiel" was a significant producer in terms of the number of personnel employed and is an above-average shoe producer, in volume terms, it was taking a more than marginal share in the Community market.

Taking into account that "Imepiel" was granted aid by the Spanish authorities in the form of capital injections, between 1986 and 1988 amounting to 6 029 million pesetas, the EC has adopted the decision, according to which the aid was granted illegally, as it was done in breach of the procedural rules.

It is worth mentioning that the Spanish footwear market, in which the goods were produced and sold by "Imepiel", was highly competitive and still is that. The EU footwear market is described as even more "highly competitive", and the aid is deemed to distort competition even though the firm in question produces less than a third of 1% of the Community footwear market. ...If this sector is truly characterized by intense competition, then the only impact of state aid is (at worst) a waste of the member state's own tax resources, not any cross-border effect on the competitive situation faced by firms in the other member states.

The European Commission Decision 92/318/EEC is just an example showing the presentations of inter-state and inter-market competition, performed in all the possible ways.

Both "Segarra" and "Imepiel" were manufacturing boots with the out-sole tread pattern, which looks similar to the French paratrooper's boots BMJA Mle 50 of the 1950-s:

There were some Spanish-made boots, which look very similar or just the same as the French BMJA-65 combat boots. The only visible difference between the original French combat boots and the Spanish BMJA-65-type combat boots made by "Iturri" is the absence of manufacturer's labeling in round circle (name and the city, where the factory is located along with the date of production).

The Spanish version of the BMJA-65 boots feature the following information: size and width in European metrics (39/7) and Mondopoint (245/97), and the Contract data.

I can suppose that this kind of boots were manufactured on Spanish manufacturing sites, equipped with SAMCA (footwear assembly automated system), which is being developed withing the EUREKA-FAMOS EU-285 project. The project was developed by a French-Spanish partnership, where the Spanish side was represented by research institutes INESCOP and DISAM, together with footwear manufacturing companies IMEPIEL and MERQUINSA.

The main feature of the proposed assembly system, in contrast to the previously used hand-made technologies, was that parts remained fixed on pallets during the process, which are placed, by means of transport system, into different machines and robots, in order to perform automatically several operations, which were carried out manually before that.

SAMCA system had to be modular, in order to be installed in different stages in medium and small sized factories, and intelligent enough to allow the input of components made by different subcontractors, which could have acceptable deviations from the standard.

The French influence can be obviously seen in some other boots of the Spanish Armed forces.

The photos above show Spanish "paracaidista" high leather boots with 12 pairs of simple round eye-lets manufactured by Iturri. They feature very interesting out-sole tread pattern resembling the ones of the famous French BMJA Mle 52 "Rangers Marrons".

The sole is stitched and glued to the boot's top just in the same way at it used to be in that old French boots.

Also there were Spanish double-buckle boots with yellow leather lining - they resemble both French BMJA-65 boots (the overall design of the boot's top) and German Bundeswehr paratrooper's boots.

Perhaps, these boots might be manufactured by a contract for the French Gendarmerie, because such type boots were a part of their uniform.

Mr. Oscar Velázquez, a member of the Spanish Civil Guard (an organization with the functions similar to the French National Gendarmerie or the Italian Arma dei Carabinieri), has informed me, that the boots with yellow leather lining were called "Botas de Intemperie" (That can be translated as "the boots, exposed to the outdoors" or simply "boots for bad weather") and they were little distributed. Usually they were marked with boot's size in Mondopoint system and the year of manufacture.

"Imipiel" was manufacturing the boots, which were very similar to the ones, produced by "Segarra", with the same looking boot's top and the out-sole tread pattern.

According to the customer's opinion, the quality and durability of the "Imepiel"-made ones was worse, they lasted less and sometimes there were problems with the out-soles adhesion to the boot's top. No wonder, taking into account the information about the company's financial problems, stated above.

But the Spanish Ministry of Defense had to solve the problem of mass supply of the combat boots to the national Armed Forces. So, they decided to improve the out-soles of the "Imipiel" boots by withdrawing the previous types soles and replacing them with more advanced "Panama"- type soles, having in mind the idea to fix the problem of the out-soles separating from the boot's top.

Mr. Oscar Velázquez also informed me, that most boots were manufactured by such Spanish manufacturers as "ITURRI", "VIDAL", "SEGARRA" and "IMEPIEL". In the period from 1986 (year of joining NATO after the national referendum and the appropriate political decision of the year 1982) to 2010 these boots were called "Botas Instruction" (i.e. "boots for training").

These black boots had no lining of any kind, they featured "Goodyear" welt construction, four pairs of simple round eyelets in the lower part of lacing and a pair of such eyelets on the top, between them there were four pairs of "MARK" speed-lacing eyelets. The out-sole tread pattern was "Panama" -"ABRAX".

Among the boots, provided to the Spanish Armed Forces from 1986 to mid 2000, Mr. Oscar Velázquez mentioned the boots of the "ITURRI" brand, which featured coated textile tongue that used to crush down easily.

He used such boots in summer months from June to September for work, since they were not very hot, but these boots appeared to ne quite uncomfortable and needed an insoles.

Mr. Oscar Velázquez said, that usually the Spanish soldiers preferred the boots by "VIDAL" and "SEGARRA" to the ones by "ITURRI" and "IMEPIEL" since the latter had harder leather and were less well built. This model in addition to the Armed Forces was used by the National Police Corps and the Civil Guard of Spain. Overall they were very durable but uncomfortable, they were not warm in winter. Nowadays the boots of the Armed Forces are of "pistachio" color, the police uses the "Gore-TEX"-lined models, while the Civil Guard from the year 2011 is provided with the boots of another model with "Gore-TEX" lining. These models will be considered in an a separate review further on.

This step has opened a new era of the Spanish military boots out-soles. The famous American "Panama" out-sole was tested during the real war in Vietnam and proved its superiority in damp and wet jungles, on muddy terrains and slippery slopes and hills.

The Spanish Armed Forces not only adopted "Panama" out-sole tread pattern for their own national boots, but invented different variations of the "Panama" sole:

- with adding additional elements like extra shallow lugs on the heel and toe areas of the sole,

- deep grooves for stitching along the edges of the sole and metal screws (tacks) in the toe and heel areas.

On some boots of such type one can see red-colored square lug in the center of the heel tread pattern. I didn't find any trust-worth information about this peculiarity, but I can just suppose that red-colored lug means thermo-stability of the sole and its ability to withstand high temperatures, similarly to the "blue lug" on the modern "Fire and Ice" out-soles, intended to withstand low temperatures.

- A very recognizable Spanish variants of "Panama" out-sole tread pattern, which differ from each other in small details, like size, location and shape of the grooves on the heel...

At the same time the Spanish Ministry of Defense initiated the researches aimed at creation of a new concept of the combat boots, taking into account the most advanced ideas and solutions. The new model lacked the traditional triple buckles and was full-laced, as it used to be in a former paratrooper boots. The list of manufacturers of these new boots was opened for new producers, the most famous of which were such Spanish footwear manufacturing companies as "Iturri", "Vidal", "Invulsa". There also were some smaller companies, like "Sancho", "Catosa" and many others....

Exclusively for cartalana.com

We have much more interesting information on this site.

Click MENU to check it out!

∎ cartalana.com© 2009-2025 ∎ mailto: cartalana@cartalana.com