Rights Reserved - Free Access.

This digital object is protected by copyright and/or related rights. This digital object is accessible without charge, but its use is subject to written permission.

Unless expressly stated otherwise in the licensing conditions, you are free to make any of the acts permitted by your national copyright and related rights act, including browsing, printing and making a copy for your own personal purposes.

All other acts of reproduction and communication to the public are subject to the licensing conditions attached to the digital object.

ARMY BOOTS OF THE WORLD. REVIEWS

Important notice: we do not sell any boots! The prices are given for information purposes only!

Greece ![]()

The Greek army boots ("Áρβυλα ελληνικού στρατού" - "Arbula ellinikos stratos") are used as a field footwear in all branches of the Armed Forces of Greece.

For many years they were unchanged in their design, and only recently, just 5 years ago, new versions of Greek army boots began to appear. This was due to the requirements of time and active participation of the Greek military in the UN and NATO peacekeeping and stabilization operations of the recent years.

The great bulk of military boots (about 85%), supplied to the Greek Army, Air Force, Navy and the Coast Guard, are manufactured by "PYRGOS" ("Pyrgos boots - Army Boots and boots Factory"). This Greek company also provides at least 3/4 of all its sales of military footwear to the civil specialty stores. This company was the first major domestic industrial corporation, which began supplying boots to the Armed Forces massively throughout the whole country.

"PYRGOS" company was founded in 1967 in Thessaloniki by Dimitrios P. Skoumpris, which was engaged in hand-made manufacturing of men's footwear in general, and military boots in particular. Since 1979 the company has expanded considerably and moved to the new production site just 8 kilometres from the city of Xanthi, where it is situated today. For such a small country like Greece, even in our days it is noteworthy that the total area of industrial sites and warehouses occupies about 20,000 square meters, 2,000 square meters from which are covered premises.

Around this same time, the progressive DMS (Direct Moulded Sole) method was introduced. This American technology allowed to attach the leather boot's top to the out- sole of vulcanized rubber, and such boots were light-weight and robust.

Just similarly to the combat boots of Norway and Israel, the military boots of Greece were the copies of the American army DMS boots, which were in use from the early seventies to the mid-eighties of the last century. The photo below shows the typical US military boots, issued by C.I.C. GENESCO company. This model was taken as an example to follow.

The tread pattern of the out-sole is a zigzag-type "Chevron", which was not changed at all, as well the design of the boot's top (made from strong smooth leather). As it was told before the Greek boots were of the DMS-type.

The "PYRGOS" company, led by Periklis and Panagiotis Skoumpris for the last 10 years, managed to get the ISO 9001 Quality System certificate in 1998, and from 2008 they started producing a sufficiently large range of boots, especially for the Army and the Air Force.

The most simple and applicable for the Greek climate are model C100 black smooth leather boots. This model was a basic one, having repeated almost entirely the American model, following the peculiarities up to the number of the lacing eyelets. However, there were minor differences too - they lack such element as notched leather about halfway up the lacing (as it was on the American sample, which had 4 pairs of eyelets in the lower part, a notch above, and 5 pairs of eyelets up the lacing). Also the Greek designers have added steel rivets at the on the both sides of the boot's top, in the lower part of the lacing gusset.

The top of the boot is made of soft and durable cowhide (the thickness is 1.8-2 mm), with hydrophobic impregnation, which withstands for at least 2 hours without water soaking. The tongue (thickness 1.2-1.4 mm) can withstand water at least an hour without getting wet inside. The tongue is gusseted almost to the "half-way" up the lacing. A removable insole is made of latex and the fabric, with a layer of activated carbon to absorb moisture and to eliminate unpleasant odours. The non-removable insole features reinforced steel arch support and is made of thick leather (3-4 mm of thickness), impregnated with tannins. The out-sole is made of solid vulcanized rubber, tread pattern is the standard American zigzag-type "Chevron". The range of sizes of the Greek army boots is from 37 to 51.

The boots model C200 is very similar to C100 model, except for the additional soft leather padding on top of the boot and the lacing system, which consists of nine pairs of simple round eyelets, which are divided into two parts by the notch: three pairs of eyelets form the lower part of lacing system, and six round eyelets form the upper part. With the exception of the padding "collar" on top, this model is a actually a full analogue of the American prototype.

Boots model C201 differ from model C200 by the presence of an additional layer of "glove"-type beige-coloured leather insulation inside the boot, the thickness of insulation is from 0.9 to 1.1 mm.

Leather upper 0.1 mm thinner than previous models.

Model C202 is just a modification of model C201 boots. In C202 boots the inner lining is made of textile material instead of leather, the thickness of the tongue is slightly less (1-1.2 mm) than in the full leather model (1.2-1.4 mm).

The boots of C200 series featuring double fastening (the laces and side zippers) are presented by model C220. The top of zipper is additionally fixed by "Velcro"-type clasp. The inner lining of these boots can be of two types: thin leather (code 221) or textiles (code 222), the anti-bacterial insoles are also added to all the versions of these boots.

In the Greek army they also use a kind of boots with two buckles on top. Such is the model C301, with represents by itself something like a hybrid type between the standard US-Greek model and French "Rangers" BMJA-65 boots. The manufacturer calls these boots the "FLUORESCENT SIGN" for some reason.

These lacing system of these boots, like of the French boots, consists of 6 pairs of round eyelets, and just the same simple system of two buckles. The innovation of these boots consists in an additional layer of the foamy rubber in the out-sole.

In 2013, the Armed Forces of Greece began using new boots model S401-402, which feature a new element - the damping insert in the rear sides of the boots.

This damping element has long been used in the military boots of many armies of the world. The model S401 inner insulating lining is made of "glove"-type leather, while the C402 model features "Cambrelle" lining.

Both models come with a removable leather-and-latex insoles, and the out-soles feature an additional cushioning layer of foamy rubber. The top five pairs of round eyelets were replaced by lacing hooks.

Responding to the demands of time and the need for Greek soldiers participation in the overseas operations, the Greek footwear manufacturers proposed a number of models for the hot and dry climate. Since sandy coloured boots get less heat from the sun and are less visible, the model C201 was designed in sandy colour, having got the name C211 "Sahara". Particularly there is no differences between these two models, except for the colour.

Similarly, model C220 (featuring lacing and zippers) was modified and named C230 "Desert Zipper". The top of these boots is made not of smooth leather, but of durable suede, and the zipper are very light-coloured, almost white

The subtypes of these boots vary in inner insulating layer material: thin leather (code 231) or textiles (code 232), but both models are supplied with removable cushioning antibacterial insoles.

The Greek military "desert" boots are presented not only by full-leather boots models, there are also the combined versions, made of suede and "Cordura" (nylon). For example one should mention model S1117 boots.

The top is made of light brown suede (the thickness is 1.8 mm). The inner lining is made of textiles, the suede parts of the top consist of toe, counter, soft patting "collar" on top, as well as the side strips and lacing system, which, in turn, consists of four pairs of "D"-shaped ring at the lower part, a pair of hook clamps above and three pairs of simple hooks for lacing on top. The sole is made of durable vulcanized rubber. The sizes of such boots range from 36 to 48.

To go beyond the products of a single manufacturer, even controlling the 3/4 of the market, it is worth mentioning an alternative producer of military footwear and equipment.

The second largest producer, which controls almost a quarter of the Greek market of military footwear and equipment is the so-called "Military Factory No 700" ("700ΣΕ" - "700 Στρατιωτικού Εργοστασίου"), located at Attica, in the very heart of Greece.

The production of "700ΣΕ" is compliant to the approved military specifications and characteristics of similar products by "PYRGOS". The following boots of this brand, positioned as the winter boots, cost about 116 Euros in Greece.

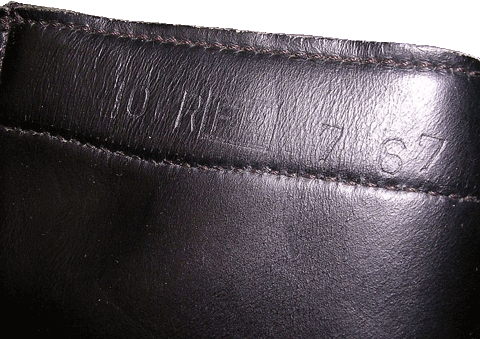

Among the manufacturers of Greek military boots, which were in use during the years 1960-1970s, one should mention "FLOREX" "ΦΛΟΡΕΞ". These "Goodyear welt construction" - type black grain leather boots feature stitched, glued and tucked solid vulcanized rubber out-sole with shallow grid-like tread pattern. The lacing system consists of eleven pairs of simple round eyelets, the boot's tongue is stitched to the mid of lacing. The stamp with model number and ID information is marked on the upper part of the boot's top.

The marking on the sole is: "ΦΛΟΡΕΞ ΕΛ&923#;ΗΝΙΚΟΣ ΣΤΡΑΤΟΣ", i.e. the name of the manufacturer and "Armed Forces (of Greece)", written inside the circle. The inscription on the heel shows: "ΦΛΟΡΕΞ" in the round circle and "ΕΛ&923#;.ΣΤΡΑΤΟΣ No 3 12/13" (the model number (No 3, 12/13)).

Like most recent military boots of Greece, these boots are actually the copies of contemporary American army boots. They Greek boots seem more rough, especially the heels joint to the outsole. The Greek ones have the same number of lacing eyelets, the construction is almost the same.

The out-sole tread pattern of the Greek army boots shows deep similarity with American examples of different years: the toe of the sole is reinforced with additional rubber layer similarly to the famous "Corcoran" jump boots. The stitching, gluing and tucking with nails is also the same.

The place and style of boots marking and the out-sole tread pattern are very similar to different US military boots, starting from low Russet service shoes of the year 1939, to high boots of Korean and Vietnam wars, manufactured by "Endicott-Johnson", "Light Tread" etc.

The sources of the photos and information:

http://pyrgos-boots.gr

http://army-market.gr

http://ellinikos-stratos.com

http://militaryphotos.net

http://airsoftcenter.gr

http://todocoleccion.net

http://varusteleka.fi

https://i.warosu.org

Exclusively for cartalana.com

We have much more interesting information on this site.

Click MENU to check it out!

∎ cartalana.com© 2009-2025 ∎ mailto: cartalana@cartalana.com