Rights Reserved - Free Access.

This digital object is protected by copyright and/or related rights. This digital object is accessible without charge, but its use is subject to written permission.

Unless expressly stated otherwise in the licensing conditions, you are free to make any of the acts permitted by your national copyright and related rights act, including browsing, printing and making a copy for your own personal purposes.

All other acts of reproduction and communication to the public are subject to the licensing conditions attached to the digital object.

ARMY BOOTS OF THE WORLD. REVIEWS

Important notice: we do not sell any boots! The prices are given for information purposes only!

Poland ![]()

Tactical Boots "GROM" (Trzewiki "GROM") of Poland

According to the manufacturer information, light black tactical boots "Grom" (the "Thunder") were specifically designed for special forces and police units Poland. It is alleged that these boots were named after the same-name Polish anti-terrorist unit created in 1991.

The activities of the Polish special unit "Grom" is to great extent classified. Even the establishment of this team was announced by the authorities only three years later. So, most information about "Grom" unit is secret, but it is known, that it numbers up to 300 people, and each battle group consist of four well-trained fighters. The women can also serve in the"Grom" unit, presumably as intelligence agents, but any more detailed information is secret.

It is also known that all the members of the unit "Grom" are trained according to the program of special forces units, three-quarters of them are qualified doctors. Each member of the unit knows at least two foreign languages, and is not only a well-trained climber, sniper and frogmen (according to the US Navy SEALs Programme), but also a statesmen bodyguard.

In particular, it was the Polish "Grom" in 1994, which ensured the safety of Boutros Boutros-Ghali, the UN Secretary-General and William Perry, the US Secretary of Defence. Contrary to the practice in the United States Army and for its professionalism, the Polish "Grom" unit was awarded the "The Army Commendation medal" of the US Army. The award was handed over to Colonel Slawomir Petelicki, the creator and commander of this unit.

However, not everything went smoothly in the life of "Grom" unit , as well as in the contemporary US, British and other special forces. In October 1999, the unit was transferred from the Ministry of Internal Affairs to the Ministry of Defence, and passed through repeated reforms and renewal of the staff.

At various times, in many countries, including Poland, the special forces were on the verge of disbanding and liquidation for political reasons.

Later, the founder and the first commander of the "Grom" unit admitted that it were the wars, which saved the unit from disbanding, and the personnel - from forwarding to different units of the army and navy, because "Grom" was actively involved in the operations in Afghanistan and Iraq.

As a part of the Ministry of Defence of Poland, "Grom" unit is still responsible for solving the problems of the counter-terrorist struggle. There are some new challenges as well: the "Grom" fighters undergo the training as a commando (even partisan) troops, fulfilling the task of fighting the enemy in case of hostile invasion on the territory of Poland.

In modern Poland, the special unit "Grom" enjoys an excellent reputation and respect.

As for the same-name boots, some Polish sceptics on the military forums argue that this sounding name is just a "marketing ploy". However, the truth is somewhere in the middle between the two polar opinions.

Whatever it was, today "Grom" tactical boots are among of the most popular models of tactical footwear of the Polish security forces and among civilian hikers, hunters, guards...

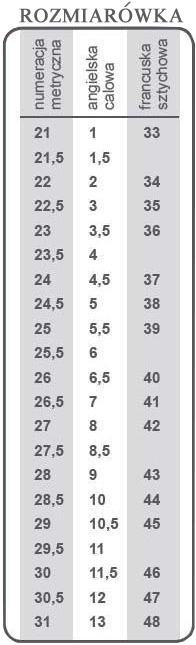

These boots are made of high quality soft calf leather, combined with "Cordura - Traspira", a durable, waterproof and breathable textile material. The impregnation of the material provides protection from outside moisture and good resistance to mechanical damage. The boots sizes range from 33 to 48 in French metrics. The boot's counters are strengthened with additional layers of the leather inside. The weight of pair of boots is 1.2 kg for size 42.

"Grom" boots are produced only in black. As it was told before, the material of the boot's top is leather + "Cordura Traspira" (in some descriptions this material is also called "ballistic nylon" - "nylon balistyczny", i.e. resistant to cut and tear, and various mechanical deformations). The out-soles is double-layer (polyurethane+ foamy polyurethane) and feature self-cleaning tread pattern of "Cheetah" type. This is exactly the same standard out-sole as used on the Polish army "desert" boots, but black-coloured. This is the DMS-type boots, i.e. with Direct Moulded Sole.

DMS method makes the boots light and flexible as sneakers or plimsolls, as well as strong enough and resistant to cracking, abrasion and slip. The profile of the out-sole tread (the heel is 13 mm in height) ensures quiet and safe movement on the most common surfaces of the urban environment: stone masonry, tile, asphalt, concrete, gravel, break-stones etc... It also allows the use of "Grom" boots on the "dangerous" surfaces, with potential risk for the out-soles to be exposed to the engine oil, fuel, solvent, acid etc. In other words, the out-sole material does not react with the aforementioned chemically aggressive substances.

The lacing system consists of three pairs of simple round eyelets in the lower part of the lacing system, above there are five pairs of "MARK" speed lacing eyelets. The laces of the "Grom" boots are round in section. Soft textile tongue is made of "Cordura - Traspira", i.e. the same material as non-leather part of the boot's top and is stitched high to the boot's top upper (the flap of the boot's tongue is almost "closed"). As distinct from most "jungle" boots, the sides of the boot's top near the malleolus bones are not reinforced with an additional layer of textile material. A soft velour padding "collar" in the upper part of the boots is up to 50 mm in thickness at the rear side of the boot's top, and serves to protect against the ingress of water, dust of small pebbles inside the boots...

The manufacturer also produces a model of "Grom" boots with entirely leather upper. The soft padding on top of the boot's upper is made of leather too, not velour, like the standard model. The lacing system was slightly changed as well: the lower pair of speed lacing eyelets was changed with a pair of hook clamps for laces fixation.

This boots are definitely more sturdy, that the standard "light" model, and the "Grom" leather boots out-soles tread pattern is of their own, Polish design. It can be assumed that the experience of Bundeswehr boots design was taken into account while creating these boots, because from the tread pattern of the Polish leather "Grom" boots resembles the out-soles of the German mountain boots by "HAIX" company.

The marking on the out-soles usually consists of the name and location of the manufacturer (Protektor - Lublin);

the features of the out-soles (antistatic, oil, petrol-resistant) and sizes (the round sign is divided into three sectors, each of which shows the size indication in Polish, British and French size metrics respectively). The photos show the examples of marking: the Polish size is 26 cm, the British size is 6.5 and the French size is 40), and the table of all sizes of boots, produced by the manufacturer - "Protektor SA" company of Lublin.

This choice of metrics is likely due to the possibility of such boots supplies to the Armed Forces of the Polish allies of NATO. This version can be also proved by the fact, that the manufacturer is possessed of the AQAP 2110: 2006 (Quality Certificate for military boots), as required by NATO regulations.

A pair of "Grom" tactical boots cost about 230 zloty (i.e. 55 Euros) in Poland.

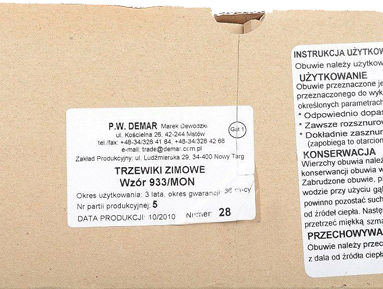

Polish Army Winter Boots Model 933/MON (Buty (trzewiki) zimowe vzor 933/MON)

The real Polish military boots differ from any commercial copies by the marking "MON", indicating the Ministry of National Defence of Poland (Ministerstwo Obrony Narodowej, MON).

The specific models of boots, made by the Ministry of Defense specifications, are designated by three-digit code, a slash and "MON" abbreviation, for example, 919/MON, 925/MON, 928/MON, 933/MON etc... This marking certifies that the certain pair of boots are made for the army by contract (kontraktowe, wyprodukowane specjalnie dla wojska).

Winter boots of the Polish army (model 933/MON) are designed for use at low temperatures and high humidity. The boots are made of several layers of leather: grainy calf leather, dense but flexible, with a hydrophobic impregnation as the outside layer, and thin black "glove"-type leather inside the boots. Between the leather layers there is thermal insulation and shock-absorbing lining, which, in combination with ventilation holes provide comfortable dry warmth inside the boot. Compared with the German Bundeswehr boots model 2005/2007, the Polish boots feature wider stitched leather "collar" padding at the top of the boots, providing improved protection against dust, moisture and preventing heat loss.

The process of 933/MON manufacturing involves new materials (insulation of "Thinsulate" microfibre (for conditions of high humidity); lightweight and sturdy "Cordura" nylon fabric, resistant to mechanical damage; "OutDry" membrane, placed directly on the inner surface of the boot's top leather; "Air Comfort" anatomical insoles of polyurethane/leather, providing better air circulation inside the boots, good thermal insulation, cushioning and shape retention, even after long-term use; the out-sole are made by "Vibram" or composite ones (made of polyurethane foam plus rubber or thermo-polyurethane).

By the outlook appearance and design of the boot's top the Polish winter boots model 933/MON resemble Bundeswehr boots model 2005/2007, and both types of boots feature the same:

- general design principles;

- the concept of a minimum number of seams;

- damping inserts on the back sides;

- speed-lacing system (the lacing hooks of the Polish boots have "streamlined " shape);

- the design of the boot's tongue;

- "closed" bi-layer structure the out-sole (polyurethane foam in the heel + rubber, resistant to abrasion and temperature changes), resistant to oil and acid, antistatic.

The similarity of the Polish winter boots with the new German army boots can be explained by the fact that the Polish company "P.W. Demar", which participated in the development of model 933/MON, was one of the German Ministry of Defence subcontractors, and have been producing Bundeswehr boots model 2005/2007 for several years. This was before the German company "HAIX®-Schuhe Produktions und Vertriebs GmbH" from the city of Mainburg "conquered" almost completely the market of military boots supplies for the German Armed Forces.

The company "Demar" produces the most diverse footwear for more than 35 years- from the shoes for kids and home slippers to the specialized and working boots. The company holds a considerable place in the footwear market of Poland and the Eastern Europe as well as in the Nordic and Baltic countries, so the Bundeswehr logistics had strong arguments to choose this company as a subcontractor at that time.

However, the further reducing of funding for the German Bundeswehr and the priority of the price criterion, the necessity to choose of a single German manufacturer, which could offer the best price in the supply of large consignments of footwear for the Bundeswehr. was inevitable

After the end of the Bundeswehr contract, the Polish boots, which are actually the analogues of the Bundeswehr boots Modell 2005/2007, are supplied by "DEMAR" to the commercial market under the brand name "DEMAR MASTER D12", but as a specialized footwear for civilian users. These boots can be ordered without difficulty on-line on the web-sites of the companies that specialize in selling of this company's footwear.

By their appearance, "DEMAR MASTER D12" boots are almost complete copy of the German "Kampfstiefel Modell 2005/2007", but they are dark cherry in colour, the stitching thread is red, also the boots feature bright red sewn-on manufacturer labels and colourful two-tone laces. These details are likely to give these Polish boots the look of a kind of modern "safety boots".

As for the Polish winter boots model 933/MON, one should mention among the contract manufacturers the companies "Protektor S.A." and "Wojas S.A." along with "Demar" company. Typically, all of the aforementioned manufacturing companies give a three-year warranty on their boots.

The largest of these three manufacturers is "PROTEKTOR S.A." of Lublin city, it is active player in the footwear market of Poland and Europe for over 65 years.

The company produces mainly military boots, as well as work and special purpose boots of leather. The company's products are designed for a variety of climatic conditions, and it is one of the main suppliers of certified footwear for the Ministry of Defence of Poland (MON). The company's process of boots production involves different methods of out-soles mounting, from "DMS-Direct Molded Soles" (direct injection polyurethane assembling) with the help of German "DESMA KLOECKNER" equipment , to glueing and glueing and stitching.

The company "Wojas S.A." of Nowy Targ city is more oriented on the market of civil footwear and stylish sport shoes, so army boots manufacturing is just only one, not the main, field of production.

The Polish-developed out-soles tread pattern of the model 933/MON boots differs from that used in the new boots of Bundeswehr and many other European countries (Belgium, Niderdlandov, Slovakia, Romania...).

On the out-soles of the Polish army winter boots it is usually specified by the manufacturer's name and logo, the size in the "Mondopoint" system, the model code - "933/MON", the month and the year of manufacture (just in the same way as on the Bundeswehr boots model 2005/2007) - in the circle stamp with arrow and numbers. The protective properties of the out-soles: anti-static, resistant to aggressive oil and chemicals etc. are also indicated.

The price of these boots in Poland, if ordered by the Internet, will be about 220 zloty (53 Euros).

Polish Military Boots Model 928/MON with GORE-TEX® Membrane

The Polish sources use to designate model 928/MON black army boots as the "special" ones, but in fact they are universal purpose boots, suitable for hiking, as well as for forest and swampy terrain, i.e. for virtually all tasks the modern army boots must be applicable. This model is also preferred by the Polish special forces soldiers.

The top of the 928/MON boots is made of hi-quality smooth cowhide of 2.5 to 2.7 mm in thickness, with hydrophobic impregnation, allowing the leather to "breathe." All the boots have to pass 100% control of waterproof features for the leather uppers, seams and joints between the out- soles and the boot's top. The process of hydrophobic impregnation consists in treating the boot's top leather with substances that increase the "water-repellency", after that the outer surface of the leather does not absorb moisture for at least six hours of continuous exposure in the water. The toe, the counters and the ankles are protected by special padding inserts. In the boots model 928/MON the "Bootie"-system is implemented: the membrane fabric is "sock-shaped", the seams are flat, at this waterproof features are provided.

These boots also feature GORE-TEX® membrane fabric, the tiny holes of which provide ventilation and natural feet vapours removal, therefore, it helps to maintain a comfortable temperature and humidity inside the boots, while keeping moisture from entering the boot, for example a drop of water is too large to get into the membrane material.

Only the special care products ("for membranes") are suitable for these boots. Any conventional means of footwear care and protection can clog the pores of the membrane and significantly impair its properties. The membrane fabrics use to be clogged over time even from simple use, and that's well known to the owners of such kinds of boots.

The out-soles of 928/MON boots are made by the Italian company Vibram® (tread pattern Fuora®), they are "self-cleaning" and universal, provide good adhesion to different surfaces, wear-resistant and antistatic.

Depending on the manufacturer, on some batches of 928/MON boots the out-soles are made by another, less famous Italian manufacturer "DAVOS", which also provides boot out-soles for the Armed Forces of Italy and Switzerland. In any case, the out-sole are made of slippery-proof, wear-resistant, oil and petrol-resistant rubber with antistatic properties.

A pair of 928/MON boots weighs more than two kilograms - they are quite heavy even as for the military boots. Therefore, with all their comfort in use the owner of these boots must have sufficiently strong legs for long hikes in them. They work well in the cold season - at a temperature from about -20 C to +10 C.

928/MON are sturdy, high quality and easy to clean boots with good water resistant features. Due to their design, they usually do not rub the feet, under condition of proper choice of size/width. It is recommended to choose the boots 1-1.5 cm larger than the actual size of the feet.

Soft leather "collar" is stitched at the top of the boot, as well as on most modern Polish military boots. The design of these boots resembles the Swiss army boots model M-90 - both models have wide rubber rim on the boot's side (at the junction of the leather top and the out-sole), intended to protect the boot's top from damage when used in the mountains). Polish 928/MON boots also resemble Bundeswehr boots models 2005-2007 (construction with a minimum of seams , damping inserts on the back side, the design of the tongue, ventilation system etc.).

The lacing system consists of eight pairs of speed lacing D-rings or 4 rings below plus four pairs of lacing hooks on top. The elements of lacing system are allocated in two blocks: four pairs of lacing elements in the lower part and four pairs in the upper part of the lacing, in the middle part there is a pair of self-locking clamps for the laces.

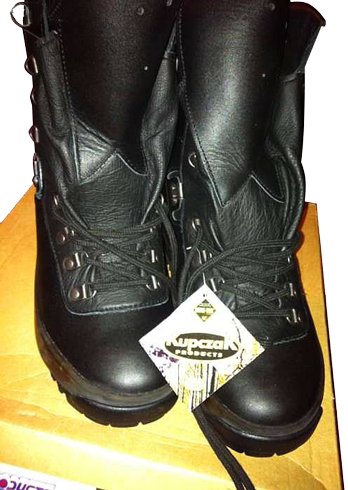

The boots model 928 (wz.928) are produced by several companies, the largest of which are: "Kupczak", "Demar" and "WOJAS". Judging by the reviews of the Polish users of these boots, the best ones are made by "Kupczak" ("PHUP Products m. Kupczak."), which is the developer of the model. We can not say that all producers, except the developer, just make copies or fakes, but in this case the logo "Kupczak" is the sole standard of quality.

According to the Polish legislation, the developers of any boots model, approved for the national Armed forces, should hand off all the rights on the model the Ministry of Defence, so did the "Kupczak" company. After this the developing company use to received the right to participate in tenders for the supply of these boots on a competitive basis.

So one can see a curious situation: the materials use in the original model 928/MON manufactured by "Kupczak" are high in quality and quite expensive (for example, GORE-TEX® membrane is not so cheap). But the specification, approved by the Polish MON, is in fact a simplified and generalized version, compared with the "know-how" design of the developer (for example, the specification prescribes the use of leather, nylon, membrane fabric and lacing eyelets of stainless steel).

The process of boots manufacturing in accordance with the developer's specification does not imply that the quality of the used materials (nylon fibre, fabric membrane, leather and impregnation chemicals, stainless steel) and manufacturing accuracy shall be as good as the developer intended. All these minor discrepancies and deterioration of small details, invisible separately, but taken as a whole led to higher price of boots by "Kupczak", as they are made by higher quality standards compared to all the other manufacturers. And, as it was mentioned before, the process of "Kupczak" boots manufacturing involves more expensive and higher quality materials. However, the minimum requirements for the manufacture of 928/MON boots, in general, are kept by all the other suppliers. So, "Kupczak" always win all the competitors, if not to take into account the price of their boots.

However, during the decisions making about the boots contract manufacturer for the Armed Forces, the most serious is the question about the price. So the situation is typical, when the worst but more cheap boots producers win the tenders. In such a way "Demar" and "Wojas" companies, whose quality can be called no.2 and no.3 after the no.1 leader ("Kupczak") used to get contracts. It turned to the situation, when the Polish Ministry of Defence no longer ordered the army boots from "Kupczak" in the last couple years. Practically the entire contract was granted to "Wojas", which even does not use the GORE-TEX® membrane (instead of inscription "GORE-TEX®" inside the boot, the manufacturing company simply indicates "Wojas"), and makes use of the other, cheaper materials to offer less expensive final products.

This issue was vigorously discussed on the Polish discussion forums and the Poles did not hesitate to use strong expressions, for example, one user wrote:

"...Czemu KUPCZAKI są lepsze od Wojasów itp.?? I jeszcze raz zaznaczam że warto dać nawet i 400zł za Kupczaki bo za 400zl trudno kupić cywilne ODPOWIEDNIKI... ogólnie róznica jest taka jak między ORYGINALNYMI "ADIDAS" wyprodukowanych w Niemczech i "adidoss" z targu za 30zł.."

(Why ... "KUPCZAK" are better than "Wojas" etc. ?? ... I repeat it again, that I'd better prefer to give even 400 zloty for "KUPCZAKI", because it is difficult to find the appropriate civilian boots for 400 zloty... ... as a rule, the difference (between "Kupczak" and "Wojas") is just the same as between the original "Adidas" made in Germany and "adidoss" from the local market for just 30 zloty).

Among the other customer's reviews about these boots there were also: "... The boots by "Demar" are of higher quality than the "Wojas" boots, the first boots have more rigid out-soles and leather tops, and they need more time to "break in", but they will last longer than less durable "Wojas" boots with softer leather and stiffer rubber "rim" along the boot's sides. "Wojas" boots also feature thick laces which often use to be jammed in the clamp for laces in the centre of the lacing system. "Demar" boots, in opposite, show no problems with the same laces from the "Wojas" boots.

Both companies ("Demar" and "Wojas") are considered to have lower standards of production at a lower price, as compared with the original manufacturer. At present "Kupczak", the company-developer of the 928/MON boots is no longer manufacturing this model by contracts for the Polish Armed Forces.

There are almost no supplies of such boots on the military warehouses - the stocks of this model just have been exhausted over time, and that makes "Kupczak" 928/MON boots the true treasure for those who know such details and picky in footwear.

The original 928/MON boots by the original manufacturer are quite expensive, they are made in Poland only, where they stand about 650 zloty (157 Euros). But similar boots by "Wojas" can be found for just 150 zloty (36 Euros), and they can be manufactured in Slovakia or some other countries.

The sources of the photos and information:

http://abovetopsecret.com

http://allegro.pl (johny_malboro)

http://archiwum.allegro.pl

http://armyworld.pl

http://art-fox.pl

http://banzaj.pl

http://demar.com.pl

http://do.wp.mil.pl

http://gascolt.pl

http://gunrunnerhell.tumblr.com

http://ngt.pl

http://odkrywca.pl

http://olx.pl (Aleksander, Warszawa)

http://onlinemilitaria.com

http://pphu-kama.pl

http://skibicki.pl

http://specshop.pl

http://systemplus.sklep.pl

http://tablica.pl

http://uak-airsoft.com/images/grom5.jpg

http://usmilitariaforum.com

http://xarchiwum.pl

Exclusively for cartalana.com

We have much more interesting information on this site.

Click MENU to check it out!

∎ cartalana.com© 2009-2025 ∎ mailto: cartalana@cartalana.com