Rights Reserved - Free Access.

This digital object is protected by copyright and/or related rights. This digital object is accessible without charge, but its use is subject to written permission.

Unless expressly stated otherwise in the licensing conditions, you are free to make any of the acts permitted by your national copyright and related rights act, including browsing, printing and making a copy for your own personal purposes.

All other acts of reproduction and communication to the public are subject to the licensing conditions attached to the digital object.

ARMY BOOTS OF THE WORLD. REVIEWS

Important notice: we do not sell any boots! The prices are given for information purposes only!

Germany ![]()

Boots of Bundeswehr (Federal German Armed Forces) for "Paratroops" and "Infantrymen"

The "ankle boots" of Bundeswehr (this name was used for West German army before unification with East Germany, and retained its name further on) are among the most recognizable and popular types of military boots in many European countries. These boots embody the long tradition of the German army footwear. This is due not only to very high quality of materials and design, comfort and ease of use, attractive appearance and distinctive style, but also to their availability. Shoes, uniforms and different military stuff of the Bundeswehr are not prohibited for export and use abroad, in contrast to some other countries like Denmark, Sweden, Canada, etc....

There are different ways by which the army stuff (uniforms, backpacks, belts, tents, isolation mats, sleeping bags, tableware sets, soldiers folding knives, "Esbit" type pocket cooking ranges, gloves ...) and, of course, Bundeswehr boots, used and brand new get to their new owners. As for the army boots, not always the buyers can understand what boots did they purchase, the date of boots manufacture. It is not obvious in what period of time were they used.

Bundeswehr boots of 1970-1990s are very recognizable due to their traditional German design and good quality, perfect workmanship and good grip of the soles tread.

Brown-coloured boots were introduced circa 1971, having replaced high army boots of the so-called "Knobelbecher" - type, which were widely used for decades in the German army. "Knobelbecher" means "dice cup". This strange name appeared thanks to the specific sense of humor of the German soldiers. As these sturdy high boots were made of very thick and hard leather, the soldier's feet used to be clattering inside the boots very similar to the dice in a cup. The Dutch army has created quite a similar term, and even nowadays the Dutch army boots are still called "Legerkisten" or even "Legerlaarzen" ("army chests" and "army boxes" correspondingly).

The brown colour of the combat boots was widely spread in most countries of the world at that time.

In 1973, the Bundeswehr has switched to brown-coloured army boots almost completely, having left the "Knobelbecher"- type high boots only for official ceremonies, for use in German navy, air force, and for specific conditions (such as at low temperatures) as well.

From 1971 to 1975, the polyurethane outsole was not only glued, but also stitched along the edges of the outsoles. For this purpose the tread pattern of the outsole was slightly shifted from the edge of the sole closer to the center.

From 1975 to 1978 they produced the boots with the glued soles only. Since 1978, the Bundeswehr switches to black-colour boots instead of brown. Presumably, this was made due to the fact that black boots are less noticeable for the infrared sight. As a huge amount of brown boots have already been manufactured by that time, the soldiers were often ordered to repaint the issued brown boots to the newly authorized black colour by repeated applying black shoe polish.

In 1984 the army boots design was modified and lasted until the year 1993, when these boots were replaced by the new type boots called "Model 2000". Some boots, manufactured in the period 1984-1993 have been resoled with experimental soles of "Model 2000" type.

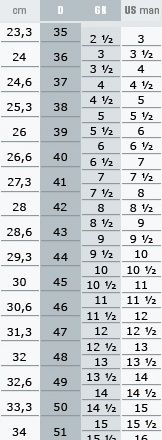

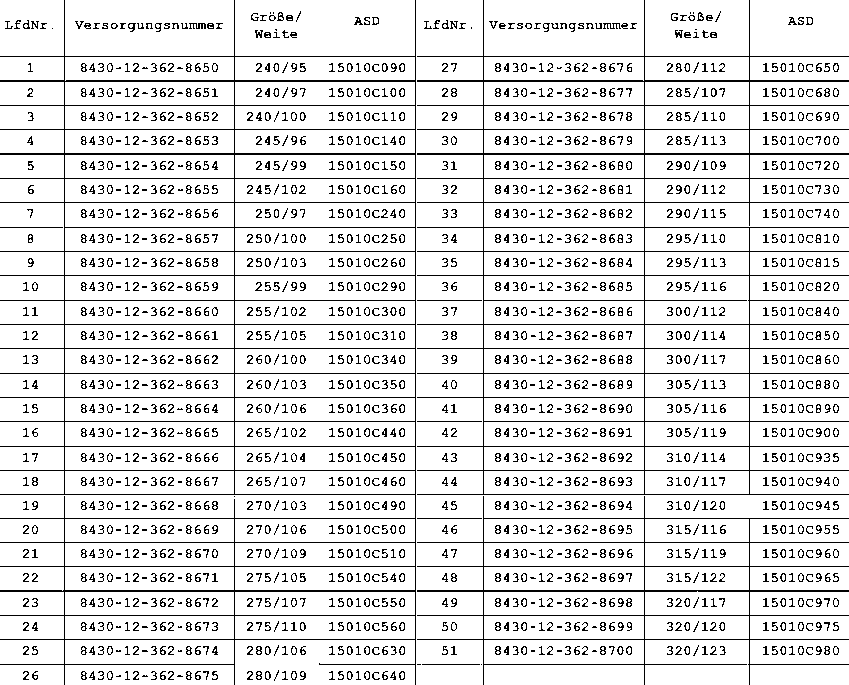

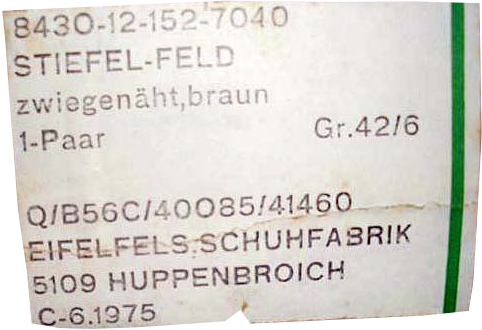

For each pair of boots the identification information (size and width, month and year of manufacture, manufacturer's code) is specifically indicated on the tongue, at the top inner side. Initially the size was specified in millimeters ("Mondopoint" system), later on - in the "European metric", e.g., 42 or 46.

Example of box marking (brown boots, European size).

The tread pattern of the classic German army boots, the so-called "Berghaken Profilsohlen", was very successful and well-developed. It was copied, for example, in the M-91 model Finnish Army boots.

The outsoles of German army boots were produced by many manufacturers, for example:

- "Continental" (among all the contract manufacturers of the Bundeswehr boots outsoles, this company produced the most hard and durable polyurethane outsoles, resistant to wear and tear on the typical city pavement).

- "Metzeler" - the most soft of all the outsoles, though the boots heels used to be worn out heavily on the asphalt);

- "Ir", "Tewa", "Winterberg", "Cosmoped", "SKYWALK" and the other were of medium softness (and wear resistance).

A very important issue is the choice of a good insole. The German statutory green plastic thin-mesh insole is one of the best options for good air circulation and comfort of wear. The only precaution that should be taken into account is the necessity to choose the exact size for the particular pair of boots, because the pressed and molded edges of the insoles can crumble if the size selection was wrong.

A curious fact - on some Russian-language forums the Bundeswehr "paratrooper's" and "infantry" boots are quite oftenly mixed, sometimes they are wrongly called the "corporal" boots, although the rank of corporal has never been used in the German army.

Actually, the aforementioned "paratrooper's" and "infantry" boots are quite different.

Let's consider all these boots in details.

The German "paratrooper's" boots (in German they are called "Fallschirm Springerstiefel" or "Fallschirmspringer-Schnurstiefel") have unpadded tongue, they are made of smooth black leather and feature yellow-coloured solid lining (soft padding plus thin soft "glove"-type leather) along the tibia to the top.

Such boots were made back in the 1960s. Further on, since 1990s the copies of such boots, with "Vibram"- type outsole, are still produced by commercial copy-cats like "MilTEC" or "MFH" in some variants: with steel toe-cap (yellow or black lining) or without steel toe-cap (orange lining).

"Die Fallschirmspringer-Schnurstiefel" ("Paratrooper's top-laced boots") were manufactured in 2 versions - depending on the outsole type.

Variant 1 This model did not feature reinforced counter, the tongue was unpadded, but the top part of the boots featured the inner layer of cushioning material (wadding).

Variant 2

In the year 2000, the boots were very similar to the Variant 1 boots, but featured hook clamps for laces fixation.

The "Infantry"-type boots differ from the "paratrooper's" boots (which, as we remember, featured the inner layer of cushioning material (wadding), unpadded tongue, also they lacked the counter reinforcement).

The Germans themselves do not call these boots the "infantry", preferring to call them brown or black lace-up boots.

Brown boots ("Die braunen Schnurstiefel"):

Variant 1 - there outsoles are stitched and glued

Variant 2 - glue-fixed outsoles.

The tongues of these boots are padded, as different from the bootlegs. This is not "paratrooper's" boots, but the ordinary Bundeswehr boots!

Black boots ("Die schwarzen Schnurstiefel"):

Variant 1: "Der Glattleder-Schnurstiefel" (Smooth leather lace-up boots)

Variant 2: "Genarbtes Leder, durchgeschnurt" (Grain leather, lace -through boots (without hook clamps))

Variant 3a: "Genarbtes Leder, Schnurung mit Haken (Grain leather, lace-through boots with hook clamps)

Variant 3b: "Genarbtes Leder, Schnurung mit Haken und neuer Sohle" (Grain leather, lace-through boots with hook clamps and new type outsoles)

All these Variants (1, 2, 3a, 3b) are what we call the "infantry" boots. This is not "paratrooper's" boots.

Thus, the "paratrooper's" boots have undergone few changes: new tread outsole + hook clamps in some later models.

The evolution of German army boots of the second half of the 20 century:

Bundeswehr Boots for Jungle and Desert Regions by "Baltes"

After the unification of Germany (in fact, it was the absorption of the East Germany by the West Germany), crush of the Soviet Union and collapse of the Warsaw Pact, the geopolitical situation in Europe has changed dramatically. The economy and industry of the united Germany has firmly taken the leading position in continental Europe, so the role of armed forces of the new Germany increased respectively.

In early 1990s, Bundeswehr soldiers were involved in operations abroad in accordance with the UN or the OSCE mandates only. But later a new idea has become wide-spread: Germany, as an active and powerful NATO and EU member should actively ensure collective security and peace in the world.

The events of the Second World War have been gradually forgotten, and after the war in Yugoslavia the Bundeswehr troops have increasingly been used outside the German territory as a peacekeeping force on various theaters of war under the auspices of NATO and the UN. Moreover, the NATO allies have become actively interested in German soldiers participation in all these operations.

So, since 1991, the Bundeswehr has been involved in providing combat operation in the Persian Gulf (against Iraq): German soldiers were involved in searching for mass destruction weapons and neutralization of sea and land mines. Later they supported humanitarian activities in Cambodia (1991-1993) and Somalia (1992-1994), then - in Rwanda, Georgia, East Timor, Afghanistan, Uzbekistan, Bosnia and Herzegovina, in the Horn of Africa, Ethiopia / Eritrea, Sudan and Macedonia. One should notice, that Germany has also been taking active part in highly controversial actions aimed at supporting Albanian separatists of Kosovo. Further on Germans participated in NATO operations in Afghanistan and Iraq, the mostly in the countries with hot and arid and wet climates, very distinctive from the European theater of operations.

Thus, the urgent need in the appropriate self-developed equipment, footwear and uniforms became the matter of concern for the Bundeswehr. Since Germany has always been a large and self-sufficient military power with long military traditions, the issue of the purchase of clothing, boots and other equipment from any other NATO allies (France, the UK or the USA) was not even raised. It was decades earlier, when the French, the Brits and the Americans had to solve, each one in its own way, these problems in the course of military conflicts in the jungles of Indochina and Latin America, in the deserts of North Africa and the Middle East.

The German company "Th. Baltes Schuhfabrik GmbH & Co. KG / Baltes Schuhtechnik und Arbeitsschutzprodukte GmbH" is more commonly known by the acronym - the trademark "BALTES".

The company was founded in 1872 and has never changed its owners for five generations. It successfully coped with the task of creating a specialized army footwear hot and arid (desert) and hot and humid tropical climate (the jungle).

The company's production facilities are located in a small town of Heinsberg, the Federal land of North Rhine-Westphalia, almost on the Dutch border (to the north of Aachen and to the west of Cologne and Solingen). "BALTES" - one of the few modern companies, which in principle refused to transfer their production in the countries of Southeast Asia, making its products in Germany only, from the raw materials of German and European tanneries. This allowed the company to maintain high quality of its products. In addition to the army and police footwear, the company also offers a specialized sports, fire, safety, labor, mountain boots, boots and "ankle boots", casual boots and parade boots, being a versatile boots manufacturer.

We, the potential buyers of army boots from "BALTES", should take into account, that the footwear from this manufacturer is 2 millimeters longer if to compare with the similarly sized boots from the other manufacturers. For example, if "MEINDL" or "HAIX" boots of sizes 43 and 41 are respectively equal to 275 and 260 mm in "Mondopoint" system, the "BALTES" boots of sizes 43 and 41 will be equal to 277 and 262 mm respectively). This fact, quite possibly related to the special form and structure of the outsole construction.

Contract Bundeswehr Desert Boots for the Hot and Arid Climate, Sandy-Colored (Wüstenstiefel der Bundeswehr - Kampfstiefel) from "Baltes"

The outsoles of these boots are made of polyurethane, a composite material, consisting of isocyanate resin and a mixture of high molecular weight spirits. They are of medium hardness, sand-coloured, lightweight, durable and resistant to wear. According to the requirements of the Bundeswehr Regulations for the footwear design and materials, the outsoles are to be anti-static ("Antistatisch"), oil-and petrol (gasoline)-resistant ("Oel-und-Benzinfest"), acid and alkali-resistant and abrasion-resistant.

The manufacturer's logo is indicated on the heel and on the sole, as well as the specific boot sizes in the "Mondopoint" and European systems. Sometimes, the logo is not indicated.

The boots top is made of composite materials (49% - leather (suede) and 51% - reinforced polyamide (Cordura), the mesh insole: 100% polyamide).

The composition of these boots is as follows:

- The toe and the counter, the welts with speed-lacing eyelets and backside strip are made of hydrophobic sand-coloured suede (black leather is used for jungle boots to be described below);

- The tongue and the upper are made of lightweight and breathable material - Cordura (polyamide), with padded collar on the top of the boots;

- The reinforcing backside inserts, also protecting the malleolus bones are made of sand-coloured suede (thick dark olive coloured Cordura is used for jungle boots).

Contract Bundeswehr Boots for a Hot and Humid Tropical Climate, Black and Green (Bundeswehr Tropenstiefel - Kampfstiefel)

From a distance and by colour the German army "jungle- boots" resemble the famous American "jungle-boots"; but only from a distance. A closer look reveals significant differences between these types of boots for the jungle, starting from design and ending with materials used. The common elements of German and American boots are the location and the material (stainless steel non-ferrous metal) of two mesh eyelets (drain holes) on the inner sides of the boots - it is 100% American design, allowing the wearer to withdraw quickly the water from the boot, then to dry and ventilate the feet inside. The principle of this system is not in preventing any ingress of water into the boots, like the rubber footwear does, with all disadvantages of this concept. Just the opposite, the water can easily get in the boots, but not less easily it can be withdrawn.

The back side of the Bundeswehr "BALTES" boots with loops for laces wrapping around is already different: the backside strips with loops are made of leather, unlike cordura or canvas (in early models) in the American jungle boots.

The boots top is composite very similar to the "desert" boots: (black smooth "hydrophobic" (i.e. specially treated and impregnated) leather and polyamide fabric (Cordura), mesh insole is 100% polyamide). The boot's toe and heel welts with speed lacing eyelets are made of genuine leather; the tongue and the reinforcing inserts sewn opposite to the malleolus bones and the top are made of Cordura, lightweight and breathable material. A thick cushion on top of the boots provide additional comfort of wear and protection against water, dust and small stones.

PU (polyurethane) outsole is medium hard, black, durable, lightweight and resistant to wear. Deep tread pattern, as well as the sole construction were designed by the manufacturer independently and does not copy the ideas of any other companies.

The inscription on the outsole says: "ANTISTATISCH, OEL U. BENZINFEST", that means "Non-conductive (anti-static) and oil-petrol (gasoline)-resistant". Also these outsoles are acid-, alkali- and wear-resistant.

The footwear lacing accessories include one locking hook-clamp and six speed lacing "MARK" eyelets, the same as in the "desert" boots and "jungle-boots" from "BALTES" company. The eyelets by "MARK" are also used in the footwear of the armed forces of UK, Denmark, the Netherlands and some other countries.

A rectangular leather patch of sand or black colour is sewn on the tongue indicating the boot size in "Mondopoint" system (e.g. 277 194) and the width. This information is shown in the in the upper row. In the lower row the four digits with the month and the year of manufacture (e.g., 0406 means April 2006) and the manufacturer's code, usually consisting of 2-4 digits, are indicated. All these numbers are pricked out by small dots.

The flap of the "jungle boot's" tongue is closed (sewn to the top of the tongue over the entire height of the boots) in order to protect the feet from dust, sand and other small particles, similarly to the "desert boots".

Police and Special Forces Boots by "Baltes"

We should also mention another kind of the same type German boots, which, on the other hand, can not be unambiguously attributed to the desert or tropical boots. We are talking about the police and special forces boots, designed for use in urban environments and indoors.

With a certain similarity with the German jungle boots, they differ in a number of features: colour (black), materials, some details of construction and the outsole are very different.

The outsole is multi-layer in construction, direct-mold, it's more "streamlined" and soft, without sharply protruding hooks tread. It is made of nitrile rubber ("Nitrilkautschuk-Sohle" in German), as well as brothers-in-class, it is antistatic and resistant to oil, petrol (gasoline), acid, alkali. These outsole is wear-resistant too. But these advantages have their "dark side": if this material if not properly stored (in dry hot places or even in the sun), it should crack from drying out. This is the reverse side of the convenience and flexibility of nitrile rubber.

The boot-top is made of black polyamide, which is softer in touch, the welt on top is padded with leather "collar", the tongue is made of leather and is higher in length, thus providing additional protection for the lower front side of the feet. Similarly to Bundeswehr desert and Jungle boots, the tongue of each boot also features a rectangular leather label (patch) with indication of size and fullness, month and year of production, and the code of manufacturer.

The lacing accessories feature "speed-lacing system". In comparison with German jungle and desert boots, these boots have an additional pair of eyelets (seven "MARK"-labeled eyelets + hook clamp for laces).

All of the abovementioned boots by "BALTES" company are lightweight and sturdy, comfortable and practical, with well-fixed ankle protector that provides good adhesion to most surfaces. General construction and design allow favorable microclimate for feet and comfort in use.

Bundeswehr Black Lace-up Boots Variant 1: With Smooth Leather (Die Schwarzen Schnurstiefel Variante 1: Der Glattleder-Schnurstiefel)

Black boots of the German Army (Bundeswehr) are made of genuine smooth leather, they feature leather intermediate sole + polyurethane tread. According to the Bundeswehr footwear classification, they are called: "Die schwarzen Schnurstiefel Variante 1: Der Glattleder-Schnurstiefel" (Black leather lace-up boots variant 1: with smooth leather).

The boots size is indicated in the "Mondopoint" system, i.e. in millimetres. The 8-eyelet speed-lacing system is provided with the help of non-ferrous metal loops, manufactured by the "STOCKO" company, a contract provider of the Bundeswehr.

The boot's leather padded tongue is sewn to the boots top on the level of the sixth eyelet of the speed-lacing system, if to count upwards from down. So one can step into a puddle almost up to this level without ingress of water inside. Under condition of regular treatment with quality boot cream the boots leather doesn't get wet. The heel is reinforced with an additional layer of thick leather, which provides good ankle fixation and protection from dislocations.

On a sample photo one can see durable but flexible leather and thick leather intermediate sole, fixed together with polyurethane tread by an adhesive is manufactured by "Continental" company.

Unlike modern direct-moulded boots with soft rubber outsoles (which are practically not a subject of repair), the "leather+ polyurethane outsole" adhesive mounting method allows one to repair such boots by almost any cobbler and even to replace the outsole completely when needed.

These boots are no longer produced because of the high complexity of the handmade process and need in expensive materials. Modern industry has long been focused on the manufacture of disposable items, which can not be repaired.

"BW Kampfstiefel Typ 2000" ("Bundeswehr Type 2000 Combat Boots")

More recent, but less successful "Model 2000" Bundeswehr boots (so-called "BW Kampfstiefel Typ 2000") have serious constructive defects that occur over time. Even if not to wear, but just to store them (washed clean, polished with a good cream ("KIWI", for example) and filled-in with crumpled paper to keep the correct form), sooner or later the outsoles start to peel off, and then grey foam layer between the leather innersole and thick rubber tread crumbles and decomposes. After that, these boots are not a subject to repair - leather intermediate layer is treated with a kind of glue which can not be eliminated. Moreover, most of the new rubber soles in the cobbler's workshops are no longer flat, but with the folds for sewing, and the cost of the works would be too high.

Bundeswehr boots of "Model 2000" had been manufactured, probably in cheap South-East Asian countries. Sometimes on web-sites the seller shamefully write "Import", without specifying the country of production. The outsoles of such boots are marked with "the head of an Indian" logo. These boots are designed for use within a few years, followed by a self-destruction.

The open foam layer in the boots sole is a dead-end idea, in my opinion. This foam layer should be protected from all the sides by more durable outer layer. This lack of "Model 2000" Bundeswehr boots was corrected in next generation boots - "Model 2005", developed by "HAIX" company.

The outsole of the "Model 2000" type boots can hardly be robust and reliable because the foam layer is highly water- absorbing. The glue should be washed-out sooner or later, even if the outsides of the open foam layer would be treated with special means.

On this photo one can see just a "funny replica" of the "BW Kampfstiefel TYP 2000" from "MFH" ("Max Fuchs of Hinterschmiding"), a manufacturer similar to "Mil-Tec" ("Sturm", "MILTEc", "TSR"="Thomas Sturm of Rottenburg"), with their manufacturing sites in China.

The boots on this photo are designed for "military style" lovers and walks on the city pavement. Such boots have to be worn carefully and without any "extreme" stresses. Only from a distance such boots look similar to the original "Model 2000" type boots (which are faulty as well due to their foam layer "weak spot", as it was described before).

Even on the photo one can see poor quality and not accurate style of manufacturing. The differences from the original boots are clearly visible, and if to put these boots and the original boots nearby and just to touch the corresponding elements of the two samples, the differences are very evident.

My personal experience of using two pairs of "Model 2000" boots gave the following results: one pair was kept in storage and I even had no chance to wear them; the second pair was in use just for couple months. But the result was the same - de-lamination of the outsoles on both pair. Several friends of mine have faced with the same problems.

"Kampfstiefel Model 2005/2007" is the development of the "Model 2000" boots. The new type of boots feature single outsole with no open layers (actually, the layers of the outsole are "hidden" inside for robustness and durability). However, there are still a lot of fakes, and especially of "HAIX Model 2005". Various Internet forums are dedicated to consideration of the peculiar boots construction details and explanations how to distinguish the original boots from the fake ones. Sometimes they "dig" very deeply and discuss such peculiarities as the quality of the sole casting (the outsole surface should be smooth, without cracks and wrinkles, which definitely show that the components of the outsole material melted evenly); they consider such details as colour of the insole inside the boot and peculiarities of the thread (in this example, black filament), and the width of the stitches (narrow or wide), and the shape of the upper "collar" (wrinkle-free leather and straight edge), the height and other essential elements of construction as non-marking soles, manufacturer's code, embossed on the tongue, the quality of the lacing hinges (they must keep the laces firmly and not allow to scroll ...).

One has to learn these peculiarities to understand the little things and not to buy a fake for the price of the original.

It could be funny to visit a military surplus shops after reading such web-forums. Just a hypothetic situation: a seller tries to sell you a fake saying something like: "I could recommend you these boots: very good quality, I have had two pairs of such boots, very soft and durable...blah-blah-blah... , but after scrupulous consideration you can find very suspicious manufacturer's code of such boots, and/or see not correct thread etc... . And you have no doubt already, you are not going to buy this fake, you save your money for something better, and you even can tell the seller about the peculiarities of this bad goods....

Actually, "Kampfstiefel Model 2005/2007" appeared to be a response to the identified problems in the "Kampfstiefel Model 2000", and the old faults were eliminated in the new model. The main problem of the "Model 2000" were solved: the crumbly open-layered outsole became closed, general design and lacing system were improved. The boots of the "Model 2005/ 2007" (of course, the original ones, not copies!) have got quite good reviews.

Sources of the information and images:

http://multi-board.com

Exclusively for cartalana.com

We have much more interesting information on this site.

Click MENU to check it out!

∎ cartalana.com© 2009-2025 ∎ mailto: cartalana@cartalana.com